Are you a seasoned Operations Plant Attendant seeking a new career path? Discover our professionally built Operations Plant Attendant Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

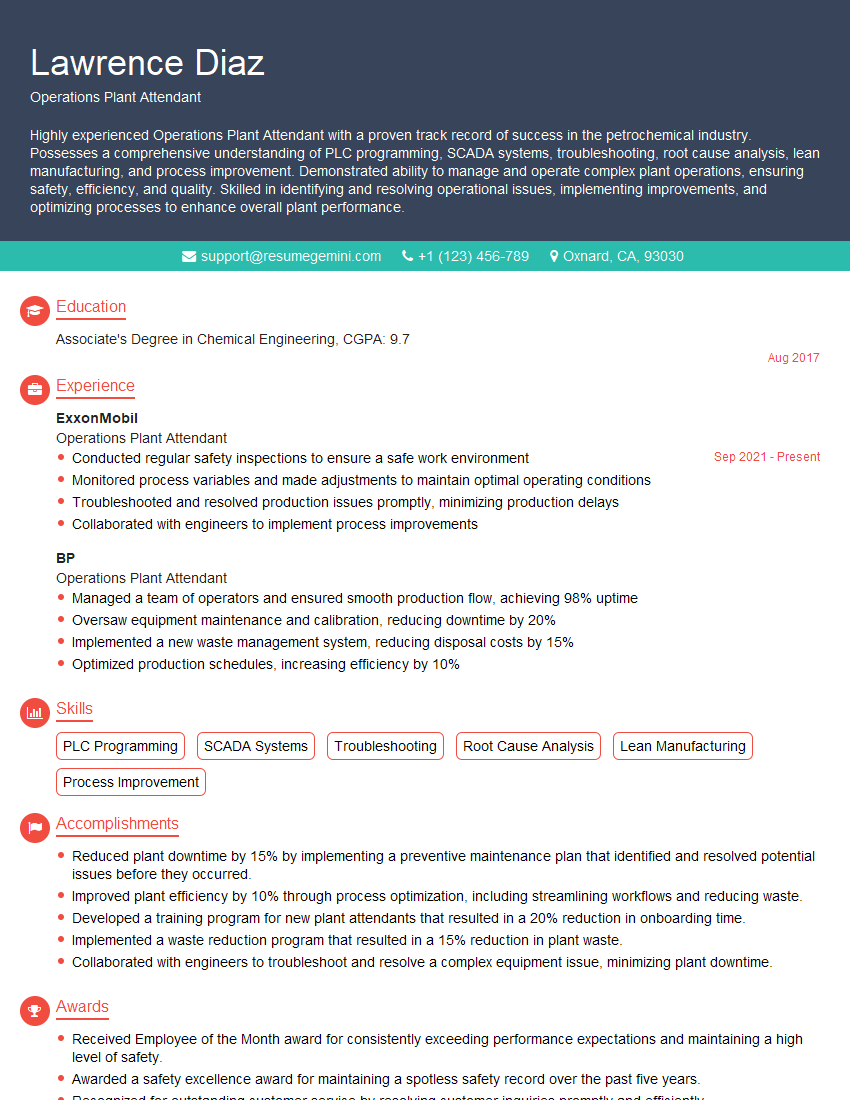

Lawrence Diaz

Operations Plant Attendant

Summary

Highly experienced Operations Plant Attendant with a proven track record of success in the petrochemical industry. Possesses a comprehensive understanding of PLC programming, SCADA systems, troubleshooting, root cause analysis, lean manufacturing, and process improvement. Demonstrated ability to manage and operate complex plant operations, ensuring safety, efficiency, and quality. Skilled in identifying and resolving operational issues, implementing improvements, and optimizing processes to enhance overall plant performance.

Education

Associate’s Degree in Chemical Engineering

August 2017

Skills

- PLC Programming

- SCADA Systems

- Troubleshooting

- Root Cause Analysis

- Lean Manufacturing

- Process Improvement

Work Experience

Operations Plant Attendant

- Conducted regular safety inspections to ensure a safe work environment

- Monitored process variables and made adjustments to maintain optimal operating conditions

- Troubleshooted and resolved production issues promptly, minimizing production delays

- Collaborated with engineers to implement process improvements

Operations Plant Attendant

- Managed a team of operators and ensured smooth production flow, achieving 98% uptime

- Oversaw equipment maintenance and calibration, reducing downtime by 20%

- Implemented a new waste management system, reducing disposal costs by 15%

- Optimized production schedules, increasing efficiency by 10%

Accomplishments

- Reduced plant downtime by 15% by implementing a preventive maintenance plan that identified and resolved potential issues before they occurred.

- Improved plant efficiency by 10% through process optimization, including streamlining workflows and reducing waste.

- Developed a training program for new plant attendants that resulted in a 20% reduction in onboarding time.

- Implemented a waste reduction program that resulted in a 15% reduction in plant waste.

- Collaborated with engineers to troubleshoot and resolve a complex equipment issue, minimizing plant downtime.

Awards

- Received Employee of the Month award for consistently exceeding performance expectations and maintaining a high level of safety.

- Awarded a safety excellence award for maintaining a spotless safety record over the past five years.

- Recognized for outstanding customer service by resolving customer inquiries promptly and efficiently.

- Awarded the Plant Managers Award for Innovation for developing a new method to improve product quality.

Certificates

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Production Technician (CPT)

- OSHA 10Hour General Industry Safety

- Lockout/Tagout (LOTO)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Operations Plant Attendant

- Highlight your technical skills in PLC programming, SCADA systems, and troubleshooting.

- Emphasize your experience in root cause analysis and process improvement.

- Quantify your accomplishments with specific metrics to demonstrate your impact on plant operations.

- Tailor your resume to the specific requirements of each job you apply for.

Essential Experience Highlights for a Strong Operations Plant Attendant Resume

- Monitored and controlled plant operations to ensure adherence to safety protocols, quality standards, and production targets.

- Utilized PLC programming and SCADA systems to optimize production processes, reduce downtime, and improve efficiency.

- Performed regular inspections, maintenance, and troubleshooting to identify and resolve operational issues.

- Conducted root cause analysis to determine the underlying causes of operational problems and implemented corrective actions.

- Applied lean manufacturing principles and process improvement techniques to streamline operations, eliminate waste, and maximize productivity.

- Collaborated with cross-functional teams to identify opportunities for improvement and implement solutions to enhance plant performance.

Frequently Asked Questions (FAQ’s) For Operations Plant Attendant

What is the role of an Operations Plant Attendant?

An Operations Plant Attendant is responsible for the safe and efficient operation of a plant or facility. They monitor and control plant operations, perform inspections and maintenance, troubleshoot and resolve operational issues, implement process improvements, and ensure adherence to safety and quality standards.

What skills are required to be an Operations Plant Attendant?

Essential skills for an Operations Plant Attendant include PLC programming, SCADA systems, troubleshooting, root cause analysis, lean manufacturing, process improvement, and a strong understanding of plant operations.

What is the career path for an Operations Plant Attendant?

With experience and additional training, Operations Plant Attendants can advance to roles such as Production Supervisor, Plant Manager, or Process Engineer.

What is the salary range for an Operations Plant Attendant?

The salary range for an Operations Plant Attendant can vary depending on experience, location, and industry. According to Indeed, the average salary for an Operations Plant Attendant in the United States is around $65,000 per year.

What are the job opportunities for Operations Plant Attendants?

Operations Plant Attendants are employed in various industries, including petrochemicals, manufacturing, pharmaceuticals, food processing, and utilities. They work in plants and facilities that produce a wide range of products, from chemicals and plastics to food and beverages.