Are you a seasoned Oxyacetylene Torch Operator seeking a new career path? Discover our professionally built Oxyacetylene Torch Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

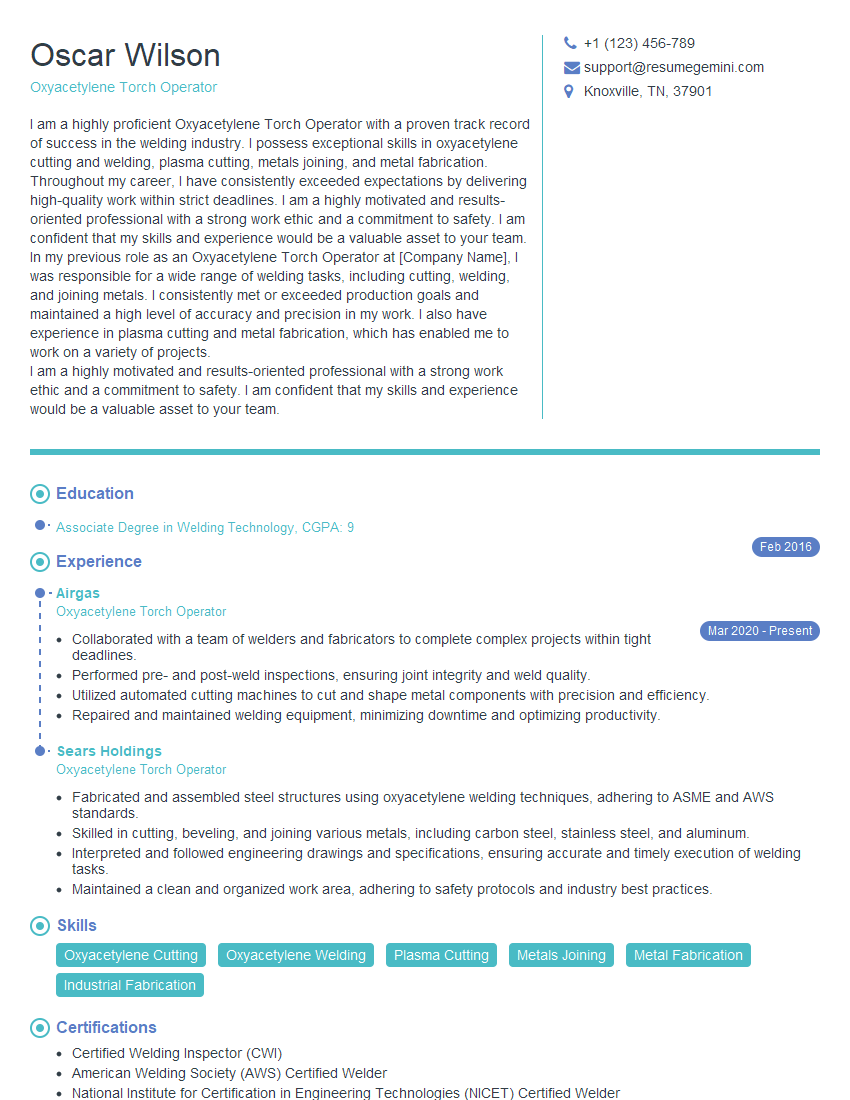

Oscar Wilson

Oxyacetylene Torch Operator

Summary

I am a highly proficient Oxyacetylene Torch Operator with a proven track record of success in the welding industry. I possess exceptional skills in oxyacetylene cutting and welding, plasma cutting, metals joining, and metal fabrication. Throughout my career, I have consistently exceeded expectations by delivering high-quality work within strict deadlines. I am a highly motivated and results-oriented professional with a strong work ethic and a commitment to safety. I am confident that my skills and experience would be a valuable asset to your team.

In my previous role as an Oxyacetylene Torch Operator at [Company Name], I was responsible for a wide range of welding tasks, including cutting, welding, and joining metals. I consistently met or exceeded production goals and maintained a high level of accuracy and precision in my work. I also have experience in plasma cutting and metal fabrication, which has enabled me to work on a variety of projects.

I am a highly motivated and results-oriented professional with a strong work ethic and a commitment to safety. I am confident that my skills and experience would be a valuable asset to your team.

Education

Associate Degree in Welding Technology

February 2016

Skills

- Oxyacetylene Cutting

- Oxyacetylene Welding

- Plasma Cutting

- Metals Joining

- Metal Fabrication

- Industrial Fabrication

Work Experience

Oxyacetylene Torch Operator

- Collaborated with a team of welders and fabricators to complete complex projects within tight deadlines.

