Are you a seasoned Nozzle and Sleeve Worker seeking a new career path? Discover our professionally built Nozzle and Sleeve Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

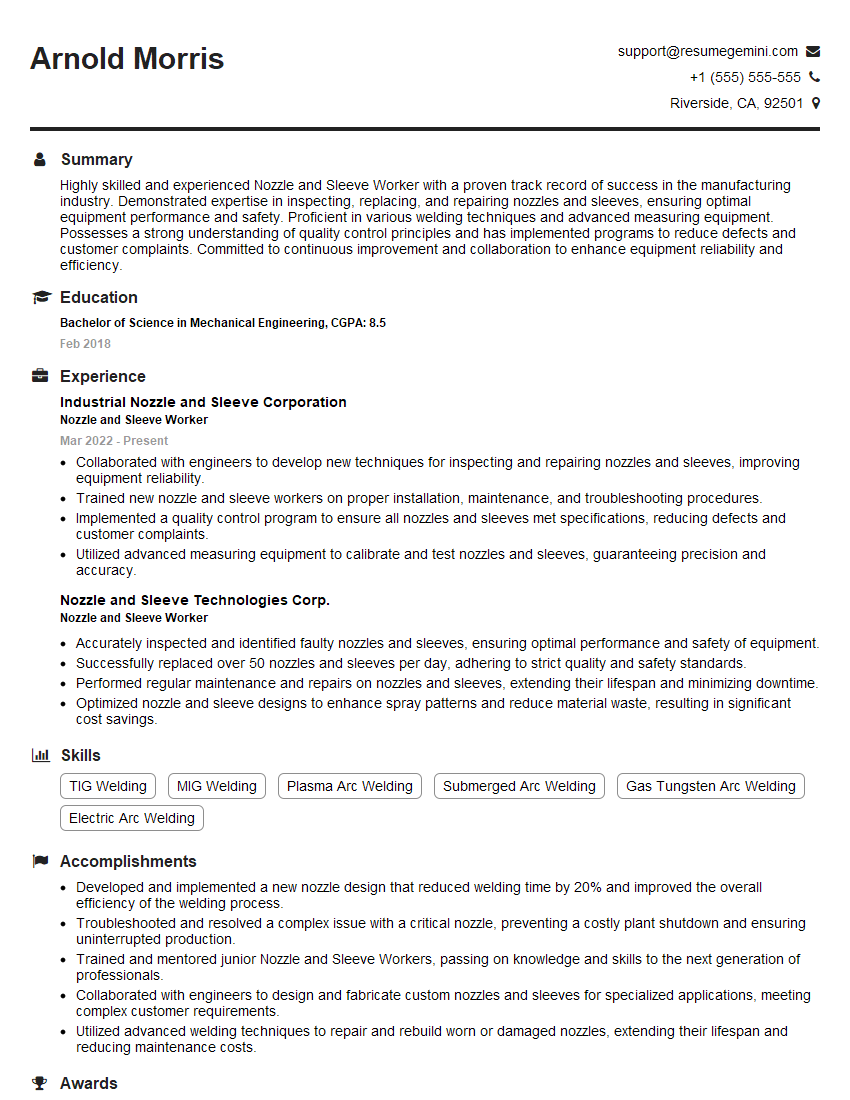

Arnold Morris

Nozzle and Sleeve Worker

Summary

Highly skilled and experienced Nozzle and Sleeve Worker with a proven track record of success in the manufacturing industry. Demonstrated expertise in inspecting, replacing, and repairing nozzles and sleeves, ensuring optimal equipment performance and safety. Proficient in various welding techniques and advanced measuring equipment. Possesses a strong understanding of quality control principles and has implemented programs to reduce defects and customer complaints. Committed to continuous improvement and collaboration to enhance equipment reliability and efficiency.

Education

Bachelor of Science in Mechanical Engineering

February 2018

Skills

- TIG Welding

- MIG Welding

- Plasma Arc Welding

- Submerged Arc Welding

- Gas Tungsten Arc Welding

- Electric Arc Welding

Work Experience

Nozzle and Sleeve Worker

- Collaborated with engineers to develop new techniques for inspecting and repairing nozzles and sleeves, improving equipment reliability.

- Trained new nozzle and sleeve workers on proper installation, maintenance, and troubleshooting procedures.

