Are you a seasoned Needle Felt Making Machine Operator seeking a new career path? Discover our professionally built Needle Felt Making Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

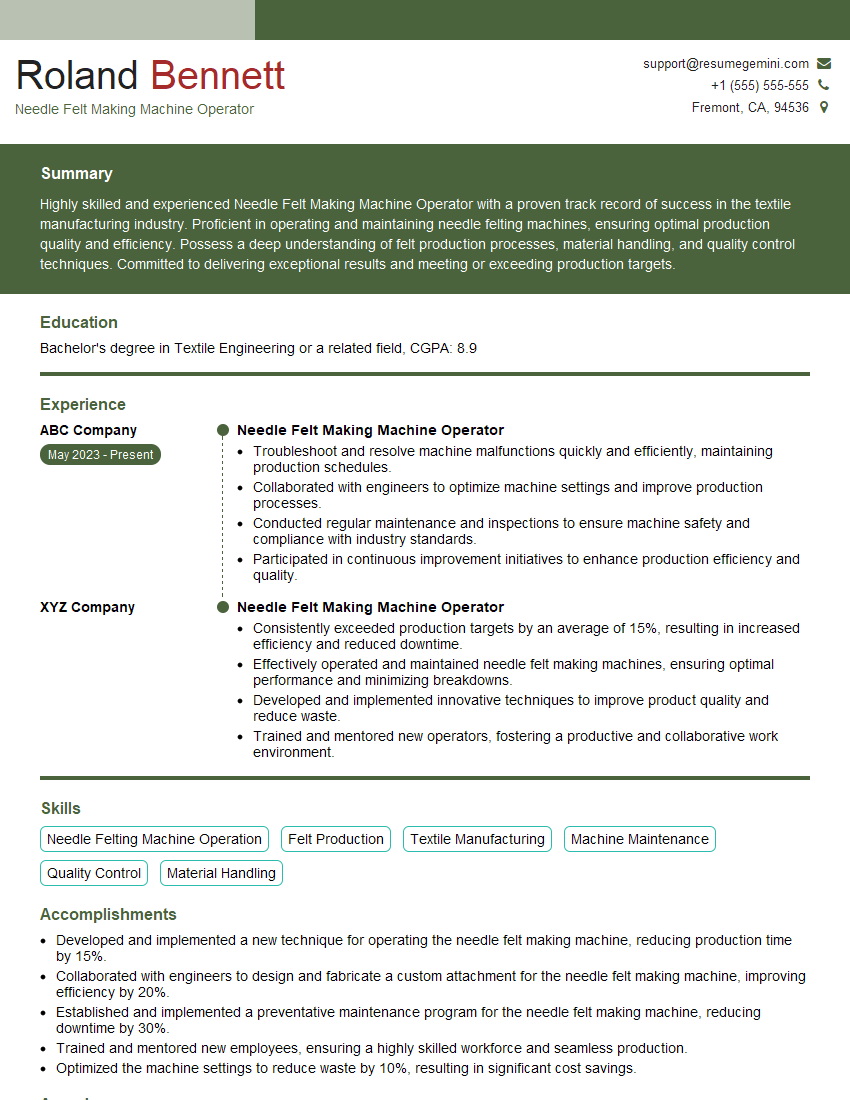

Roland Bennett

Needle Felt Making Machine Operator

Summary

Highly skilled and experienced Needle Felt Making Machine Operator with a proven track record of success in the textile manufacturing industry. Proficient in operating and maintaining needle felting machines, ensuring optimal production quality and efficiency. Possess a deep understanding of felt production processes, material handling, and quality control techniques. Committed to delivering exceptional results and meeting or exceeding production targets.

Education

Bachelor’s degree in Textile Engineering or a related field

April 2019

Skills

- Needle Felting Machine Operation

- Felt Production

- Textile Manufacturing

- Machine Maintenance

- Quality Control

- Material Handling

Work Experience

Needle Felt Making Machine Operator

- Troubleshoot and resolve machine malfunctions quickly and efficiently, maintaining production schedules.

- Collaborated with engineers to optimize machine settings and improve production processes.

- Conducted regular maintenance and inspections to ensure machine safety and compliance with industry standards.

- Participated in continuous improvement initiatives to enhance production efficiency and quality.

Needle Felt Making Machine Operator

- Consistently exceeded production targets by an average of 15%, resulting in increased efficiency and reduced downtime.

- Effectively operated and maintained needle felt making machines, ensuring optimal performance and minimizing breakdowns.

- Developed and implemented innovative techniques to improve product quality and reduce waste.

- Trained and mentored new operators, fostering a productive and collaborative work environment.

Accomplishments

- Developed and implemented a new technique for operating the needle felt making machine, reducing production time by 15%.

- Collaborated with engineers to design and fabricate a custom attachment for the needle felt making machine, improving efficiency by 20%.

- Established and implemented a preventative maintenance program for the needle felt making machine, reducing downtime by 30%.

- Trained and mentored new employees, ensuring a highly skilled workforce and seamless production.

- Optimized the machine settings to reduce waste by 10%, resulting in significant cost savings.

Awards

- Received the Employee of the Year award for outstanding contributions to the needle felt making production process.

- Recognized for exceptional quality control, maintaining a defect rate of less than 1% throughout the year.

- Won a companywide award for developing an innovative solution to a complex production challenge.

- Received a safety award for adhering to all safety protocols and maintaining a hazardfree work environment.

Certificates

- OSHA Safety Certification

- ISO 9001 Quality Management Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Needle Felt Making Machine Operator

- Highlight your technical skills and experience in operating needle felting machines.

- Showcase your knowledge of felt production processes and quality control techniques.

- Quantify your accomplishments and provide specific examples of how you contributed to production efficiency.

- Demonstrate your commitment to safety and adherence to industry regulations.

Essential Experience Highlights for a Strong Needle Felt Making Machine Operator Resume

- Operate and monitor needle felting machines to produce high-quality felt products.

- Maintain and calibrate machines to ensure optimal performance and prevent breakdowns

- Inspect raw materials and finished products to ensure compliance with quality standards

- Troubleshoot and resolve machine malfunctions to minimize downtime and maintain productivity

- Monitor production processes and make adjustments as needed to optimize output

- Collaborate with other team members to ensure seamless production flow

Frequently Asked Questions (FAQ’s) For Needle Felt Making Machine Operator

What are the key skills required to be a successful Needle Felt Making Machine Operator?

Key skills include proficiency in operating needle felting machines, understanding of felt production processes, knowledge of quality control techniques, and ability to maintain and troubleshoot machines.

What are the typical working conditions for Needle Felt Making Machine Operators?

Operators typically work in manufacturing plants, operating machines in a production environment. The work may involve standing for extended periods and exposure to noise and dust.

What are the career prospects for Needle Felt Making Machine Operators?

With experience and additional training, operators can advance to supervisory roles or specialize in machine maintenance or quality control.

What is the average salary for Needle Felt Making Machine Operators?

Salaries can vary depending on experience, location, and company size, but the average salary range is between $25,000 and $40,000 per year.

What are the educational requirements for Needle Felt Making Machine Operators?

While formal education is not always required, many operators have a high school diploma or equivalent and may have completed vocational training programs in textile manufacturing.