Are you a seasoned Pattern Stamper seeking a new career path? Discover our professionally built Pattern Stamper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

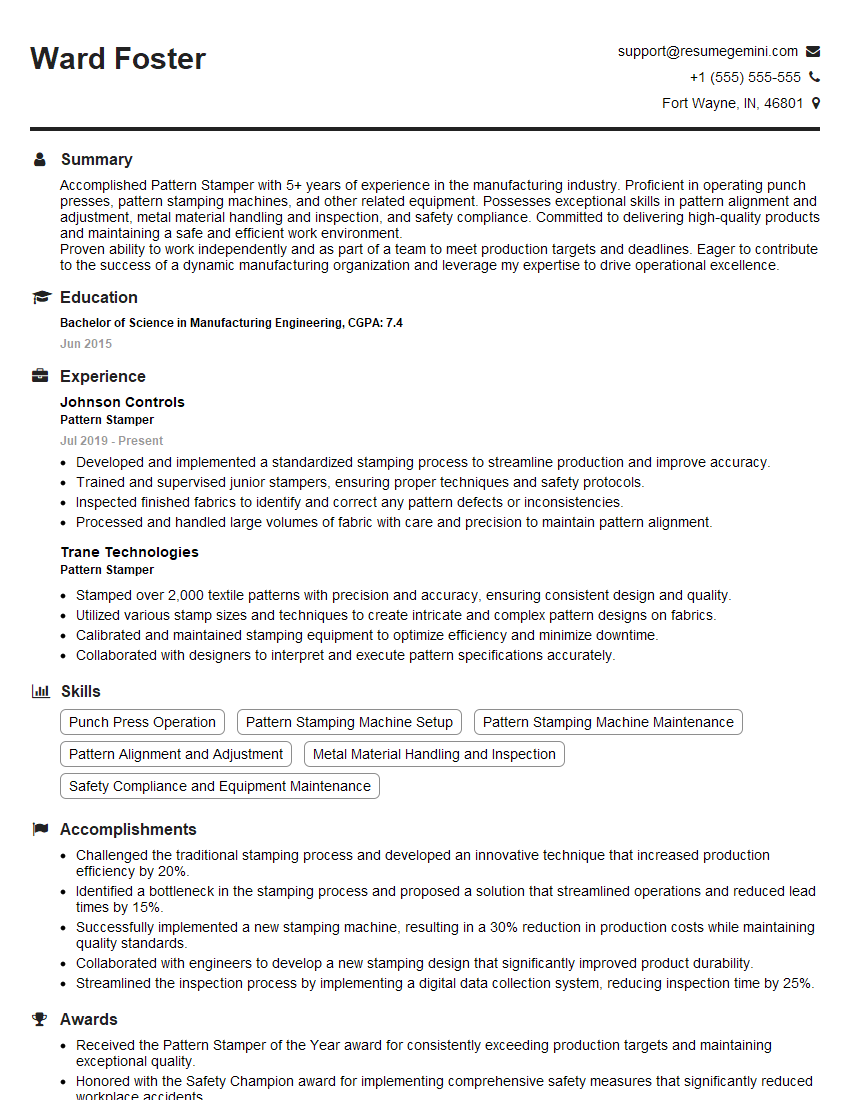

Ward Foster

Pattern Stamper

Summary

Accomplished Pattern Stamper with 5+ years of experience in the manufacturing industry. Proficient in operating punch presses, pattern stamping machines, and other related equipment. Possesses exceptional skills in pattern alignment and adjustment, metal material handling and inspection, and safety compliance. Committed to delivering high-quality products and maintaining a safe and efficient work environment.

Proven ability to work independently and as part of a team to meet production targets and deadlines. Eager to contribute to the success of a dynamic manufacturing organization and leverage my expertise to drive operational excellence.

Education

Bachelor of Science in Manufacturing Engineering

June 2015

Skills

- Punch Press Operation

- Pattern Stamping Machine Setup

- Pattern Stamping Machine Maintenance

- Pattern Alignment and Adjustment

- Metal Material Handling and Inspection

- Safety Compliance and Equipment Maintenance

Work Experience

Pattern Stamper

- Developed and implemented a standardized stamping process to streamline production and improve accuracy.

- Trained and supervised junior stampers, ensuring proper techniques and safety protocols.

