Are you a seasoned Oil Spraying Machine Operator seeking a new career path? Discover our professionally built Oil Spraying Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

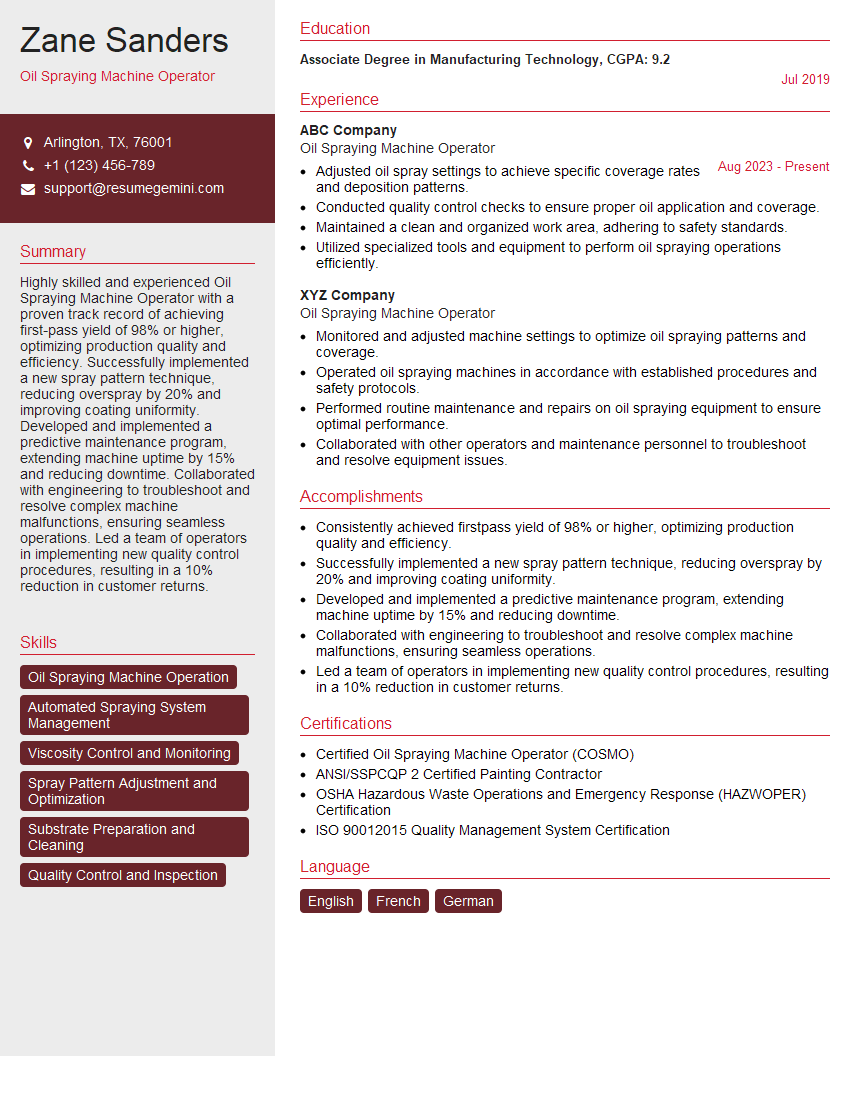

Zane Sanders

Oil Spraying Machine Operator

Summary

Highly skilled and experienced Oil Spraying Machine Operator with a proven track record of achieving first-pass yield of 98% or higher, optimizing production quality and efficiency. Successfully implemented a new spray pattern technique, reducing overspray by 20% and improving coating uniformity. Developed and implemented a predictive maintenance program, extending machine uptime by 15% and reducing downtime. Collaborated with engineering to troubleshoot and resolve complex machine malfunctions, ensuring seamless operations. Led a team of operators in implementing new quality control procedures, resulting in a 10% reduction in customer returns.

Education

Associate Degree in Manufacturing Technology

July 2019

Skills

- Oil Spraying Machine Operation

- Automated Spraying System Management

- Viscosity Control and Monitoring

- Spray Pattern Adjustment and Optimization

- Substrate Preparation and Cleaning

- Quality Control and Inspection

Work Experience

Oil Spraying Machine Operator

- Adjusted oil spray settings to achieve specific coverage rates and deposition patterns.

