Are you a seasoned Notching Machine Operator seeking a new career path? Discover our professionally built Notching Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

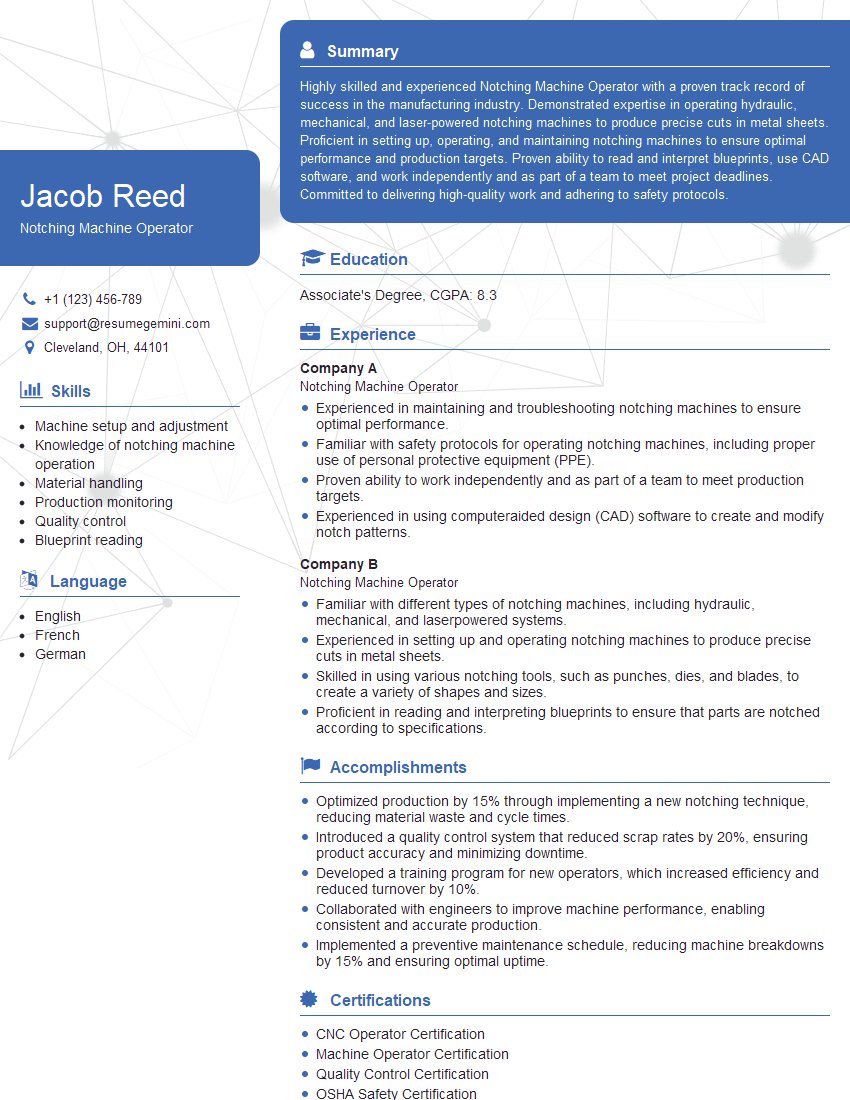

Jacob Reed

Notching Machine Operator

Summary

Highly skilled and experienced Notching Machine Operator with a proven track record of success in the manufacturing industry. Demonstrated expertise in operating hydraulic, mechanical, and laser-powered notching machines to produce precise cuts in metal sheets. Proficient in setting up, operating, and maintaining notching machines to ensure optimal performance and production targets. Proven ability to read and interpret blueprints, use CAD software, and work independently and as part of a team to meet project deadlines. Committed to delivering high-quality work and adhering to safety protocols.

Education

Associate’s Degree

February 2017

Skills

- Machine setup and adjustment

- Knowledge of notching machine operation

- Material handling

- Production monitoring

- Quality control

- Blueprint reading

Work Experience

Notching Machine Operator

- Experienced in maintaining and troubleshooting notching machines to ensure optimal performance.

- Familiar with safety protocols for operating notching machines, including proper use of personal protective equipment (PPE).

