Are you a seasoned Photochemical Etcher seeking a new career path? Discover our professionally built Photochemical Etcher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

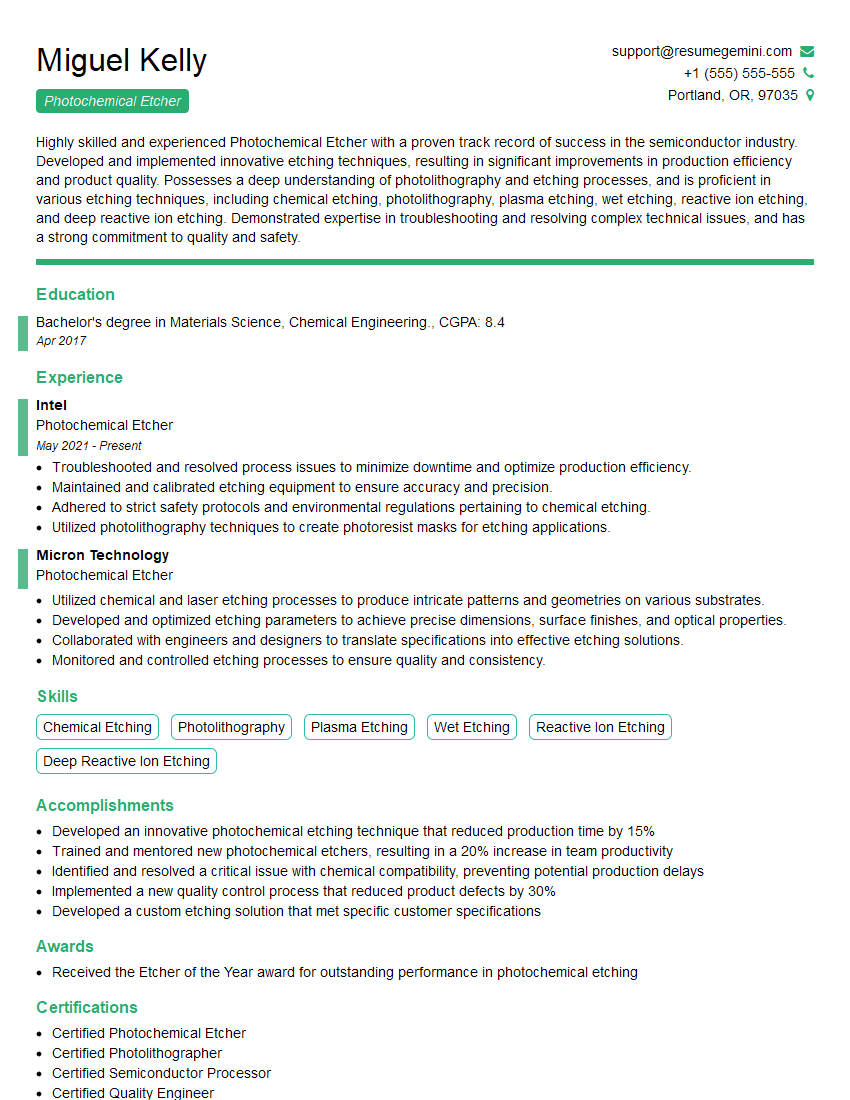

Miguel Kelly

Photochemical Etcher

Summary

Highly skilled and experienced Photochemical Etcher with a proven track record of success in the semiconductor industry. Developed and implemented innovative etching techniques, resulting in significant improvements in production efficiency and product quality. Possesses a deep understanding of photolithography and etching processes, and is proficient in various etching techniques, including chemical etching, photolithography, plasma etching, wet etching, reactive ion etching, and deep reactive ion etching. Demonstrated expertise in troubleshooting and resolving complex technical issues, and has a strong commitment to quality and safety.

Education

Bachelor’s degree in Materials Science, Chemical Engineering.

April 2017

Skills

- Chemical Etching

- Photolithography

- Plasma Etching

- Wet Etching

- Reactive Ion Etching

- Deep Reactive Ion Etching

Work Experience

Photochemical Etcher

- Troubleshooted and resolved process issues to minimize downtime and optimize production efficiency.

- Maintained and calibrated etching equipment to ensure accuracy and precision.

- Adhered to strict safety protocols and environmental regulations pertaining to chemical etching.

- Utilized photolithography techniques to create photoresist masks for etching applications.

Photochemical Etcher

- Utilized chemical and laser etching processes to produce intricate patterns and geometries on various substrates.

- Developed and optimized etching parameters to achieve precise dimensions, surface finishes, and optical properties.

- Collaborated with engineers and designers to translate specifications into effective etching solutions.

- Monitored and controlled etching processes to ensure quality and consistency.

Accomplishments

- Developed an innovative photochemical etching technique that reduced production time by 15%

- Trained and mentored new photochemical etchers, resulting in a 20% increase in team productivity

- Identified and resolved a critical issue with chemical compatibility, preventing potential production delays

- Implemented a new quality control process that reduced product defects by 30%

- Developed a custom etching solution that met specific customer specifications

Awards

- Received the Etcher of the Year award for outstanding performance in photochemical etching

Certificates

- Certified Photochemical Etcher

- Certified Photolithographer

- Certified Semiconductor Processor

- Certified Quality Engineer

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Photochemical Etcher

- Highlight your skills and experience in photolithography and etching techniques.

- Demonstrate your ability to troubleshoot and resolve complex technical issues.

- Quantify your accomplishments and provide specific examples of how you have improved efficiency or quality.

- Showcase your commitment to quality and safety.

- Tailor your resume to the specific job descriptions you are applying for.

Essential Experience Highlights for a Strong Photochemical Etcher Resume

- Develop and optimize photochemical etching processes to achieve desired product specifications.

- Operate and maintain photochemical etching equipment, including photoresist application, exposure, and development systems.

- Inspect and analyze etched products to ensure compliance with quality standards.

- Troubleshoot and resolve technical issues related to etching processes and equipment.

- Implement and maintain quality control procedures to ensure product quality and consistency.

- Collaborate with cross-functional teams to develop and implement process improvements.

- Stay abreast of the latest advancements in photochemical etching technology and techniques.

Frequently Asked Questions (FAQ’s) For Photochemical Etcher

What is photochemical etching?

Photochemical etching is a manufacturing process that uses light to create patterns on a metal surface. A photoresist is applied to the metal surface, and then a mask is used to block out the areas that are not to be etched. The metal is then exposed to light, which causes the photoresist to harden in the exposed areas. The metal is then etched in a chemical solution, which removes the metal in the areas that were not protected by the photoresist.

What are the different types of photochemical etching?

There are three main types of photochemical etching: chemical etching, plasma etching, and wet etching.

– What are the applications of photochemical etching?

Photochemical etching is used in a wide variety of applications, including the manufacture of printed circuit boards, solar cells, and medical devices.

What are the advantages of photochemical etching?

Photochemical etching offers a number of advantages over other etching methods, including high precision, low cost, and the ability to create complex patterns.

What are the disadvantages of photochemical etching?

Photochemical etching can be a slow process, and it can be difficult to control the depth of the etch.

What is the future of photochemical etching?

Photochemical etching is a mature technology, but it is still being used in new and innovative applications. As the demand for electronic devices continues to grow, photochemical etching is likely to remain an important manufacturing process.