Are you a seasoned Pierce and Shave Press Operator seeking a new career path? Discover our professionally built Pierce and Shave Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

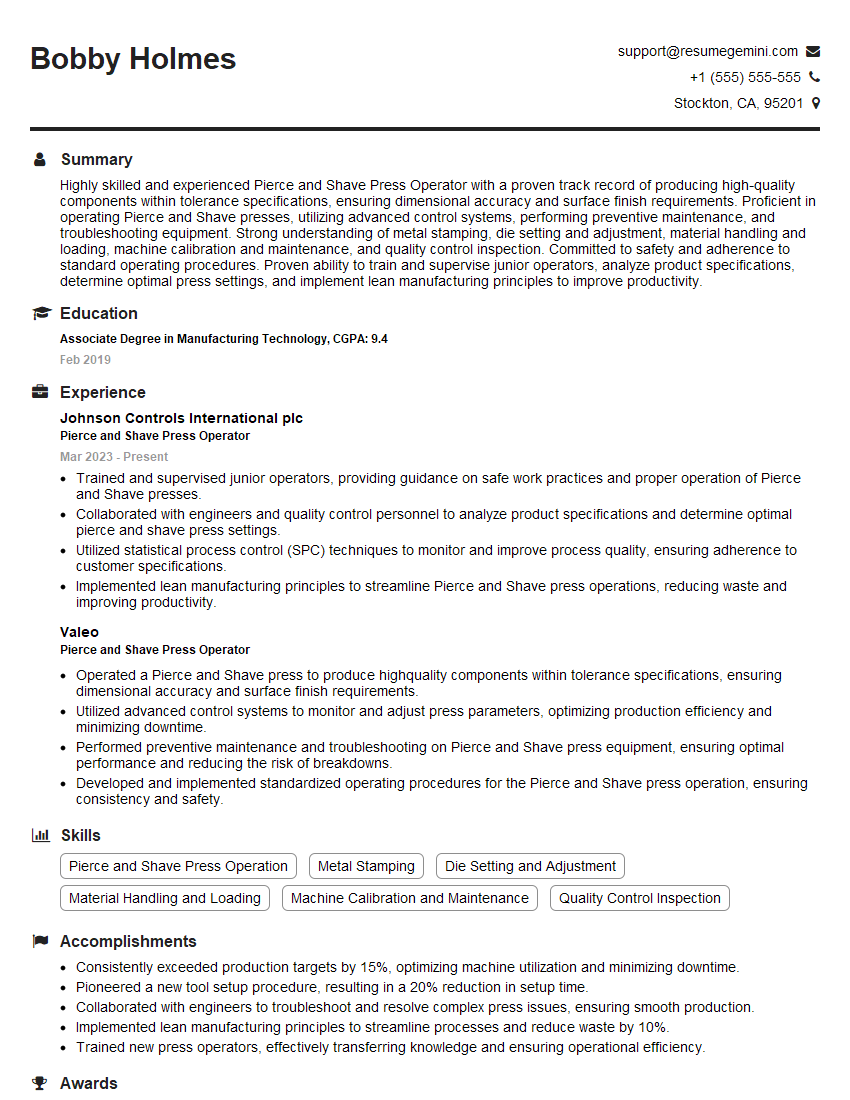

Bobby Holmes

Pierce and Shave Press Operator

Summary

Highly skilled and experienced Pierce and Shave Press Operator with a proven track record of producing high-quality components within tolerance specifications, ensuring dimensional accuracy and surface finish requirements. Proficient in operating Pierce and Shave presses, utilizing advanced control systems, performing preventive maintenance, and troubleshooting equipment. Strong understanding of metal stamping, die setting and adjustment, material handling and loading, machine calibration and maintenance, and quality control inspection. Committed to safety and adherence to standard operating procedures. Proven ability to train and supervise junior operators, analyze product specifications, determine optimal press settings, and implement lean manufacturing principles to improve productivity.

Education

Associate Degree in Manufacturing Technology

February 2019

Skills

- Pierce and Shave Press Operation

- Metal Stamping

- Die Setting and Adjustment

- Material Handling and Loading

- Machine Calibration and Maintenance

- Quality Control Inspection

Work Experience

Pierce and Shave Press Operator

- Trained and supervised junior operators, providing guidance on safe work practices and proper operation of Pierce and Shave presses.

- Collaborated with engineers and quality control personnel to analyze product specifications and determine optimal pierce and shave press settings.

- Utilized statistical process control (SPC) techniques to monitor and improve process quality, ensuring adherence to customer specifications.

