Are you a seasoned Numerical Control Milling Machine Operator seeking a new career path? Discover our professionally built Numerical Control Milling Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

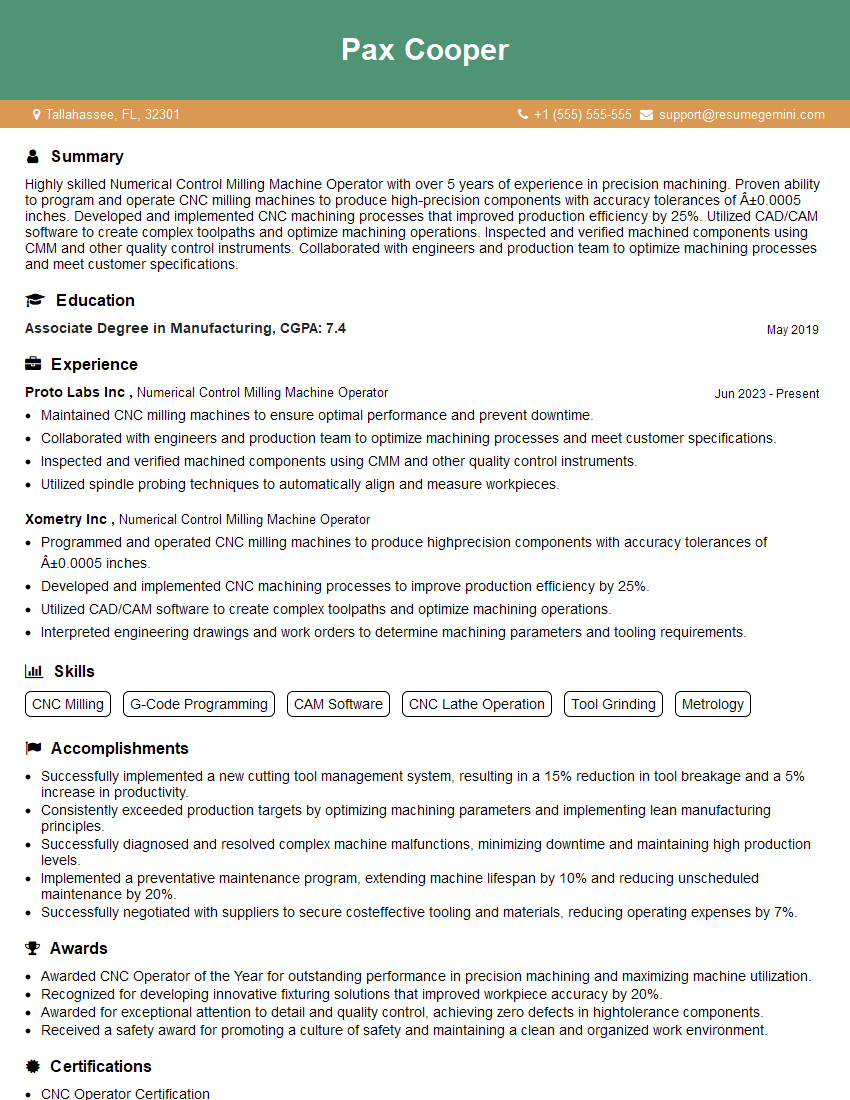

Pax Cooper

Numerical Control Milling Machine Operator

Summary

Highly skilled Numerical Control Milling Machine Operator with over 5 years of experience in precision machining. Proven ability to program and operate CNC milling machines to produce high-precision components with accuracy tolerances of ±0.0005 inches. Developed and implemented CNC machining processes that improved production efficiency by 25%. Utilized CAD/CAM software to create complex toolpaths and optimize machining operations. Inspected and verified machined components using CMM and other quality control instruments. Collaborated with engineers and production team to optimize machining processes and meet customer specifications.