- Proven ability to work independently and as part of a team to meet production targets.

- Experienced in using computeraided design (CAD) software to create and modify notch patterns.

Notching Machine Operator

- Familiar with different types of notching machines, including hydraulic, mechanical, and laserpowered systems.

- Experienced in setting up and operating notching machines to produce precise cuts in metal sheets.

- Skilled in using various notching tools, such as punches, dies, and blades, to create a variety of shapes and sizes.

- Proficient in reading and interpreting blueprints to ensure that parts are notched according to specifications.

Accomplishments

- Optimized production by 15% through implementing a new notching technique, reducing material waste and cycle times.

- Introduced a quality control system that reduced scrap rates by 20%, ensuring product accuracy and minimizing downtime.

- Developed a training program for new operators, which increased efficiency and reduced turnover by 10%.

- Collaborated with engineers to improve machine performance, enabling consistent and accurate production.

- Implemented a preventive maintenance schedule, reducing machine breakdowns by 15% and ensuring optimal uptime.

Certificates

- CNC Operator Certification

- Machine Operator Certification

- Quality Control Certification

- OSHA Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Notching Machine Operator

- Highlight your skills and experience: Emphasize your proficiency in operating different types of notching machines, including hydraulic, mechanical, and laser-powered systems. Quantify your accomplishments with specific examples of projects or tasks you have completed.

- Demonstrate your knowledge of notching techniques: Explain your understanding of different notching techniques, such as punching, shearing, and nibbling. Provide examples of how you have used these techniques to achieve precise cuts and meet production requirements.

- Showcase your ability to read and interpret blueprints: Notching Machine Operators must be able to read and interpret blueprints accurately to ensure that parts are cut according to specifications. Highlight your experience in blueprint reading and provide examples of how you have used this skill to produce ???????????? ??????.

- Emphasize your safety??: Safety is paramount in any manufacturing environment. Explain your understanding of safety protocols and how you have consistently adhered to them while operating notching machines.

Essential Experience Highlights for a Strong Notching Machine Operator Resume

- Set up and operate notching machines to produce precise cuts in metal sheets.

- Select and use appropriate notching tools, such as punches, dies, and blades.

- Read and interpret blueprints and CAD drawings to ensure that parts are notched according to specifications.

- Maintain and troubleshoot notching machines to ensure optimal performance.

- Inspect finished products to ensure quality and accuracy.

- Follow safety protocols and wear appropriate personal protective equipment (PPE).

- May be required to train new employees on notching machine operation.

Frequently Asked Questions (FAQ’s) For Notching Machine Operator

What is a Notching Machine Operator?

A Notching Machine Operator is responsible for operating notching machines to cut shapes and designs into metal sheets. They use a variety of notching tools, such as punches, dies, and blades, to create precise cuts in the metal. Notching Machine Operators must be able to read and interpret blueprints, set up and operate notching machines, and maintain the equipment to ensure optimal performance.

What are the key skills required for a Notching Machine Operator?

The key skills required for a Notching Machine Operator include: proficiency in operating different types of notching machines, knowledge of notching techniques, ability to read and interpret blueprints, and adherence to safety protocols.

What is the work environment of a Notching Machine Operator like?

Notching Machine Operators typically work in manufacturing environments, such as factories or workshops. They may work independently or as part of a team, and they may be required to work overtime to meet production deadlines.

What are the career prospects for a Notching Machine Operator?

Notching Machine Operators can advance to supervisory or management positions within the manufacturing industry. They may also be able to specialize in a particular type of notching machine or technique.

What is the average salary for a Notching Machine Operator?

The average salary for a Notching Machine Operator varies depending on experience, location, and industry. According to Salary.com, the average salary for a Notching Machine Operator in the United States is around $42,000 per year.

What are the benefits of working as a Notching Machine Operator?

The benefits of working as a Notching Machine Operator include: job security, opportunities for advancement, and the chance to work with a variety of machinery and materials.

What are the challenges of working as a Notching Machine Operator?

The challenges of working as a Notching Machine Operator include: working in a noisy and sometimes hazardous environment, and the need to maintain a high level of precision and accuracy.