Are you a seasoned Notcher seeking a new career path? Discover our professionally built Notcher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

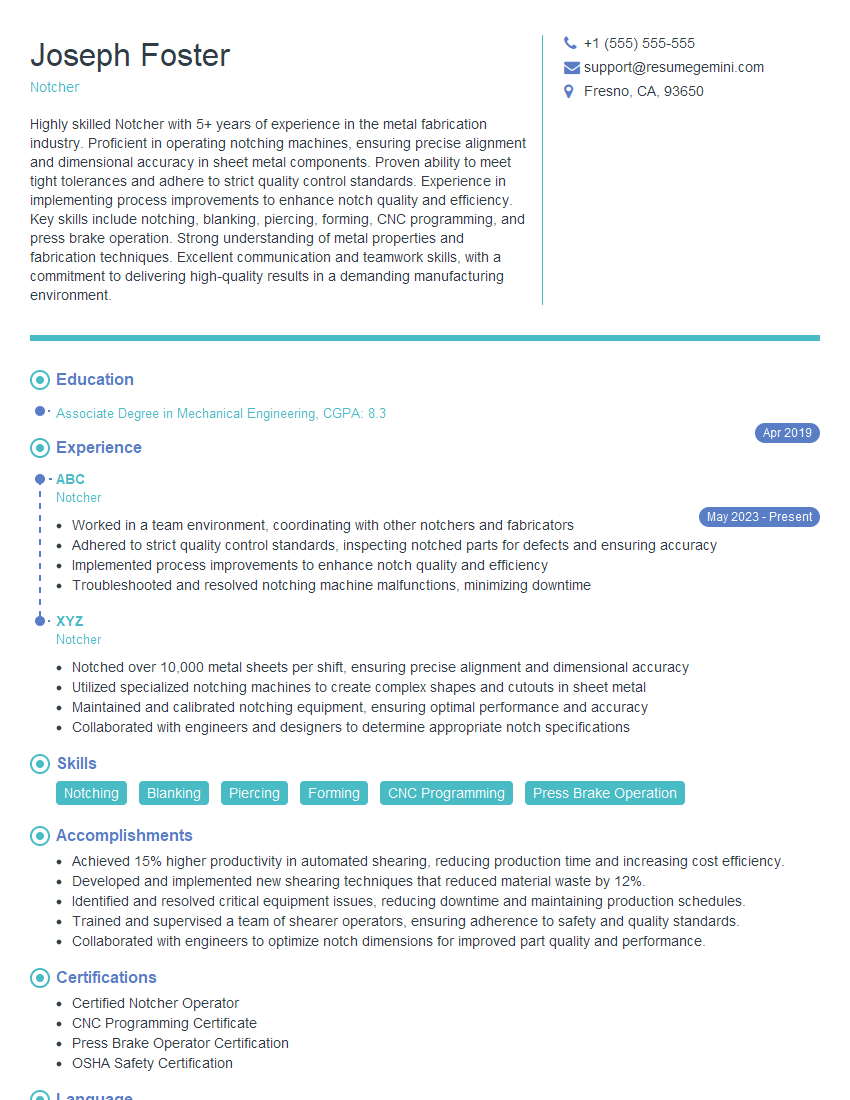

Joseph Foster

Notcher

Summary

Highly skilled Notcher with 5+ years of experience in the metal fabrication industry. Proficient in operating notching machines, ensuring precise alignment and dimensional accuracy in sheet metal components. Proven ability to meet tight tolerances and adhere to strict quality control standards. Experience in implementing process improvements to enhance notch quality and efficiency.

Key skills include notching, blanking, piercing, forming, CNC programming, and press brake operation. Strong understanding of metal properties and fabrication techniques. Excellent communication and teamwork skills, with a commitment to delivering high-quality results in a demanding manufacturing environment.