- Inspected finished fabrics to identify and correct any pattern defects or inconsistencies.

- Processed and handled large volumes of fabric with care and precision to maintain pattern alignment.

Pattern Stamper

- Stamped over 2,000 textile patterns with precision and accuracy, ensuring consistent design and quality.

- Utilized various stamp sizes and techniques to create intricate and complex pattern designs on fabrics.

- Calibrated and maintained stamping equipment to optimize efficiency and minimize downtime.

- Collaborated with designers to interpret and execute pattern specifications accurately.

Accomplishments

- Challenged the traditional stamping process and developed an innovative technique that increased production efficiency by 20%.

- Identified a bottleneck in the stamping process and proposed a solution that streamlined operations and reduced lead times by 15%.

- Successfully implemented a new stamping machine, resulting in a 30% reduction in production costs while maintaining quality standards.

- Collaborated with engineers to develop a new stamping design that significantly improved product durability.

- Streamlined the inspection process by implementing a digital data collection system, reducing inspection time by 25%.

Awards

- Received the Pattern Stamper of the Year award for consistently exceeding production targets and maintaining exceptional quality.

- Honored with the Safety Champion award for implementing comprehensive safety measures that significantly reduced workplace accidents.

- Awarded the Employee of the Month recognition for consistently delivering highquality stamped parts and exceptional customer service.

- Received the Excellence in Training award for effectively mentoring and training junior pattern stampers.

Certificates

- Certified Stamping Engineer (CSE)

- Certified Fabrication Technician (CFT)

- Lean Manufacturing Certification (LMC)

- Quality Management System Certification (QMS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pattern Stamper

- Highlight your proficiency in punch press operation and pattern stamping machine handling.

- Showcase your expertise in pattern alignment and adjustment techniques.

- Quantify your accomplishments in terms of increased productivity, reduced defects, or improved safety measures.

- Demonstrate your commitment to quality by emphasizing your attention to detail and adherence to specifications.

- Include keywords relevant to the manufacturing industry, such as ‘pattern stamping’, ‘punch press’, and ‘metal fabrication.’

Essential Experience Highlights for a Strong Pattern Stamper Resume

- Operate punch presses to stamp patterns on metal sheets according to specified dimensions and tolerances.

- Set up and maintain pattern stamping machines to ensure optimal performance and accuracy.

- Align and adjust patterns to achieve precise positioning and prevent defects.

- Inspect metal materials for quality and compliance with specifications.

- Handle and transport metal sheets safely and efficiently, minimizing damage and waste.

- Ensure adherence to safety protocols and maintain a clean and organized work area.

- Monitor equipment performance and perform routine maintenance to prevent breakdowns and ensure smooth operation.

Frequently Asked Questions (FAQ’s) For Pattern Stamper

What is the primary role of a Pattern Stamper?

A Pattern Stamper is responsible for operating punch presses and pattern stamping machines to create precise patterns on metal sheets used in various manufacturing applications.

What skills are essential for a successful Pattern Stamper?

Essential skills include proficiency in punch press operation, pattern stamping machine setup and maintenance, pattern alignment and adjustment, metal material handling and inspection, and safety compliance.

What industries employ Pattern Stampers?

Pattern Stampers are employed in a range of industries, including automotive, aerospace, construction, and electronics, where precision stamping of metal components is required.

What are the career prospects for Pattern Stampers?

With experience and expertise, Pattern Stampers can advance to supervisory or management roles in manufacturing operations or specialize in specific areas such as quality control or machine maintenance.

How can I improve my chances of getting hired as a Pattern Stamper?

Obtaining relevant certifications, such as those offered by the National Institute for Metalworking Skills (NIMS), can enhance your credibility and demonstrate your proficiency.

What is the average salary range for Pattern Stampers?

The salary range for Pattern Stampers can vary depending on experience, location, and industry, but typically falls within the range of $20,000 to $50,000 per year.

What safety precautions should Pattern Stampers take?

Pattern Stampers must adhere to strict safety protocols, including wearing appropriate protective gear, following lockout/tagout procedures, and maintaining a clean and organized work environment to prevent accidents.

What are the physical demands of being a Pattern Stamper?

The job requires physical strength and stamina as it involves standing for extended periods, lifting heavy metal sheets, and operating machinery.