Are you a seasoned Pattern Molder seeking a new career path? Discover our professionally built Pattern Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

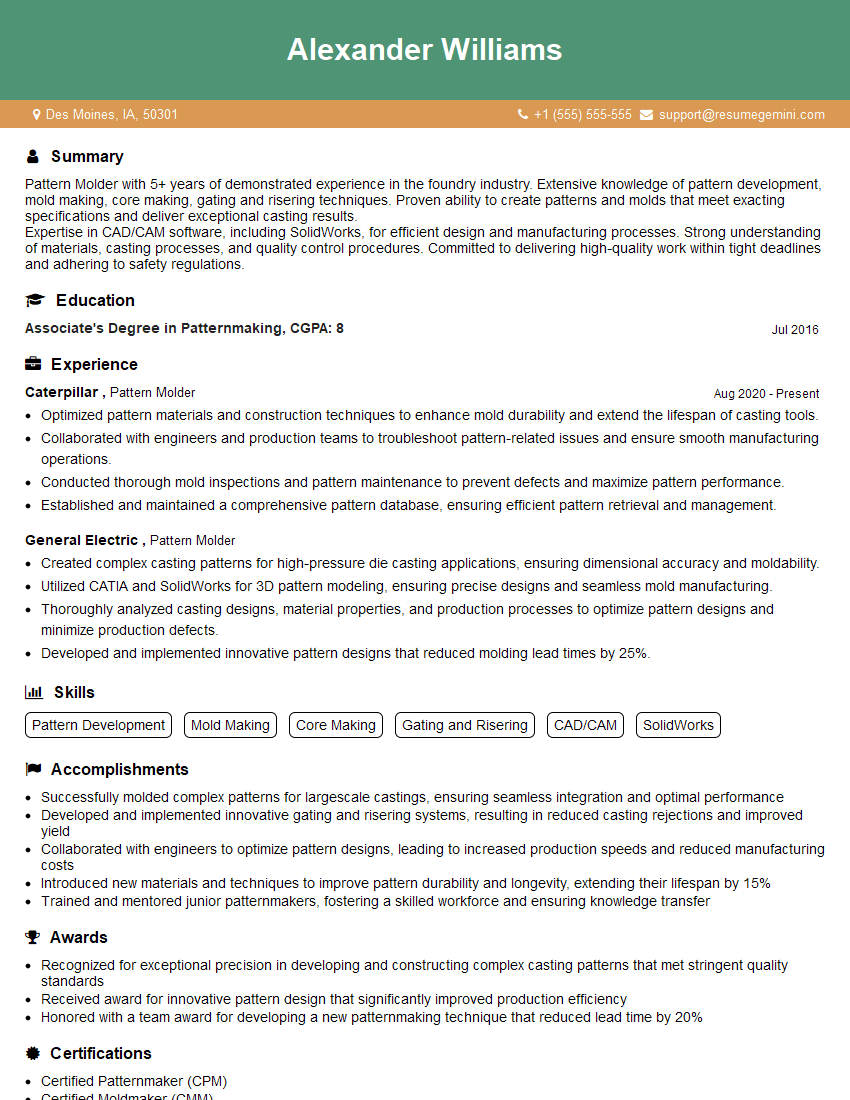

Alexander Williams

Pattern Molder

Summary

Pattern Molder with 5+ years of demonstrated experience in the foundry industry. Extensive knowledge of pattern development, mold making, core making, gating and risering techniques. Proven ability to create patterns and molds that meet exacting specifications and deliver exceptional casting results.

Expertise in CAD/CAM software, including SolidWorks, for efficient design and manufacturing processes. Strong understanding of materials, casting processes, and quality control procedures. Committed to delivering high-quality work within tight deadlines and adhering to safety regulations.

Education

Associate’s Degree in Patternmaking

July 2016

Skills

- Pattern Development

- Mold Making

- Core Making

- Gating and Risering

- CAD/CAM

- SolidWorks

Work Experience

Pattern Molder

- Optimized pattern materials and construction techniques to enhance mold durability and extend the lifespan of casting tools.

- Collaborated with engineers and production teams to troubleshoot pattern-related issues and ensure smooth manufacturing operations.

- Conducted thorough mold inspections and pattern maintenance to prevent defects and maximize pattern performance.

- Established and maintained a comprehensive pattern database, ensuring efficient pattern retrieval and management.