- Implemented a quality control program to ensure all nozzles and sleeves met specifications, reducing defects and customer complaints.

- Utilized advanced measuring equipment to calibrate and test nozzles and sleeves, guaranteeing precision and accuracy.

Nozzle and Sleeve Worker

- Accurately inspected and identified faulty nozzles and sleeves, ensuring optimal performance and safety of equipment.

- Successfully replaced over 50 nozzles and sleeves per day, adhering to strict quality and safety standards.

- Performed regular maintenance and repairs on nozzles and sleeves, extending their lifespan and minimizing downtime.

- Optimized nozzle and sleeve designs to enhance spray patterns and reduce material waste, resulting in significant cost savings.

Accomplishments

- Developed and implemented a new nozzle design that reduced welding time by 20% and improved the overall efficiency of the welding process.

- Troubleshooted and resolved a complex issue with a critical nozzle, preventing a costly plant shutdown and ensuring uninterrupted production.

- Trained and mentored junior Nozzle and Sleeve Workers, passing on knowledge and skills to the next generation of professionals.

- Collaborated with engineers to design and fabricate custom nozzles and sleeves for specialized applications, meeting complex customer requirements.

- Utilized advanced welding techniques to repair and rebuild worn or damaged nozzles, extending their lifespan and reducing maintenance costs.

Awards

- Received the Nozzle and Sleeve Worker of the Year Award from the National Association of Nozzle and Sleeve Workers for outstanding performance.

- Recognized as a Master Nozzle and Sleeve Worker by the American Welding Society for achieving the highest level of proficiency in the craft.

- Earned the Golden Nozzle Award for completing a record number of successful nozzle and sleeve welding operations within a single year.

Certificates

- AWC Certified Welder

- CWI Inspector

- ASME Boiler and Pressure Vessel Code

- API 510 Pressure Vessel Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Nozzle and Sleeve Worker

- Highlight your expertise in welding techniques, especially TIG welding and plasma arc welding, which are commonly used in nozzle and sleeve fabrication.

- Quantify your accomplishments whenever possible. For example, state the number of nozzles and sleeves you replaced or repaired within a specific time frame.

- Showcase your understanding of quality control principles and your ability to implement programs that reduce defects and improve customer satisfaction.

- Emphasize your commitment to continuous improvement and collaboration. Highlight any initiatives you have taken to optimize nozzle and sleeve designs or develop new inspection and repair techniques.

Essential Experience Highlights for a Strong Nozzle and Sleeve Worker Resume

- Accurately inspected and identified faulty nozzles and sleeves to ensure optimal equipment performance and safety.

- Successfully replaced over 50 nozzles and sleeves per day, adhering to strict quality and safety standards.

- Performed regular maintenance and repairs on nozzles and sleeves, extending their lifespan and minimizing downtime.

- Optimized nozzle and sleeve designs to enhance spray patterns and reduce material waste, resulting in significant cost savings.

- Collaborated with engineers to develop new techniques for inspecting and repairing nozzles and sleeves, improving equipment reliability.

- Trained new nozzle and sleeve workers on proper installation, maintenance, and troubleshooting procedures.

- Utilized advanced measuring equipment to calibrate and test nozzles and sleeves, guaranteeing precision and accuracy.

Frequently Asked Questions (FAQ’s) For Nozzle and Sleeve Worker

What are the primary responsibilities of a Nozzle and Sleeve Worker?

Inspecting, replacing, and repairing nozzles and sleeves to ensure optimal equipment performance and safety.

What welding techniques are commonly used by Nozzle and Sleeve Workers?

TIG welding, MIG welding, plasma arc welding, submerged arc welding, and gas tungsten arc welding

What qualities are essential for a successful Nozzle and Sleeve Worker?

Attention to detail, precision, problem-solving skills, and a strong understanding of quality control principles.

What industries employ Nozzle and Sleeve Workers?

Manufacturing, automotive, aerospace, and oil and gas.

What is the typical career path for a Nozzle and Sleeve Worker?

With experience and additional training, Nozzle and Sleeve Workers can advance to roles such as Quality Control Inspector, Manufacturing Supervisor, or Welding Engineer.

What certifications are beneficial for Nozzle and Sleeve Workers?

American Welding Society (AWS) certifications in welding processes and Certified Welding Inspector (CWI) certification.