Are you a seasoned Nitric Acid Plant Operator seeking a new career path? Discover our professionally built Nitric Acid Plant Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

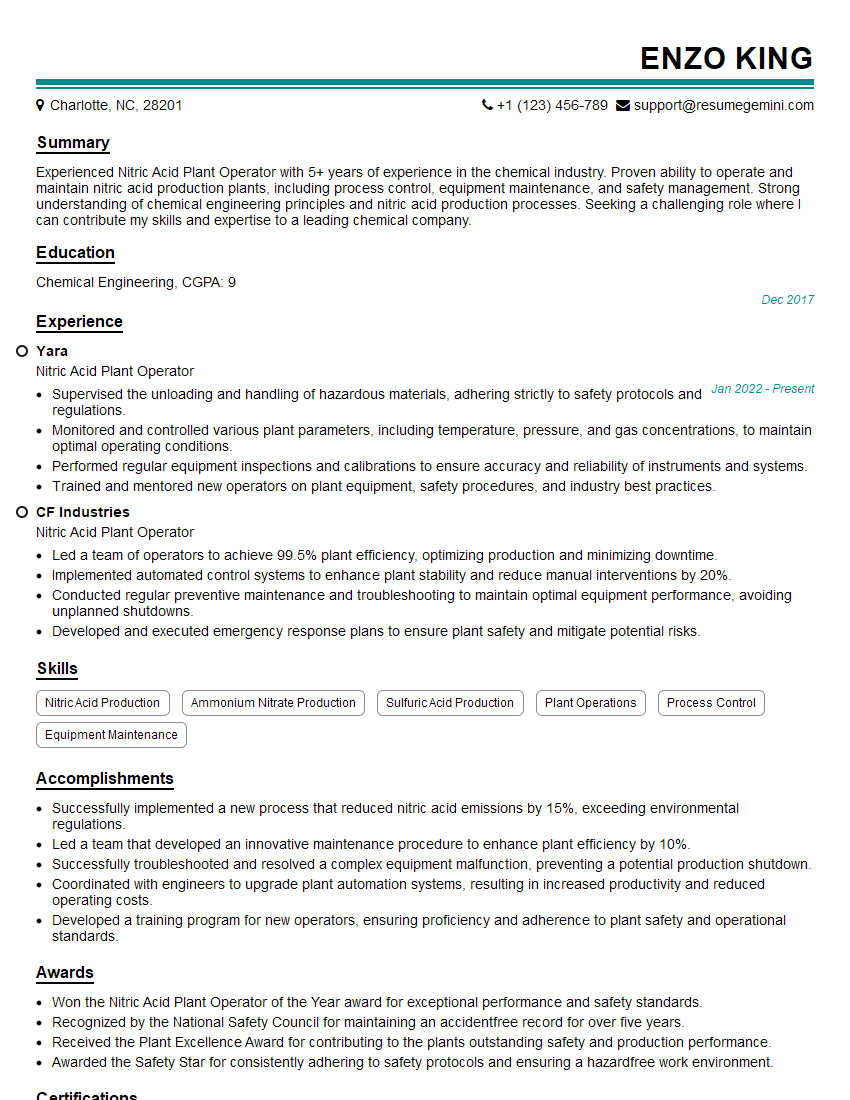

Enzo King

Nitric Acid Plant Operator

Summary

Experienced Nitric Acid Plant Operator with 5+ years of experience in the chemical industry. Proven ability to operate and maintain nitric acid production plants, including process control, equipment maintenance, and safety management. Strong understanding of chemical engineering principles and nitric acid production processes. Seeking a challenging role where I can contribute my skills and expertise to a leading chemical company.

Education

Chemical Engineering

December 2017

Skills

- Nitric Acid Production

- Ammonium Nitrate Production

- Sulfuric Acid Production

- Plant Operations

- Process Control

- Equipment Maintenance

Work Experience

Nitric Acid Plant Operator

- Supervised the unloading and handling of hazardous materials, adhering strictly to safety protocols and regulations.

- Monitored and controlled various plant parameters, including temperature, pressure, and gas concentrations, to maintain optimal operating conditions.

- Performed regular equipment inspections and calibrations to ensure accuracy and reliability of instruments and systems.

- Trained and mentored new operators on plant equipment, safety procedures, and industry best practices.

Nitric Acid Plant Operator

- Led a team of operators to achieve 99.5% plant efficiency, optimizing production and minimizing downtime.

- Implemented automated control systems to enhance plant stability and reduce manual interventions by 20%.

- Conducted regular preventive maintenance and troubleshooting to maintain optimal equipment performance, avoiding unplanned shutdowns.

