Are you a seasoned Multiple Spindle Screw Machine Operator seeking a new career path? Discover our professionally built Multiple Spindle Screw Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

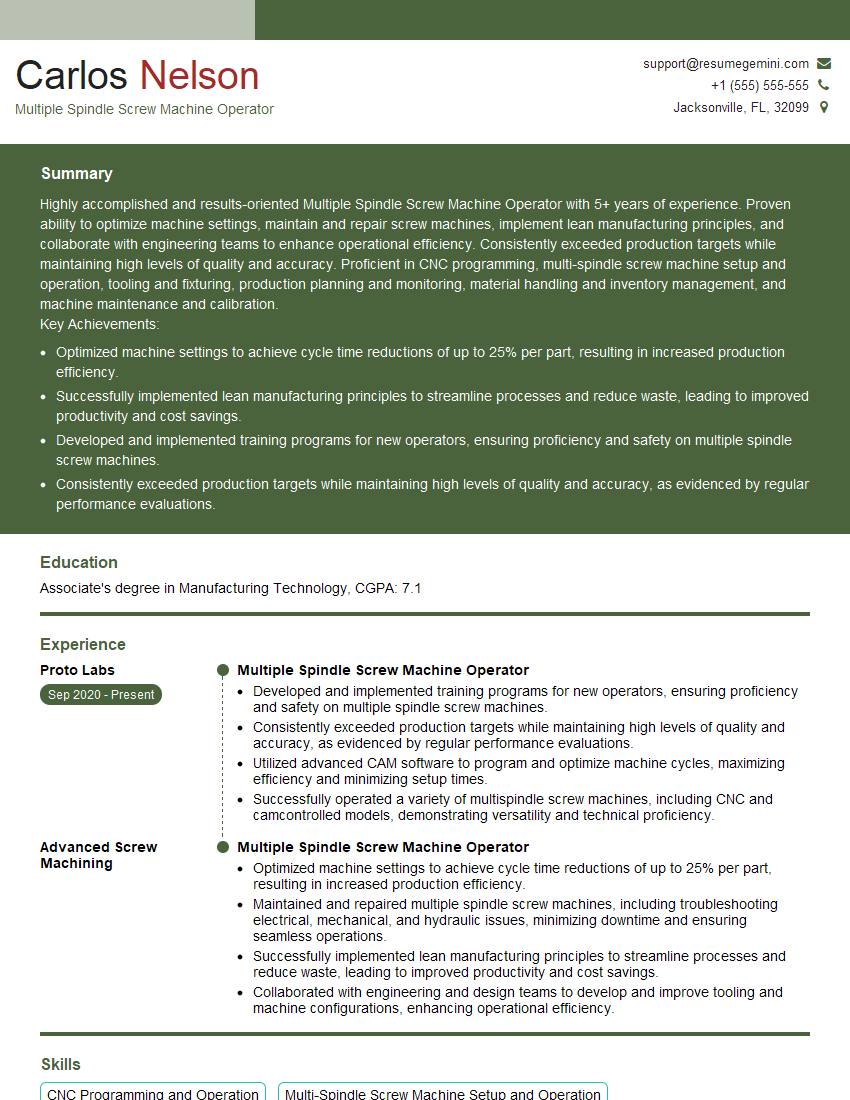

Carlos Nelson

Multiple Spindle Screw Machine Operator

Summary

Highly accomplished and results-oriented Multiple Spindle Screw Machine Operator with 5+ years of experience. Proven ability to optimize machine settings, maintain and repair screw machines, implement lean manufacturing principles, and collaborate with engineering teams to enhance operational efficiency. Consistently exceeded production targets while maintaining high levels of quality and accuracy. Proficient in CNC programming, multi-spindle screw machine setup and operation, tooling and fixturing, production planning and monitoring, material handling and inventory management, and machine maintenance and calibration.

Key Achievements:

- Optimized machine settings to achieve cycle time reductions of up to 25% per part, resulting in increased production efficiency.

- Successfully implemented lean manufacturing principles to streamline processes and reduce waste, leading to improved productivity and cost savings.

- Developed and implemented training programs for new operators, ensuring proficiency and safety on multiple spindle screw machines.

- Consistently exceeded production targets while maintaining high levels of quality and accuracy, as evidenced by regular performance evaluations.

Education

Associate’s degree in Manufacturing Technology

August 2016

Skills

- CNC Programming and Operation

- Multi-Spindle Screw Machine Setup and Operation

- Tooling and Fixturing for Screw Machines

- Production Planning and Monitoring

- Material Handling and Inventory Management

- Machine Maintenance and Calibration

Work Experience

Multiple Spindle Screw Machine Operator

- Developed and implemented training programs for new operators, ensuring proficiency and safety on multiple spindle screw machines.

