Are you a seasoned Pantograph Machine Operator seeking a new career path? Discover our professionally built Pantograph Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

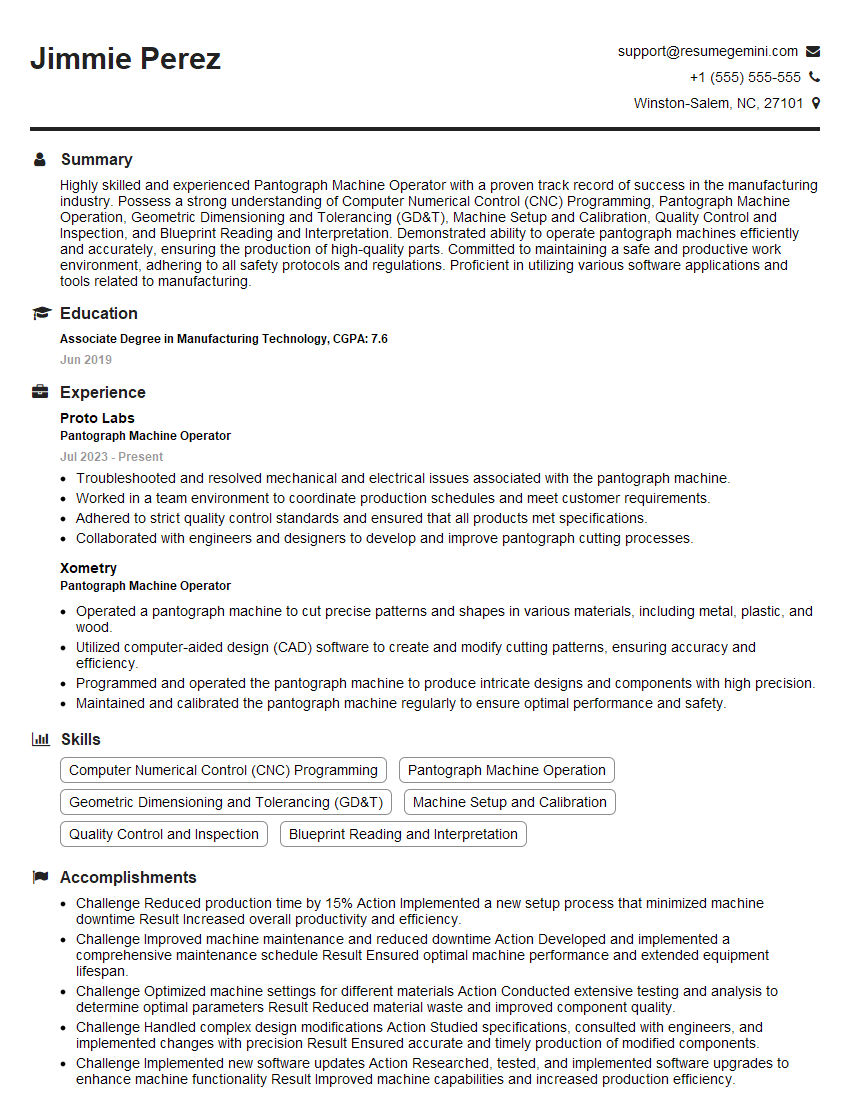

Jimmie Perez

Pantograph Machine Operator

Summary

Highly skilled and experienced Pantograph Machine Operator with a proven track record of success in the manufacturing industry. Possess a strong understanding of Computer Numerical Control (CNC) Programming, Pantograph Machine Operation, Geometric Dimensioning and Tolerancing (GD&T), Machine Setup and Calibration, Quality Control and Inspection, and Blueprint Reading and Interpretation. Demonstrated ability to operate pantograph machines efficiently and accurately, ensuring the production of high-quality parts. Committed to maintaining a safe and productive work environment, adhering to all safety protocols and regulations. Proficient in utilizing various software applications and tools related to manufacturing.

Education

Associate Degree in Manufacturing Technology

June 2019

Skills

- Computer Numerical Control (CNC) Programming

- Pantograph Machine Operation

- Geometric Dimensioning and Tolerancing (GD&T)

- Machine Setup and Calibration

- Quality Control and Inspection

- Blueprint Reading and Interpretation

Work Experience

Pantograph Machine Operator

- Troubleshooted and resolved mechanical and electrical issues associated with the pantograph machine.

- Worked in a team environment to coordinate production schedules and meet customer requirements.