- Developed and executed emergency response plans to ensure plant safety and mitigate potential risks.

Accomplishments

- Successfully implemented a new process that reduced nitric acid emissions by 15%, exceeding environmental regulations.

- Led a team that developed an innovative maintenance procedure to enhance plant efficiency by 10%.

- Successfully troubleshooted and resolved a complex equipment malfunction, preventing a potential production shutdown.

- Coordinated with engineers to upgrade plant automation systems, resulting in increased productivity and reduced operating costs.

- Developed a training program for new operators, ensuring proficiency and adherence to plant safety and operational standards.

Awards

- Won the Nitric Acid Plant Operator of the Year award for exceptional performance and safety standards.

- Recognized by the National Safety Council for maintaining an accidentfree record for over five years.

- Received the Plant Excellence Award for contributing to the plants outstanding safety and production performance.

- Awarded the Safety Star for consistently adhering to safety protocols and ensuring a hazardfree work environment.

Certificates

- Certified Nitric Acid Plant Operator (CNAPO)

- Certified Ammonium Nitrate Plant Operator (CANPO)

- Certified Sulfuric Acid Plant Operator (CSAPO)

- OSHA 30-Hour General Industry Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Nitric Acid Plant Operator

- Highlight your experience and skills in nitric acid production, including your understanding of the chemical processes involved.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on plant operations.

- Emphasize your commitment to safety and compliance, as these are critical aspects of nitric acid plant operations.

- Showcase your problem-solving abilities and ability to work independently and as part of a team.

- Tailor your resume to the specific requirements of each job application, highlighting the skills and experience that are most relevant to the role.

Essential Experience Highlights for a Strong Nitric Acid Plant Operator Resume

- Operate and monitor nitric acid production plants, ensuring efficient and safe operations.

- Control process parameters, including temperature, pressure, and flow rates, to optimize production.

- Perform routine maintenance and repairs on plant equipment, including pumps, compressors, and valves.

- Troubleshoot and resolve plant malfunctions, minimizing downtime and ensuring production efficiency.

- Adhere to all safety protocols and regulations to maintain a safe and compliant work environment.

- Monitor environmental emissions and implement measures to minimize impact.

- Maintain accurate records of plant operations and production data.

Frequently Asked Questions (FAQ’s) For Nitric Acid Plant Operator

What is the role of a Nitric Acid Plant Operator?

A Nitric Acid Plant Operator is responsible for the safe and efficient operation and maintenance of nitric acid production plants. They ensure that the plant operates within specified parameters, troubleshoot and resolve malfunctions, perform routine maintenance, and adhere to safety protocols.

What are the key skills required for a Nitric Acid Plant Operator?

Key skills for a Nitric Acid Plant Operator include knowledge of nitric acid production processes, process control, equipment maintenance, safety protocols, and environmental regulations. They should also have strong problem-solving abilities and be able to work independently and as part of a team.

What is the work environment of a Nitric Acid Plant Operator?

Nitric Acid Plant Operators typically work in industrial settings, such as chemical plants or fertilizer manufacturing facilities. The work environment can be hazardous, involving exposure to chemicals, noise, and potential safety risks. They must wear appropriate personal protective equipment and adhere to safety protocols to minimize risks.

What are the career prospects for a Nitric Acid Plant Operator?

Nitric Acid Plant Operators can advance their careers by gaining experience and developing their skills. They can move into supervisory or management roles, or specialize in areas such as process optimization, safety management, or environmental compliance. With additional education and training, they can also pursue roles in engineering or research.

What are the safety considerations for a Nitric Acid Plant Operator?

Nitric Acid Plant Operators must be aware of the potential hazards associated with working with nitric acid and other chemicals. They must wear appropriate personal protective equipment, such as respirators, gloves, and protective clothing. They must also be trained in emergency procedures and be able to respond quickly to accidents or spills.

What is the role of nitric acid in industry?

Nitric acid is a highly corrosive and reactive chemical used in various industrial processes. It is primarily used in the production of fertilizers, explosives, and dyes. It is also used in metalworking, electronics, and wastewater treatment.

What is the impact of nitric acid production on the environment?

Nitric acid production can release harmful emissions into the air and water, including nitrogen oxides and nitrous oxide. These emissions can contribute to air and water pollution, acid rain, and climate change. Nitric acid plants must implement measures to minimize emissions and comply with environmental regulations.

What are the emerging trends in nitric acid production?

Emerging trends in nitric acid production include the development of more energy-efficient and environmentally friendly technologies. This includes the use of renewable energy sources, such as solar and wind power, and the implementation of advanced process control systems to optimize production and reduce emissions.