Pattern Molder

- Created complex casting patterns for high-pressure die casting applications, ensuring dimensional accuracy and moldability.

- Utilized CATIA and SolidWorks for 3D pattern modeling, ensuring precise designs and seamless mold manufacturing.

- Thoroughly analyzed casting designs, material properties, and production processes to optimize pattern designs and minimize production defects.

- Developed and implemented innovative pattern designs that reduced molding lead times by 25%.

Accomplishments

- Successfully molded complex patterns for largescale castings, ensuring seamless integration and optimal performance

- Developed and implemented innovative gating and risering systems, resulting in reduced casting rejections and improved yield

- Collaborated with engineers to optimize pattern designs, leading to increased production speeds and reduced manufacturing costs

- Introduced new materials and techniques to improve pattern durability and longevity, extending their lifespan by 15%

- Trained and mentored junior patternmakers, fostering a skilled workforce and ensuring knowledge transfer

Awards

- Recognized for exceptional precision in developing and constructing complex casting patterns that met stringent quality standards

- Received award for innovative pattern design that significantly improved production efficiency

- Honored with a team award for developing a new patternmaking technique that reduced lead time by 20%

Certificates

- Certified Patternmaker (CPM)

- Certified Moldmaker (CMM)

- ASME B46.1-2019 Foundry Dimensional Gages and Gaging Practices

- Certified SolidWorks Associate (CSWA)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pattern Molder

- Quantify your accomplishments with specific metrics to demonstrate your impact.

- Highlight your experience with specific casting processes, such as investment casting or sand casting.

- Showcase your proficiency in CAD/CAM software, providing examples of your work.

- Emphasize your understanding of quality control procedures and your commitment to delivering high-quality results.

Essential Experience Highlights for a Strong Pattern Molder Resume

- Design and develop patterns and molds for castings using CAD/CAM software, ensuring accuracy and precision.

- Analyze casting drawings and determine appropriate pattern and mold configurations to meet production requirements.

- Fabricate patterns and molds using a variety of materials, including wood, metal, and composites.

- Inspect patterns and molds to ensure they meet specifications and industry standards.

- Assist with casting operations, including setup, pouring, and mold removal.

- Troubleshoot and resolve issues related to pattern and mold design, fabrication, and casting processes.

- Maintain a clean and organized work area, adhering to safety protocols and industry best practices.

Frequently Asked Questions (FAQ’s) For Pattern Molder

What are the primary responsibilities of a Pattern Molder?

Pattern Molders are responsible for designing and developing patterns and molds for castings, ensuring accuracy and precision. They analyze casting drawings, fabricate patterns and molds, and inspect them to ensure they meet specifications. They also assist with casting operations and troubleshoot issues related to the pattern and mold design, fabrication, and casting processes.

What skills are required to become a successful Pattern Molder?

Pattern Molders typically need an associate’s degree in patternmaking or a related field. They should have strong knowledge of pattern development, mold making, core making, gating, and risering techniques. Proficiency in CAD/CAM software, such as SolidWorks, is also essential. Additionally, Pattern Molders should have a good understanding of materials, casting processes, and quality control procedures.

What are the career prospects for Pattern Molders?

Pattern Molders can advance their careers by specializing in a particular area of patternmaking, such as investment casting or sand casting. They can also move into management roles, such as Pattern Shop Supervisor or Foundry Manager. With experience and additional training, Pattern Molders can also become Casting Engineers or Quality Control Inspectors.

What is the average salary for a Pattern Molder?

According to the U.S. Bureau of Labor Statistics, the median annual salary for Pattern Molders was $49,970 in May 2021. The lowest 10 percent earned less than $36,340, and the highest 10 percent earned more than $79,380.

What are the typical working conditions for a Pattern Molder?

Pattern Molders typically work in foundries or pattern shops. They may be exposed to noise, dust, and fumes. They may also need to lift heavy objects and work in awkward positions.

What are the educational requirements for a Pattern Molder?

Most Pattern Molders have an associate’s degree in patternmaking or a related field. Some employers may also require Pattern Molders to have a high school diploma or GED.

What are the certification requirements for a Pattern Molder?

There are no specific certification requirements for Pattern Molders. However, some employers may prefer to hire Pattern Molders who have completed a certified apprenticeship program.

What are the job outlook prospects for Pattern Molders?

The job outlook for Pattern Molders is expected to be good over the next few years. The demand for Pattern Molders is expected to increase as the manufacturing industry continues to grow.