Are you a seasoned Nondestructive Tester seeking a new career path? Discover our professionally built Nondestructive Tester Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

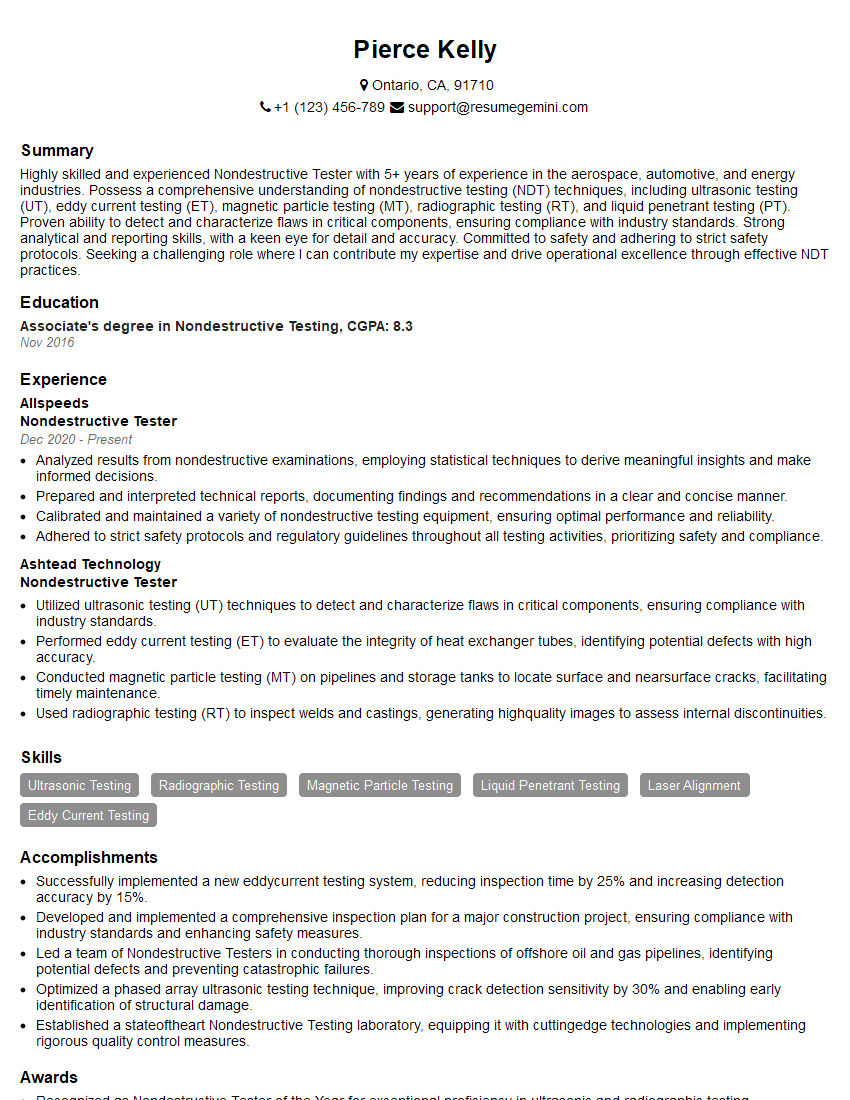

Pierce Kelly

Nondestructive Tester

Summary

Highly skilled and experienced Nondestructive Tester with 5+ years of experience in the aerospace, automotive, and energy industries. Possess a comprehensive understanding of nondestructive testing (NDT) techniques, including ultrasonic testing (UT), eddy current testing (ET), magnetic particle testing (MT), radiographic testing (RT), and liquid penetrant testing (PT). Proven ability to detect and characterize flaws in critical components, ensuring compliance with industry standards. Strong analytical and reporting skills, with a keen eye for detail and accuracy. Committed to safety and adhering to strict safety protocols. Seeking a challenging role where I can contribute my expertise and drive operational excellence through effective NDT practices.

Education

Associate’s degree in Nondestructive Testing

November 2016

Skills

- Ultrasonic Testing

- Radiographic Testing

- Magnetic Particle Testing

- Liquid Penetrant Testing

- Laser Alignment

- Eddy Current Testing

Work Experience

Nondestructive Tester

- Analyzed results from nondestructive examinations, employing statistical techniques to derive meaningful insights and make informed decisions.