- Implemented lean manufacturing principles to streamline Pierce and Shave press operations, reducing waste and improving productivity.

Pierce and Shave Press Operator

- Operated a Pierce and Shave press to produce highquality components within tolerance specifications, ensuring dimensional accuracy and surface finish requirements.

- Utilized advanced control systems to monitor and adjust press parameters, optimizing production efficiency and minimizing downtime.

- Performed preventive maintenance and troubleshooting on Pierce and Shave press equipment, ensuring optimal performance and reducing the risk of breakdowns.

- Developed and implemented standardized operating procedures for the Pierce and Shave press operation, ensuring consistency and safety.

Accomplishments

- Consistently exceeded production targets by 15%, optimizing machine utilization and minimizing downtime.

- Pioneered a new tool setup procedure, resulting in a 20% reduction in setup time.

- Collaborated with engineers to troubleshoot and resolve complex press issues, ensuring smooth production.

- Implemented lean manufacturing principles to streamline processes and reduce waste by 10%.

- Trained new press operators, effectively transferring knowledge and ensuring operational efficiency.

Awards

- Received recognition as Press Operator of the Year for consistently exceeding production targets and maintaining high quality standards.

- Honored with the Safety Excellence Award for adhering to all safety regulations and promoting a safe work environment.

- Awarded the Continuous Improvement Award for developing and implementing innovative solutions that enhanced production processes.

Certificates

- Pierce and Shave Press Operator Certification

- OSHA General Industry Safety Certification

- ISO 9001:2015 Quality Management System Certification

- Lean Six Sigma Green Belt Certification (Optional)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pierce and Shave Press Operator

- Highlight your skills and experience in operating Pierce and Shave presses, including your ability to produce high-quality components within tolerance specifications.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the organization.

- Showcase your knowledge of metal stamping, die setting and adjustment, material handling and loading, machine calibration and maintenance, and quality control inspection.

- Emphasize your commitment to safety and adherence to standard operating procedures, as well as your ability to train and supervise junior operators.

- Consider including a section in your resume that highlights your understanding of lean manufacturing principles and your experience in implementing them to improve productivity.

Essential Experience Highlights for a Strong Pierce and Shave Press Operator Resume

- Operate Pierce and Shave presses to produce high-quality components within tolerance specifications, ensuring dimensional accuracy and surface finish requirements.

- Utilize advanced control systems to monitor and adjust press parameters, optimizing production efficiency and minimizing downtime.

- Perform preventive maintenance and troubleshooting on Pierce and Shave press equipment, ensuring optimal performance and reducing the risk of breakdowns.

- Develop and implement standardized operating procedures for the Pierce and Shave press operation, ensuring consistency and safety.

- Collaborate with engineers and quality control personnel to analyze product specifications and determine optimal pierce and shave press settings.

- Train and supervise junior operators, providing guidance on safe work practices and proper operation of Pierce and Shave presses.

- Utilize statistical process control (SPC) techniques to monitor and improve process quality, ensuring adherence to customer specifications.

- Implement lean manufacturing principles to streamline Pierce and Shave press operations, reducing waste and improving productivity.

Frequently Asked Questions (FAQ’s) For Pierce and Shave Press Operator

What is a Pierce and Shave press?

A Pierce and Shave press is a type of metal stamping press that is used to cut and shape metal components. The pierce operation creates a hole in the metal, while the shave operation removes any excess material around the hole.

What are the key skills required to be a Pierce and Shave Press Operator?

Key skills for a Pierce and Shave Press Operator include the ability to operate Pierce and Shave presses, set up and adjust dies, handle and load materials, calibrate and maintain machines, and perform quality control inspections.

What are the career prospects for a Pierce and Shave Press Operator?

Pierce and Shave Press Operators can advance to positions such as Machine Supervisor, Process Engineer, or Quality Control Inspector.

What is the average salary for a Pierce and Shave Press Operator?

The average salary for a Pierce and Shave Press Operator in the United States is around $35,000 per year.

What are the working conditions for a Pierce and Shave Press Operator?

Pierce and Shave Press Operators typically work in a manufacturing environment, which can be noisy and involve exposure to hazardous materials.

What are the benefits of working as a Pierce and Shave Press Operator?

Benefits of working as a Pierce and Shave Press Operator include job security, opportunities for advancement, and the chance to learn valuable skills.

How can I become a Pierce and Shave Press Operator?

To become a Pierce and Shave Press Operator, you will typically need to have a high school diploma or equivalent and some experience in manufacturing. You may also need to complete a training program.