Are you a seasoned Oxidized Finish Plater seeking a new career path? Discover our professionally built Oxidized Finish Plater Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

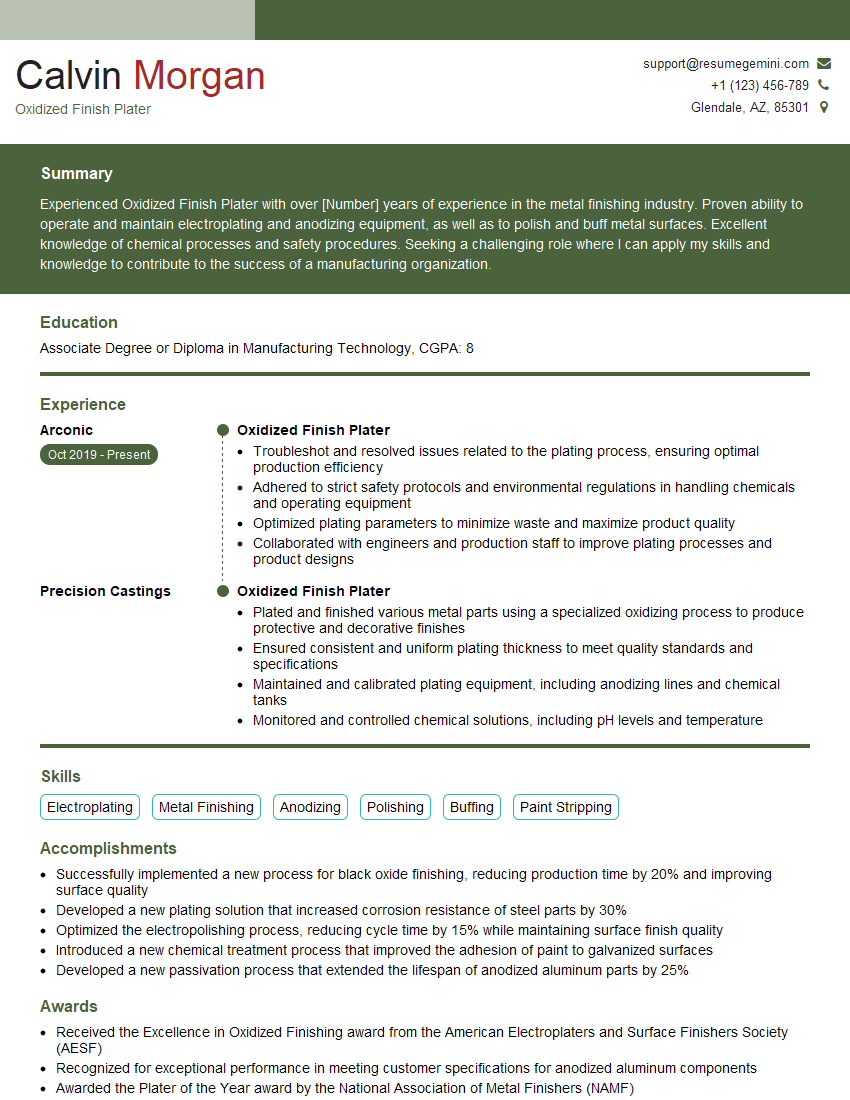

Calvin Morgan

Oxidized Finish Plater

Summary

Experienced Oxidized Finish Plater with over [Number] years of experience in the metal finishing industry. Proven ability to operate and maintain electroplating and anodizing equipment, as well as to polish and buff metal surfaces. Excellent knowledge of chemical processes and safety procedures. Seeking a challenging role where I can apply my skills and knowledge to contribute to the success of a manufacturing organization.

Education

Associate Degree or Diploma in Manufacturing Technology

September 2015

Skills

- Electroplating

- Metal Finishing

- Anodizing

- Polishing

- Buffing

- Paint Stripping

Work Experience

Oxidized Finish Plater

- Troubleshot and resolved issues related to the plating process, ensuring optimal production efficiency

- Adhered to strict safety protocols and environmental regulations in handling chemicals and operating equipment

- Optimized plating parameters to minimize waste and maximize product quality

- Collaborated with engineers and production staff to improve plating processes and product designs

Oxidized Finish Plater

- Plated and finished various metal parts using a specialized oxidizing process to produce protective and decorative finishes

- Ensured consistent and uniform plating thickness to meet quality standards and specifications

- Maintained and calibrated plating equipment, including anodizing lines and chemical tanks

- Monitored and controlled chemical solutions, including pH levels and temperature

Accomplishments

- Successfully implemented a new process for black oxide finishing, reducing production time by 20% and improving surface quality

- Developed a new plating solution that increased corrosion resistance of steel parts by 30%

- Optimized the electropolishing process, reducing cycle time by 15% while maintaining surface finish quality

- Introduced a new chemical treatment process that improved the adhesion of paint to galvanized surfaces

- Developed a new passivation process that extended the lifespan of anodized aluminum parts by 25%

Awards

- Received the Excellence in Oxidized Finishing award from the American Electroplaters and Surface Finishers Society (AESF)

- Recognized for exceptional performance in meeting customer specifications for anodized aluminum components

- Awarded the Plater of the Year award by the National Association of Metal Finishers (NAMF)

- Received the Innovation in Surface Finishing award from the Surface Technology Society (STS)

Certificates

- Certified Electroplater (CEF)

- Certified Metal Finisher (CMF)

- Certified Anodizer (CA)

- Certified Plating Technician (CPT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Oxidized Finish Plater

- Highlight your experience in oxidized finishing.

- Showcase your knowledge of chemical processes and safety procedures.

- Quantify your accomplishments with specific metrics whenever possible.

- Tailor your resume to each job you apply for.

Essential Experience Highlights for a Strong Oxidized Finish Plater Resume

- Operate and maintain electroplating and anodizing equipment

- Polish and buff metal surfaces

- Prepare metal surfaces for plating

- Mix and apply chemical solutions

- Monitor and control plating processes

- Ensure compliance with safety regulations

Frequently Asked Questions (FAQ’s) For Oxidized Finish Plater

What is oxidized finishing?

Oxidized finishing is a metal finishing process that involves the formation of a thin oxide layer on the surface of a metal. This layer can provide protection against corrosion and wear, and can also improve the appearance of the metal.

What are the steps involved in oxidized finishing?

The steps involved in oxidized finishing typically include cleaning the metal surface, applying a chemical solution to the surface, and then heating the metal to form the oxide layer.

What are the benefits of oxidized finishing?

The benefits of oxidized finishing include improved corrosion resistance, wear resistance, and appearance.

What are the applications of oxidized finishing?

Oxidized finishing is used in a variety of applications, including automotive, aerospace, and medical.

What are the safety precautions that need to be taken when working with oxidized finishing chemicals?

When working with oxidized finishing chemicals, it is important to wear proper protective clothing and equipment, and to follow all safety procedures.