Are you a seasoned Multicraft Operator (MCO) seeking a new career path? Discover our professionally built Multicraft Operator (MCO) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

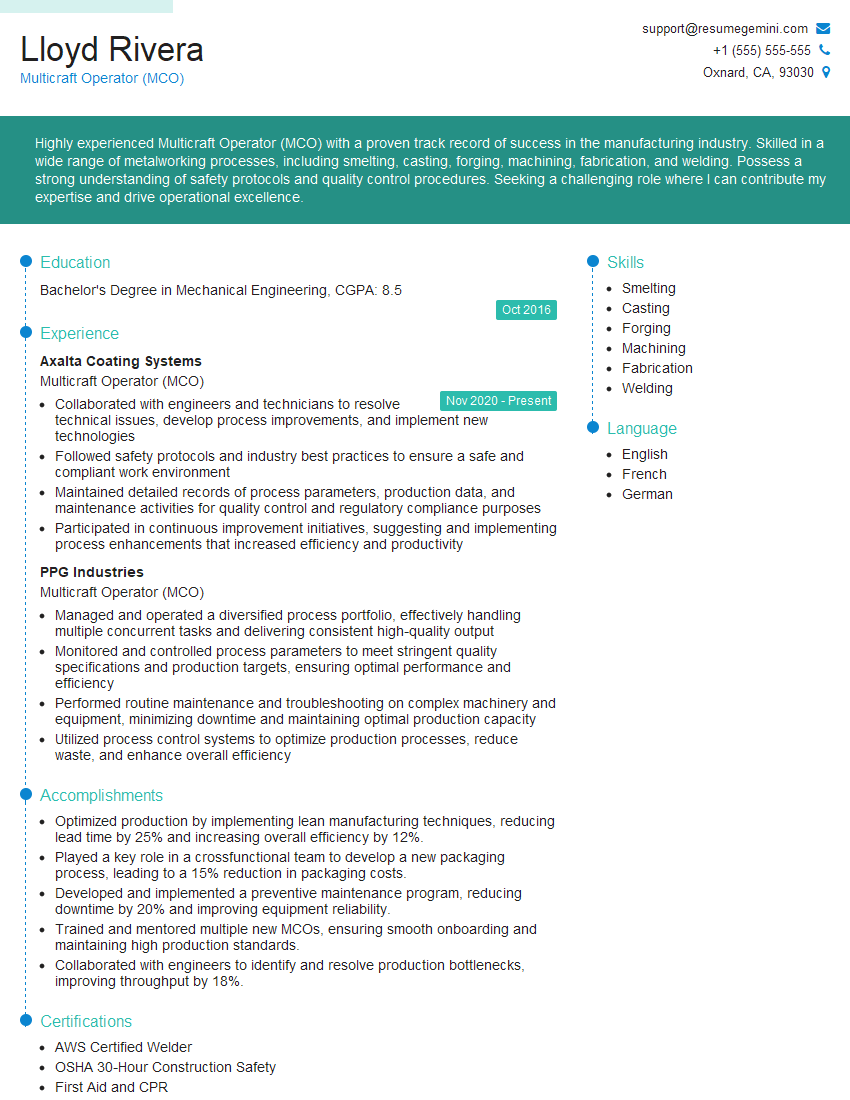

Lloyd Rivera

Multicraft Operator (MCO)

Summary

Highly experienced Multicraft Operator (MCO) with a proven track record of success in the manufacturing industry. Skilled in a wide range of metalworking processes, including smelting, casting, forging, machining, fabrication, and welding. Possess a strong understanding of safety protocols and quality control procedures. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Bachelor’s Degree in Mechanical Engineering

October 2016

Skills

- Smelting

- Casting

- Forging

- Machining

- Fabrication

- Welding

Work Experience

Multicraft Operator (MCO)

- Collaborated with engineers and technicians to resolve technical issues, develop process improvements, and implement new technologies

- Followed safety protocols and industry best practices to ensure a safe and compliant work environment