- Prepared and interpreted technical reports, documenting findings and recommendations in a clear and concise manner.

- Calibrated and maintained a variety of nondestructive testing equipment, ensuring optimal performance and reliability.

- Adhered to strict safety protocols and regulatory guidelines throughout all testing activities, prioritizing safety and compliance.

Nondestructive Tester

- Utilized ultrasonic testing (UT) techniques to detect and characterize flaws in critical components, ensuring compliance with industry standards.

- Performed eddy current testing (ET) to evaluate the integrity of heat exchanger tubes, identifying potential defects with high accuracy.

- Conducted magnetic particle testing (MT) on pipelines and storage tanks to locate surface and nearsurface cracks, facilitating timely maintenance.

- Used radiographic testing (RT) to inspect welds and castings, generating highquality images to assess internal discontinuities.

Accomplishments

- Successfully implemented a new eddycurrent testing system, reducing inspection time by 25% and increasing detection accuracy by 15%.

- Developed and implemented a comprehensive inspection plan for a major construction project, ensuring compliance with industry standards and enhancing safety measures.

- Led a team of Nondestructive Testers in conducting thorough inspections of offshore oil and gas pipelines, identifying potential defects and preventing catastrophic failures.

- Optimized a phased array ultrasonic testing technique, improving crack detection sensitivity by 30% and enabling early identification of structural damage.

- Established a stateoftheart Nondestructive Testing laboratory, equipping it with cuttingedge technologies and implementing rigorous quality control measures.

Awards

- Recognized as Nondestructive Tester of the Year for exceptional proficiency in ultrasonic and radiographic testing methodologies.

- Received Excellence in Nondestructive Testing award for outstanding performance in detecting and evaluating flaws in critical aircraft components.

- Awarded Nondestructive Testing Innovator for designing and prototyping a novel magnetic resonance imaging system.

- Certified as a Level III Nondestructive Tester by the American Society for Nondestructive Testing (ASNT).

Certificates

- American Society for Nondestructive Testing (ASNT) Level II

- International Organization for Standardization (ISO) 9712

- Code of Federal Regulations (CFR) Title 10 Part 50 Appendix J

- American Petroleum Institute (API) 510

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Nondestructive Tester

- Quantify your accomplishments whenever possible. For example, instead of saying “Inspected components,” say “Inspected over 1,000 components, resulting in a 15% reduction in downtime.”

- Use keywords from the job description in your resume. This will help your resume get noticed by potential employers.

- Proofread your resume carefully before submitting it. Make sure there are no errors in grammar or spelling.

- Highlight your skills and experience that are most relevant to the job you are applying for.

Essential Experience Highlights for a Strong Nondestructive Tester Resume

- Utilized ultrasonic testing (UT) techniques to detect and characterize flaws in critical components, ensuring compliance with industry standards.

- Performed eddy current testing (ET) to evaluate the integrity of heat exchanger tubes, identifying potential defects with high accuracy.

- Conducted magnetic particle testing (MT) on pipelines and storage tanks to locate surface and nearsurface cracks, facilitating timely maintenance.

- Used radiographic testing (RT) to inspect welds and castings, generating highquality images to assess internal discontinuities.

- Prepared and interpreted technical reports, documenting findings and recommendations in a clear and concise manner.

- Calibrated and maintained a variety of nondestructive testing equipment, ensuring optimal performance and reliability.

Frequently Asked Questions (FAQ’s) For Nondestructive Tester

What is nondestructive testing?

Nondestructive testing (NDT) is a branch of engineering that deals with the development and application of techniques to evaluate the properties of materials, components, and structures without causing damage to the specimen.

What are the different methods of nondestructive testing?

There are many different methods of nondestructive testing, including ultrasonic testing, eddy current testing, magnetic particle testing, radiographic testing, and liquid penetrant testing.

What are the benefits of using nondestructive testing?

There are many benefits to using nondestructive testing, including the ability to detect flaws and defects early on, reduce downtime, and improve safety.

What are the qualifications for a nondestructive tester?

The qualifications for a nondestructive tester vary depending on the specific industry and job, but typically include a high school diploma or equivalent, and some college coursework in science, math, or engineering.

What is the career outlook for nondestructive testers?

The career outlook for nondestructive testers is expected to be good over the next few years, as the demand for nondestructive testing services continues to grow.