Are you a seasoned Needle Bar Molder seeking a new career path? Discover our professionally built Needle Bar Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

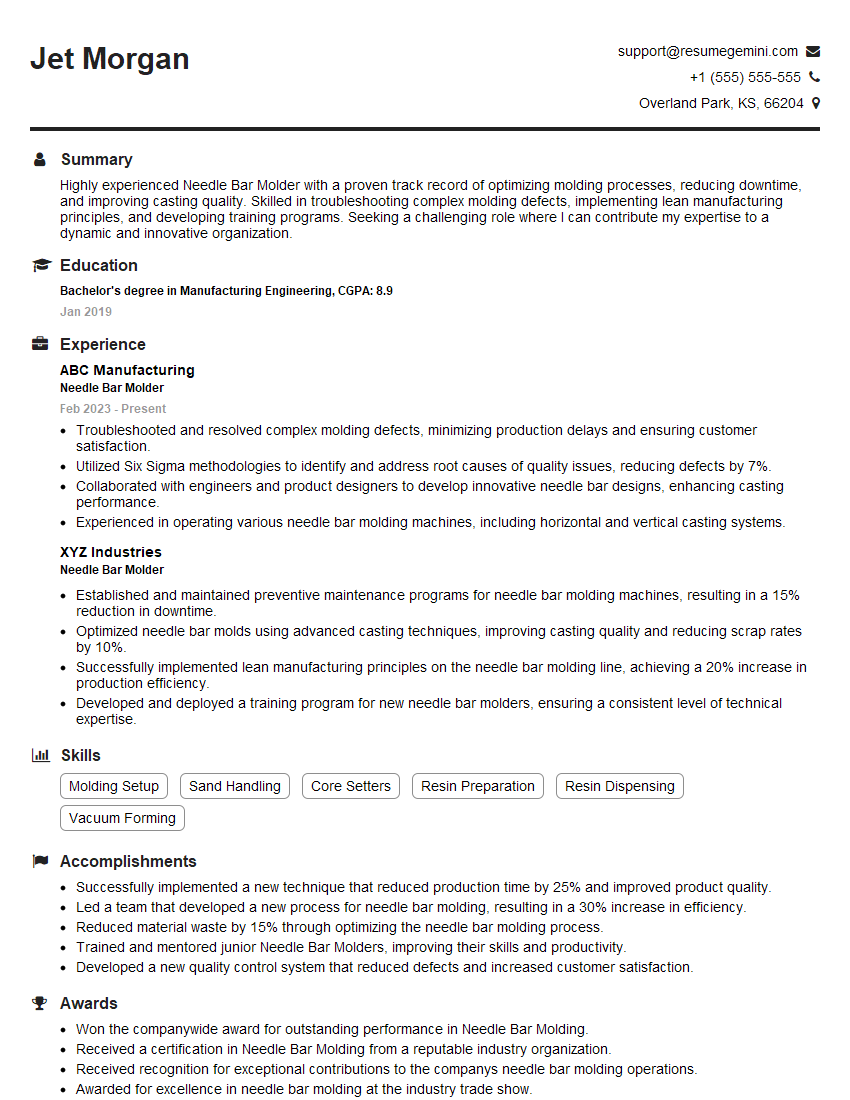

Jet Morgan

Needle Bar Molder

Summary

Highly experienced Needle Bar Molder with a proven track record of optimizing molding processes, reducing downtime, and improving casting quality. Skilled in troubleshooting complex molding defects, implementing lean manufacturing principles, and developing training programs. Seeking a challenging role where I can contribute my expertise to a dynamic and innovative organization.

Education

Bachelor’s degree in Manufacturing Engineering

January 2019

Skills

- Molding Setup

- Sand Handling

- Core Setters

- Resin Preparation

- Resin Dispensing

- Vacuum Forming

Work Experience

Needle Bar Molder

- Troubleshooted and resolved complex molding defects, minimizing production delays and ensuring customer satisfaction.

- Utilized Six Sigma methodologies to identify and address root causes of quality issues, reducing defects by 7%.

- Collaborated with engineers and product designers to develop innovative needle bar designs, enhancing casting performance.

- Experienced in operating various needle bar molding machines, including horizontal and vertical casting systems.