- Adhered to strict quality control standards and ensured that all products met specifications.

- Collaborated with engineers and designers to develop and improve pantograph cutting processes.

Pantograph Machine Operator

- Operated a pantograph machine to cut precise patterns and shapes in various materials, including metal, plastic, and wood.

- Utilized computer-aided design (CAD) software to create and modify cutting patterns, ensuring accuracy and efficiency.

- Programmed and operated the pantograph machine to produce intricate designs and components with high precision.

- Maintained and calibrated the pantograph machine regularly to ensure optimal performance and safety.

Accomplishments

- Challenge Reduced production time by 15% Action Implemented a new setup process that minimized machine downtime Result Increased overall productivity and efficiency.

- Challenge Improved machine maintenance and reduced downtime Action Developed and implemented a comprehensive maintenance schedule Result Ensured optimal machine performance and extended equipment lifespan.

- Challenge Optimized machine settings for different materials Action Conducted extensive testing and analysis to determine optimal parameters Result Reduced material waste and improved component quality.

- Challenge Handled complex design modifications Action Studied specifications, consulted with engineers, and implemented changes with precision Result Ensured accurate and timely production of modified components.

- Challenge Implemented new software updates Action Researched, tested, and implemented software upgrades to enhance machine functionality Result Improved machine capabilities and increased production efficiency.

Awards

- Received the Operator of the Quarter award for consistently exceeding production targets and maintaining highquality standards.

- Recognized for exceptional attention to detail and accuracy, consistently producing defectfree components.

- Awarded for outstanding safety performance, maintaining a spotless safety record and adhering to all safety protocols.

- Recognized for exemplary teamwork and collaboration, consistently exceeding expectations in a team environment.

Certificates

- Pantograph Machine Operator Certification

- ISO 9001:2015 Quality Management System

- OSHA Safety Certification

- Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pantograph Machine Operator

- Highlight your experience in operating pantograph machines and your understanding of CNC Programming and GD&T.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your knowledge of quality control and inspection procedures, and your commitment to producing high-quality parts.

- Emphasize your ability to work independently and as part of a team, and your attention to detail and accuracy.

Essential Experience Highlights for a Strong Pantograph Machine Operator Resume

- Operate pantograph machines to cut, shape, and engrave materials according to specifications.

- Interpret blueprints and drawings, and determine the appropriate cutting parameters.

- Set up and calibrate machines, ensuring accuracy and precision.

- Conduct quality control inspections to ensure parts meet specifications.

- Maintain a clean and organized work area, and adhere to all safety protocols.

- Troubleshoot and resolve machine malfunctions, ensuring minimal downtime.

- Collaborate with engineers and other team members to optimize production processes.

Frequently Asked Questions (FAQ’s) For Pantograph Machine Operator

What is a Pantograph Machine Operator?

A Pantograph Machine Operator is responsible for operating pantograph machines to cut, shape, and engrave materials according to specifications. They interpret blueprints and drawings, set up and calibrate machines, conduct quality control inspections, and troubleshoot machine malfunctions.

What skills are required to be a successful Pantograph Machine Operator?

Successful Pantograph Machine Operators typically have a strong understanding of Computer Numerical Control (CNC) Programming, Pantograph Machine Operation, Geometric Dimensioning and Tolerancing (GD&T), Machine Setup and Calibration, Quality Control and Inspection, and Blueprint Reading and Interpretation.

What is the work environment like for a Pantograph Machine Operator?

Pantograph Machine Operators typically work in manufacturing environments, operating machines in a production setting. They may work independently or as part of a team, and must be able to work in a fast-paced environment.

What is the career outlook for Pantograph Machine Operators?

The career outlook for Pantograph Machine Operators is expected to be good, with a projected 7% growth in employment from 2020 to 2030.

What is the average salary for a Pantograph Machine Operator?

The average salary for a Pantograph Machine Operator in the United States is around $20 per hour.

What are the benefits of working as a Pantograph Machine Operator?

Benefits of working as a Pantograph Machine Operator include job security, opportunities for advancement, and a competitive salary.

What are some tips for writing a standout Pantograph Machine Operator resume?

Tips for writing a standout Pantograph Machine Operator resume include highlighting your experience in operating pantograph machines and your understanding of CNC Programming and GD&T, quantifying your accomplishments whenever possible, showcasing your knowledge of quality control and inspection procedures, and emphasizing your ability to work independently and as part of a team.