Education

Associate Degree in Manufacturing

May 2019

Skills

- CNC Milling

- G-Code Programming

- CAM Software

- CNC Lathe Operation

- Tool Grinding

- Metrology

Work Experience

Numerical Control Milling Machine Operator

- Maintained CNC milling machines to ensure optimal performance and prevent downtime.

- Collaborated with engineers and production team to optimize machining processes and meet customer specifications.

- Inspected and verified machined components using CMM and other quality control instruments.

- Utilized spindle probing techniques to automatically align and measure workpieces.

Numerical Control Milling Machine Operator

- Programmed and operated CNC milling machines to produce highprecision components with accuracy tolerances of ±0.0005 inches.

- Developed and implemented CNC machining processes to improve production efficiency by 25%.

- Utilized CAD/CAM software to create complex toolpaths and optimize machining operations.

- Interpreted engineering drawings and work orders to determine machining parameters and tooling requirements.

Accomplishments

- Successfully implemented a new cutting tool management system, resulting in a 15% reduction in tool breakage and a 5% increase in productivity.

- Consistently exceeded production targets by optimizing machining parameters and implementing lean manufacturing principles.

- Successfully diagnosed and resolved complex machine malfunctions, minimizing downtime and maintaining high production levels.

- Implemented a preventative maintenance program, extending machine lifespan by 10% and reducing unscheduled maintenance by 20%.

- Successfully negotiated with suppliers to secure costeffective tooling and materials, reducing operating expenses by 7%.

Awards

- Awarded CNC Operator of the Year for outstanding performance in precision machining and maximizing machine utilization.

- Recognized for developing innovative fixturing solutions that improved workpiece accuracy by 20%.

- Awarded for exceptional attention to detail and quality control, achieving zero defects in hightolerance components.

- Received a safety award for promoting a culture of safety and maintaining a clean and organized work environment.

Certificates

- CNC Operator Certification

- G-Code Programmer Certification

- CAM Software Certification

- Metrology Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Numerical Control Milling Machine Operator

- Highlight your experience and skills in CNC milling, G-Code programming, and CAM software.

- Showcase your ability to improve production efficiency and meet customer specifications.

- Provide examples of your work that demonstrate your precision and accuracy.

- Tailor your resume to the specific requirements of each job you apply for.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Numerical Control Milling Machine Operator Resume

- Program and operate CNC milling machines to produce high-precision components.

- Develop and implement CNC machining processes to improve production efficiency.

- Utilize CAD/CAM software to create complex toolpaths and optimize machining operations.

- Interpret engineering drawings and work orders to determine machining parameters and tooling requirements.

- Maintain CNC milling machines to ensure optimal performance and prevent downtime.

- Collaborate with engineers and production team to optimize machining processes and meet customer specifications.

- Inspect and verify machined components using CMM and other quality control instruments.

Frequently Asked Questions (FAQ’s) For Numerical Control Milling Machine Operator

What is the role of a Numerical Control Milling Machine Operator?

Numerical Control Milling Machine Operators are responsible for programming and operating CNC milling machines to produce high-precision components. They use CAD/CAM software to create toolpaths and optimize machining operations, and they inspect and verify machined components to ensure they meet customer specifications.

What are the qualifications for a Numerical Control Milling Machine Operator?

Most Numerical Control Milling Machine Operators have an associate degree in manufacturing or a related field, and they have experience in CNC programming and machining. They must also be able to read and interpret engineering drawings and work orders.

What is the job outlook for Numerical Control Milling Machine Operators?

The job outlook for Numerical Control Milling Machine Operators is expected to be good over the next few years. The demand for precision-machined components is growing, and CNC milling machines are used to produce a wide range of products, from medical devices to aerospace components.

What are the benefits of working as a Numerical Control Milling Machine Operator?

Numerical Control Milling Machine Operators can earn a good salary and benefits package. They also have the opportunity to work with cutting-edge technology and produce high-precision components that are used in a variety of products.

What are the challenges of working as a Numerical Control Milling Machine Operator?

Numerical Control Milling Machine Operators can face challenges such as working with hazardous materials, working in a noisy environment, and working long hours.