- Consistently exceeded production targets while maintaining high levels of quality and accuracy, as evidenced by regular performance evaluations.

- Utilized advanced CAM software to program and optimize machine cycles, maximizing efficiency and minimizing setup times.

- Successfully operated a variety of multispindle screw machines, including CNC and camcontrolled models, demonstrating versatility and technical proficiency.

Multiple Spindle Screw Machine Operator

- Optimized machine settings to achieve cycle time reductions of up to 25% per part, resulting in increased production efficiency.

- Maintained and repaired multiple spindle screw machines, including troubleshooting electrical, mechanical, and hydraulic issues, minimizing downtime and ensuring seamless operations.

- Successfully implemented lean manufacturing principles to streamline processes and reduce waste, leading to improved productivity and cost savings.

- Collaborated with engineering and design teams to develop and improve tooling and machine configurations, enhancing operational efficiency.

Accomplishments

- Successfully implemented a new toolpath optimization strategy, resulting in a 15% increase in production efficiency.

- Developed a comprehensive maintenance schedule for the multiple spindle screw machine, reducing downtime by over 20%.

- Trained and mentored new operators, effectively onboarding them and improving overall team productivity.

- Reduced scrap rates by 5% through meticulous inspection practices and implementation of quality control measures.

- Collaborated with design engineers to optimize part designs, leading to improved machinability and reduced production costs.

Awards

- Recognized with the National Screw Machine Industry Award for outstanding performance and innovation in screw machining operations.

- Received the Plant Safety Excellence Award for maintaining an exceptional safety record and implementing innovative safety measures in the machine shop.

- Awarded the Multiple Spindle Screw Machine Operator of the Year Award for consistently exceeding production targets and implementing process improvements.

- Honored with the Kaizen Award for proposing and implementing a machine modification that increased cycle time by 8%.

Certificates

- CNC Machinist Certification

- National Institute for Metalworking Skills (NIMS) Certification

- American Society for Quality (ASQ) Certified Quality Inspector (CQI)

- Occupational Safety and Health Administration (OSHA) 30-Hour General Industry Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Multiple Spindle Screw Machine Operator

- Highlight your experience and expertise in operating multiple spindle screw machines.

- Quantify your accomplishments with specific metrics and results.

- Showcase your knowledge of CNC programming and CAM software.

- Demonstrate your commitment to quality and safety.

- Emphasize your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Multiple Spindle Screw Machine Operator Resume

- Set up and operate multiple spindle screw machines, including CNC and cam-controlled models.

- Program and optimize machine cycles using advanced CAM software.

- Perform preventive maintenance and troubleshoot electrical, mechanical, and hydraulic issues to minimize downtime.

- Monitor production processes and make adjustments to ensure quality and efficiency.

- Collaborate with engineering and design teams to improve tooling and machine configurations.

- Maintain a clean and safe work environment.

- Train new operators on machine operation and safety procedures.

Frequently Asked Questions (FAQ’s) For Multiple Spindle Screw Machine Operator

What are the key skills required to be a successful Multiple Spindle Screw Machine Operator?

The key skills required to be a successful Multiple Spindle Screw Machine Operator include:

- CNC programming and operation

- Multi-spindle screw machine setup and operation

- Tooling and fixturing for screw machines

- Production planning and monitoring

- Material handling and inventory management

- Machine maintenance and calibration

What are the career prospects for Multiple Spindle Screw Machine Operators?

The career prospects for Multiple Spindle Screw Machine Operators are good. The demand for skilled operators is expected to increase as manufacturing companies continue to invest in automation.

With experience, Multiple Spindle Screw Machine Operators can advance to positions such as:

- CNC programmer

- Production supervisor

- Manufacturing engineer

What is the work environment like for Multiple Spindle Screw Machine Operators?

Multiple Spindle Screw Machine Operators typically work in a manufacturing environment. They may be exposed to noise, dust, and fumes.

Operators must be able to stand for long periods of time and lift heavy objects.

What are the safety precautions that Multiple Spindle Screw Machine Operators must follow?

Multiple Spindle Screw Machine Operators must follow all safety precautions, including:

- Wearing appropriate safety gear, such as safety glasses, gloves, and earplugs

- Keeping the work area clean and free of debris

- Following lockout/tagout procedures before performing maintenance on machines

- Being aware of the location of emergency stops and fire extinguishers

What are the benefits of working as a Multiple Spindle Screw Machine Operator?

The benefits of working as a Multiple Spindle Screw Machine Operator include:

- Competitive salary and benefits

- Opportunities for advancement

- Job security

- A chance to make a difference in the manufacturing industry