- Maintained detailed records of process parameters, production data, and maintenance activities for quality control and regulatory compliance purposes

- Participated in continuous improvement initiatives, suggesting and implementing process enhancements that increased efficiency and productivity

Multicraft Operator (MCO)

- Managed and operated a diversified process portfolio, effectively handling multiple concurrent tasks and delivering consistent high-quality output

- Monitored and controlled process parameters to meet stringent quality specifications and production targets, ensuring optimal performance and efficiency

- Performed routine maintenance and troubleshooting on complex machinery and equipment, minimizing downtime and maintaining optimal production capacity

- Utilized process control systems to optimize production processes, reduce waste, and enhance overall efficiency

Accomplishments

- Optimized production by implementing lean manufacturing techniques, reducing lead time by 25% and increasing overall efficiency by 12%.

- Played a key role in a crossfunctional team to develop a new packaging process, leading to a 15% reduction in packaging costs.

- Developed and implemented a preventive maintenance program, reducing downtime by 20% and improving equipment reliability.

- Trained and mentored multiple new MCOs, ensuring smooth onboarding and maintaining high production standards.

- Collaborated with engineers to identify and resolve production bottlenecks, improving throughput by 18%.

Certificates

- AWS Certified Welder

- OSHA 30-Hour Construction Safety

- First Aid and CPR

- NCCER Core

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Multicraft Operator (MCO)

- Highlight your experience in a variety of metalworking processes, as well as your ability to operate and maintain complex machinery.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on production.

- Showcase your knowledge of safety protocols and quality control procedures.

- Include examples of your ability to troubleshoot and resolve equipment malfunctions.

- Emphasize your teamwork skills and ability to collaborate with others.

Essential Experience Highlights for a Strong Multicraft Operator (MCO) Resume

- Operate and maintain a variety of metalworking equipment, including smelters, casting machines, forging presses, machining centers, and welding stations.

- Interpret technical drawings and specifications to fabricate and assemble metal components according to design requirements.

- Perform welding operations using various techniques, including MIG, TIG, and stick welding.

- Conduct quality control inspections to ensure that fabricated components meet specified standards.

- Troubleshoot and resolve equipment malfunctions to minimize downtime and maintain production efficiency.

- Adhere to safety protocols and maintain a clean and organized work environment.

- Collaborate with other team members to achieve production goals and improve processes.

Frequently Asked Questions (FAQ’s) For Multicraft Operator (MCO)

What is the role of a Multicraft Operator (MCO)?

A Multicraft Operator is a skilled tradesperson who operates and maintains a variety of metalworking equipment to fabricate and assemble metal components according to design specifications.

What are the key skills required for a successful Multicraft Operator?

Key skills include proficiency in a range of metalworking processes, including smelting, casting, forging, machining, fabrication, and welding. Strong attention to detail, problem-solving abilities, and a commitment to safety are also essential.

What industries employ Multicraft Operators?

Multicraft Operators are employed in a variety of industries, including manufacturing, construction, automotive, and aerospace.

What are the career advancement opportunities for Multicraft Operators?

With experience and additional training, Multicraft Operators can advance to supervisory or management positions, or specialize in a particular metalworking process.

How can I prepare for a career as a Multicraft Operator?

Consider pursuing a vocational or technical degree in welding, machining, or a related field. Hands-on experience through internships or apprenticeships is also valuable.

What are the safety precautions that Multicraft Operators must follow?

Multicraft Operators must wear appropriate safety gear, including gloves, safety glasses, and earplugs. They must also be aware of the potential hazards associated with working with heavy machinery and molten metal.

How can I stay up-to-date on the latest advancements in metalworking?

Attend industry conferences, read trade publications, and network with other professionals to stay abreast of new technologies and best practices.

What are the ethical considerations for Multicraft Operators?

Multicraft Operators must maintain high standards of integrity and professionalism. This includes adhering to safety protocols, using equipment responsibly, and avoiding any unethical or illegal activities.