Education

Associate Degree in Mechanical Engineering

April 2019

Skills

- Notching

- Blanking

- Piercing

- Forming

- CNC Programming

- Press Brake Operation

Work Experience

Notcher

- Worked in a team environment, coordinating with other notchers and fabricators

- Adhered to strict quality control standards, inspecting notched parts for defects and ensuring accuracy

- Implemented process improvements to enhance notch quality and efficiency

- Troubleshooted and resolved notching machine malfunctions, minimizing downtime

Notcher

- Notched over 10,000 metal sheets per shift, ensuring precise alignment and dimensional accuracy

- Utilized specialized notching machines to create complex shapes and cutouts in sheet metal

- Maintained and calibrated notching equipment, ensuring optimal performance and accuracy

- Collaborated with engineers and designers to determine appropriate notch specifications

Accomplishments

- Achieved 15% higher productivity in automated shearing, reducing production time and increasing cost efficiency.

- Developed and implemented new shearing techniques that reduced material waste by 12%.

- Identified and resolved critical equipment issues, reducing downtime and maintaining production schedules.

- Trained and supervised a team of shearer operators, ensuring adherence to safety and quality standards.

- Collaborated with engineers to optimize notch dimensions for improved part quality and performance.

Certificates

- Certified Notcher Operator

- CNC Programming Certificate

- Press Brake Operator Certification

- OSHA Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Notcher

- Highlight your experience and skills in notching, blanking, piercing, forming, and other relevant fabrication techniques.

- Quantify your accomplishments by providing specific metrics and results, such as the number of sheets notched per shift or the percentage of parts that met quality standards.

- Demonstrate your knowledge of metal properties and fabrication techniques by describing your experience in working with different types of metals and using various fabrication equipment.

- Emphasize your attention to detail, precision, and commitment to quality.

- Showcase your teamwork skills and ability to collaborate effectively in a fast-paced manufacturing environment.

Essential Experience Highlights for a Strong Notcher Resume

- Notched over 10,000 metal sheets per shift, ensuring precise alignment and dimensional accuracy

- Utilized specialized notching machines to create complex shapes and cutouts in sheet metal

- Maintained and calibrated notching equipment, ensuring optimal performance and accuracy

- Collaborated with engineers and designers to determine appropriate notch specifications

- Worked in a team environment, coordinating with other notchers and fabricators

- Adhered to strict quality control standards, inspecting notched parts for defects and ensuring accuracy

- Implemented process improvements to enhance notch quality and efficiency

Frequently Asked Questions (FAQ’s) For Notcher

What is a Notcher?

A Notcher is a skilled technician responsible for operating notching machines to create precise cuts and shapes in sheet metal. They ensure dimensional accuracy, maintain equipment, and adhere to quality control standards in the metal fabrication industry.

What are the key responsibilities of a Notcher?

Notchers are responsible for operating notching machines, maintaining equipment, ensuring dimensional accuracy, collaborating with engineers and designers, working in a team environment, adhering to quality control standards, and implementing process improvements.

What skills are required to be a successful Notcher?

Successful Notchers possess skills in notching, blanking, piercing, forming, CNC programming, and press brake operation. They have a strong understanding of metal properties and fabrication techniques, as well as excellent communication and teamwork skills.

What is the work environment of a Notcher like?

Notchers typically work in manufacturing environments, operating notching machines and working with metal sheets. They may work independently or as part of a team, and the job requires attention to detail, precision, and adherence to safety regulations.

What are the career prospects for Notchers?

Notchers with experience and expertise can advance to supervisory or management roles within the metal fabrication industry. They may also specialize in specific areas, such as CNC programming or quality control.

How can I become a Notcher?

To become a Notcher, individuals typically complete an associate degree or certificate program in mechanical engineering or a related field. They may also gain experience through apprenticeships or on-the-job training.

What is the average salary for Notchers?

The average salary for Notchers varies depending on experience, location, and industry. According to Indeed, the average salary for a Notcher in the United States is around $25 per hour.