Are you a seasoned NC Machinist seeking a new career path? Discover our professionally built NC Machinist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

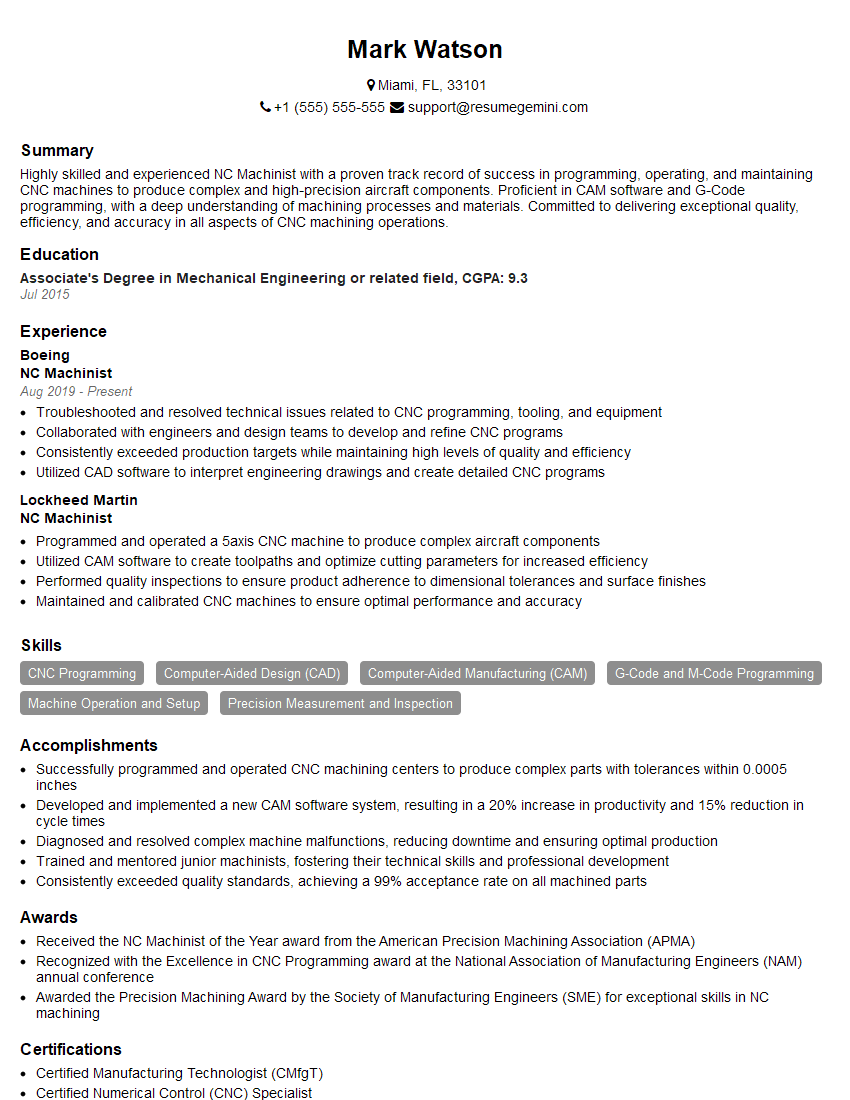

Mark Watson

NC Machinist

Summary

Highly skilled and experienced NC Machinist with a proven track record of success in programming, operating, and maintaining CNC machines to produce complex and high-precision aircraft components. Proficient in CAM software and G-Code programming, with a deep understanding of machining processes and materials. Committed to delivering exceptional quality, efficiency, and accuracy in all aspects of CNC machining operations.

Education

Associate’s Degree in Mechanical Engineering or related field

July 2015

Skills

- CNC Programming

- Computer-Aided Design (CAD)

- Computer-Aided Manufacturing (CAM)

- G-Code and M-Code Programming

- Machine Operation and Setup

- Precision Measurement and Inspection

Work Experience

NC Machinist

- Troubleshooted and resolved technical issues related to CNC programming, tooling, and equipment

- Collaborated with engineers and design teams to develop and refine CNC programs

- Consistently exceeded production targets while maintaining high levels of quality and efficiency

- Utilized CAD software to interpret engineering drawings and create detailed CNC programs

NC Machinist

- Programmed and operated a 5axis CNC machine to produce complex aircraft components

- Utilized CAM software to create toolpaths and optimize cutting parameters for increased efficiency

- Performed quality inspections to ensure product adherence to dimensional tolerances and surface finishes

- Maintained and calibrated CNC machines to ensure optimal performance and accuracy

Accomplishments

- Successfully programmed and operated CNC machining centers to produce complex parts with tolerances within 0.0005 inches

- Developed and implemented a new CAM software system, resulting in a 20% increase in productivity and 15% reduction in cycle times

- Diagnosed and resolved complex machine malfunctions, reducing downtime and ensuring optimal production

- Trained and mentored junior machinists, fostering their technical skills and professional development

- Consistently exceeded quality standards, achieving a 99% acceptance rate on all machined parts

Awards

- Received the NC Machinist of the Year award from the American Precision Machining Association (APMA)

- Recognized with the Excellence in CNC Programming award at the National Association of Manufacturing Engineers (NAM) annual conference

- Awarded the Precision Machining Award by the Society of Manufacturing Engineers (SME) for exceptional skills in NC machining

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Numerical Control (CNC) Specialist

- Certified Geometric Dimensioning and Tolerancing (GD&T) Professional

- Certified Master Inspector (CMI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For NC Machinist

- Highlight your proficiency in CNC programming languages, such as G-Code and M-Code.

- Demonstrate your familiarity with CAM software and its applications in optimizing cutting parameters.

- Showcase your experience in maintaining and calibrating CNC machines to ensure precision and accuracy.

- Emphasize your ability to troubleshoot and resolve complex technical issues related to CNC operations.

Essential Experience Highlights for a Strong NC Machinist Resume

- Program and operate 5-axis CNC machines to produce complex aircraft components according to engineering specifications.

- Utilize CAM software to create toolpaths and optimize cutting parameters for increased efficiency and productivity.

- Perform quality inspections to ensure adherence to dimensional tolerances and surface finishes, utilizing precision measurement tools.

- Maintain and calibrate CNC machines to ensure optimal performance, accuracy, and safety.

- Troubleshoot and resolve technical issues related to CNC programming, tooling, and equipment malfunctions.

- Collaborate with engineers and design teams to develop and refine CNC programs for improved production processes.

Frequently Asked Questions (FAQ’s) For NC Machinist

What is the primary role of an NC Machinist?

An NC Machinist is responsible for programming and operating computer-controlled CNC machines to produce high-precision components and parts.

What are the key skills required for an NC Machinist?

Essential skills include CNC programming, CAD/CAM software proficiency, precision measurement and inspection techniques, and troubleshooting abilities.

What industries employ NC Machinists?

NC Machinists are employed in various industries, including aerospace, automotive, manufacturing, and electronics.

What is the career advancement path for an NC Machinist?

With experience and additional training, NC Machinists can advance to roles such as CNC Programmer, Manufacturing Engineer, or Quality Control Manager.

What is the job outlook for NC Machinists?

The job outlook for NC Machinists is expected to grow due to the increasing adoption of CNC technology in various industries.

What are the educational qualifications required to become an NC Machinist?

Typically, an Associate’s Degree in Mechanical Engineering or a related field is required to qualify for NC Machinist positions.