- Conducted quality control checks to ensure proper oil application and coverage.

- Maintained a clean and organized work area, adhering to safety standards.

- Utilized specialized tools and equipment to perform oil spraying operations efficiently.

Oil Spraying Machine Operator

- Monitored and adjusted machine settings to optimize oil spraying patterns and coverage.

- Operated oil spraying machines in accordance with established procedures and safety protocols.

- Performed routine maintenance and repairs on oil spraying equipment to ensure optimal performance.

- Collaborated with other operators and maintenance personnel to troubleshoot and resolve equipment issues.

Accomplishments

- Consistently achieved firstpass yield of 98% or higher, optimizing production quality and efficiency.

- Successfully implemented a new spray pattern technique, reducing overspray by 20% and improving coating uniformity.

- Developed and implemented a predictive maintenance program, extending machine uptime by 15% and reducing downtime.

- Collaborated with engineering to troubleshoot and resolve complex machine malfunctions, ensuring seamless operations.

- Led a team of operators in implementing new quality control procedures, resulting in a 10% reduction in customer returns.

Certificates

- Certified Oil Spraying Machine Operator (COSMO)

- ANSI/SSPCQP 2 Certified Painting Contractor

- OSHA Hazardous Waste Operations and Emergency Response (HAZWOPER) Certification

- ISO 90012015 Quality Management System Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Oil Spraying Machine Operator

- Highlight your experience and skills in operating oil spraying machines, including specific techniques and technologies.

- Quantify your accomplishments whenever possible, using metrics such as first-pass yield, overspray reduction, or downtime reduction.

- Demonstrate your understanding of coating materials, substrate preparation, and quality control procedures.

- Showcase your ability to work independently and as part of a team, and your commitment to safety and continuous improvement.

Essential Experience Highlights for a Strong Oil Spraying Machine Operator Resume

- Operate and maintain oil spraying machines to apply coatings and lubricants to various surfaces.

- Monitor and control machine settings, including viscosity, pressure, and spray pattern, to ensure optimal coating quality.

- Prepare and clean substrates prior to spraying to ensure proper adhesion and coating performance.

- Inspect coated surfaces to ensure they meet quality standards and specifications.

- Troubleshoot and resolve machine malfunctions to minimize downtime and ensure efficient production.

- Maintain a clean and organized work area, following established safety protocols.

- Collaborate with other operators and supervisors to optimize production processes and improve overall efficiency.

Frequently Asked Questions (FAQ’s) For Oil Spraying Machine Operator

What are the key skills and qualifications required to be an Oil Spraying Machine Operator?

The key skills and qualifications required to be an Oil Spraying Machine Operator include:

- Experience operating and maintaining oil spraying machines

- Knowledge of coating materials and substrate preparation

- Understanding of quality control procedures

- Ability to troubleshoot and resolve machine malfunctions

- Strong attention to detail and commitment to safety

What are the career advancement opportunities for Oil Spraying Machine Operators?

Oil Spraying Machine Operators can advance their careers by developing expertise in specialized coating techniques or by moving into supervisory roles. With additional training and experience, they can also become Quality Control Technicians or Production Managers.

What is the average salary for an Oil Spraying Machine Operator?

The average salary for an Oil Spraying Machine Operator varies depending on experience, location, and industry. According to Indeed.com, the average salary for an Oil Spraying Machine Operator in the United States is around $20 per hour.

What are the working conditions like for Oil Spraying Machine Operators?

Oil Spraying Machine Operators typically work in manufacturing or industrial settings. They may be exposed to chemicals and fumes, and they may have to work in hot or noisy environments. They may also have to work overtime or on weekends to meet production deadlines.

What are the safety precautions that Oil Spraying Machine Operators must follow?

Oil Spraying Machine Operators must follow a number of safety precautions to protect themselves from hazards such as chemical exposure, falls, and machinery accidents. These precautions include wearing appropriate personal protective equipment, following lockout/tagout procedures, and being aware of potential hazards in the work area.