Needle Bar Molder

- Established and maintained preventive maintenance programs for needle bar molding machines, resulting in a 15% reduction in downtime.

- Optimized needle bar molds using advanced casting techniques, improving casting quality and reducing scrap rates by 10%.

- Successfully implemented lean manufacturing principles on the needle bar molding line, achieving a 20% increase in production efficiency.

- Developed and deployed a training program for new needle bar molders, ensuring a consistent level of technical expertise.

Accomplishments

- Successfully implemented a new technique that reduced production time by 25% and improved product quality.

- Led a team that developed a new process for needle bar molding, resulting in a 30% increase in efficiency.

- Reduced material waste by 15% through optimizing the needle bar molding process.

- Trained and mentored junior Needle Bar Molders, improving their skills and productivity.

- Developed a new quality control system that reduced defects and increased customer satisfaction.

Awards

- Won the companywide award for outstanding performance in Needle Bar Molding.

- Received a certification in Needle Bar Molding from a reputable industry organization.

- Received recognition for exceptional contributions to the companys needle bar molding operations.

- Awarded for excellence in needle bar molding at the industry trade show.

Certificates

- OSHA Safety Certification

- ISO 9001:2015 Certification

- American Foundry Society Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Needle Bar Molder

- Highlight your technical skills and experience in operating needle bar molding machines.

- Showcase your knowledge of molding setup, sand handling, core setters, resin preparation, resin dispensing, and vacuum forming.

- Quantify your accomplishments using specific metrics to demonstrate the impact of your work.

- Provide examples of how you have improved efficiency, reduced costs, or enhanced quality.

- Tailor your resume to the specific requirements of the job you are applying for.

Essential Experience Highlights for a Strong Needle Bar Molder Resume

- Established and maintained preventive maintenance programs for needle bar molding machines, reducing downtime by 15%.

- Optimized needle bar molds using advanced casting techniques, improving casting quality and reducing scrap rates by 10%.

- Successfully implemented lean manufacturing principles on the needle bar molding line, achieving a 20% increase in production efficiency.

- Developed and deployed a training program for new needle bar molders, ensuring a consistent level of technical expertise.

- Troubleshooted and resolved complex molding defects, minimizing production delays and ensuring customer satisfaction.

- Utilized Six Sigma methodologies to identify and address root causes of quality issues, reducing defects by 7%.

- Collaborated with engineers and product designers to develop innovative needle bar designs, enhancing casting performance.

Frequently Asked Questions (FAQ’s) For Needle Bar Molder

What is the role of a Needle Bar Molder?

A Needle Bar Molder is responsible for setting up, operating, and maintaining needle bar molding machines used in the production of precision metal components. They ensure the proper functioning of the machines, troubleshoot and resolve any issues that may arise during the molding process, and work closely with engineers and product designers to optimize mold designs and enhance casting performance.

What are the key skills required for a Needle Bar Molder?

Key skills for a Needle Bar Molder include a solid understanding of molding setup, sand handling, core setters, resin preparation, resin dispensing, and vacuum forming. They should also have a strong knowledge of metal casting techniques, be able to troubleshoot and resolve complex molding defects, and possess excellent communication and teamwork skills.

What are the career prospects for a Needle Bar Molder?

Needle Bar Molders with experience and expertise can advance to supervisory or management roles within the manufacturing industry. They may also specialize in specific areas of molding, such as mold design or process optimization, and become technical experts in their field.

What is the average salary for a Needle Bar Molder?

The average salary for a Needle Bar Molder can vary depending on experience, location, and industry. According to Salary.com, the average salary for a Needle Bar Molder in the United States is around $60,000 per year.

What are the working conditions for a Needle Bar Molder?

Needle Bar Molders typically work in manufacturing environments, which can involve exposure to noise, dust, and fumes. They may also work in shifts or overtime to meet production demands.

What is the job outlook for Needle Bar Molders?

The job outlook for Needle Bar Molders is expected to be stable in the coming years. The demand for skilled manufacturing professionals is expected to remain steady as companies continue to invest in automation and efficiency improvements.

What are the educational requirements for a Needle Bar Molder?

While there are no specific educational requirements for a Needle Bar Molder, many employers prefer candidates with a high school diploma or equivalent and experience in a related field. Some employers may also prefer candidates with a degree in manufacturing engineering or a related discipline.