- Performed pre- and post-weld inspections, ensuring joint integrity and weld quality.

- Utilized automated cutting machines to cut and shape metal components with precision and efficiency.

- Repaired and maintained welding equipment, minimizing downtime and optimizing productivity.

Oxyacetylene Torch Operator

- Fabricated and assembled steel structures using oxyacetylene welding techniques, adhering to ASME and AWS standards.

- Skilled in cutting, beveling, and joining various metals, including carbon steel, stainless steel, and aluminum.

- Interpreted and followed engineering drawings and specifications, ensuring accurate and timely execution of welding tasks.

- Maintained a clean and organized work area, adhering to safety protocols and industry best practices.

Certificates

- Certified Welding Inspector (CWI)

- American Welding Society (AWS) Certified Welder

- National Institute for Certification in Engineering Technologies (NICET) Certified Welder

- International Association of Certified Welders (IACW) Certified Welder

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Oxyacetylene Torch Operator

- Tailor your resume to the specific job you are applying for.

- Highlight your skills and experience in oxyacetylene cutting and welding.

- Include examples of your work and accomplishments.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Oxyacetylene Torch Operator Resume

- Operate oxyacetylene torches to cut, weld, and join metals

- Set up and adjust oxyacetylene torches to achieve desired results

- Inspect and maintain oxyacetylene torches and equipment

- Follow safety regulations and procedures

- Work independently and as part of a team

- Read and interpret blueprints and drawings

Frequently Asked Questions (FAQ’s) For Oxyacetylene Torch Operator

What is an Oxyacetylene Torch Operator?

An Oxyacetylene Torch Operator uses oxyacetylene torches to cut, weld, and join metals. They set up and adjust oxyacetylene torches to achieve desired results, inspect and maintain oxyacetylene torches and equipment, and follow safety regulations and procedures. Oxyacetylene Torch Operators may work independently or as part of a team, and they must be able to read and interpret blueprints and drawings.

What are the skills and experience required to be an Oxyacetylene Torch Operator?

Oxyacetylene Torch Operators need to have skills in oxyacetylene cutting and welding, plasma cutting, metals joining, and metal fabrication. They also need to be able to set up and adjust oxyacetylene torches, inspect and maintain oxyacetylene torches and equipment, and follow safety regulations and procedures. Oxyacetylene Torch Operators typically have a high school diploma or equivalent, and some may have an associate degree in welding technology.

What is the work environment of an Oxyacetylene Torch Operator?

Oxyacetylene Torch Operators typically work in industrial settings, such as factories, workshops, and construction sites. They may work indoors or outdoors, and they may be exposed to hazardous fumes and gases. Oxyacetylene Torch Operators must wear protective clothing and equipment, such as gloves, goggles, and respirators, to protect themselves from injury.

What is the salary of an Oxyacetylene Torch Operator?

The salary of an Oxyacetylene Torch Operator can vary depending on their experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for welders, cutters, solderers, and brazers was $45,760 in May 2021.

What is the job outlook for Oxyacetylene Torch Operators?

The job outlook for Oxyacetylene Torch Operators is expected to be good over the next few years. The demand for welders, cutters, solderers, and brazers is expected to grow as the construction industry recovers from the COVID-19 pandemic. Oxyacetylene Torch Operators with experience in plasma cutting and metal fabrication will be in high demand.

What are the benefits of being an Oxyacetylene Torch Operator?

There are many benefits to being an Oxyacetylene Torch Operator, including:

- Good pay: Oxyacetylene Torch Operators can earn a good salary, especially those with experience in plasma cutting and metal fabrication.

- Job security: The job outlook for Oxyacetylene Torch Operators is expected to be good over the next few years.

- Opportunities for advancement: Oxyacetylene Torch Operators can advance to positions such as welding supervisor or welding engineer.

- Satisfaction: Oxyacetylene Torch Operators can take pride in their work, knowing that they are helping to build and repair important structures.

What are the challenges of being an Oxyacetylene Torch Operator?

There are some challenges to being an Oxyacetylene Torch Operator, including:

- Hazardous work environment: Oxyacetylene Torch Operators may be exposed to hazardous fumes and gases, and they must wear protective clothing and equipment to protect themselves from injury.

- Physical demands: Oxyacetylene Torch Operators may have to work in awkward positions or lift heavy objects.

- Repetitive work: Oxyacetylene Torch Operators may have to perform the same tasks over and over again.

- Stress: Oxyacetylene Torch Operators may be under pressure to meet deadlines or to produce high-quality work.