Are you a seasoned Pig Furnace Operator seeking a new career path? Discover our professionally built Pig Furnace Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

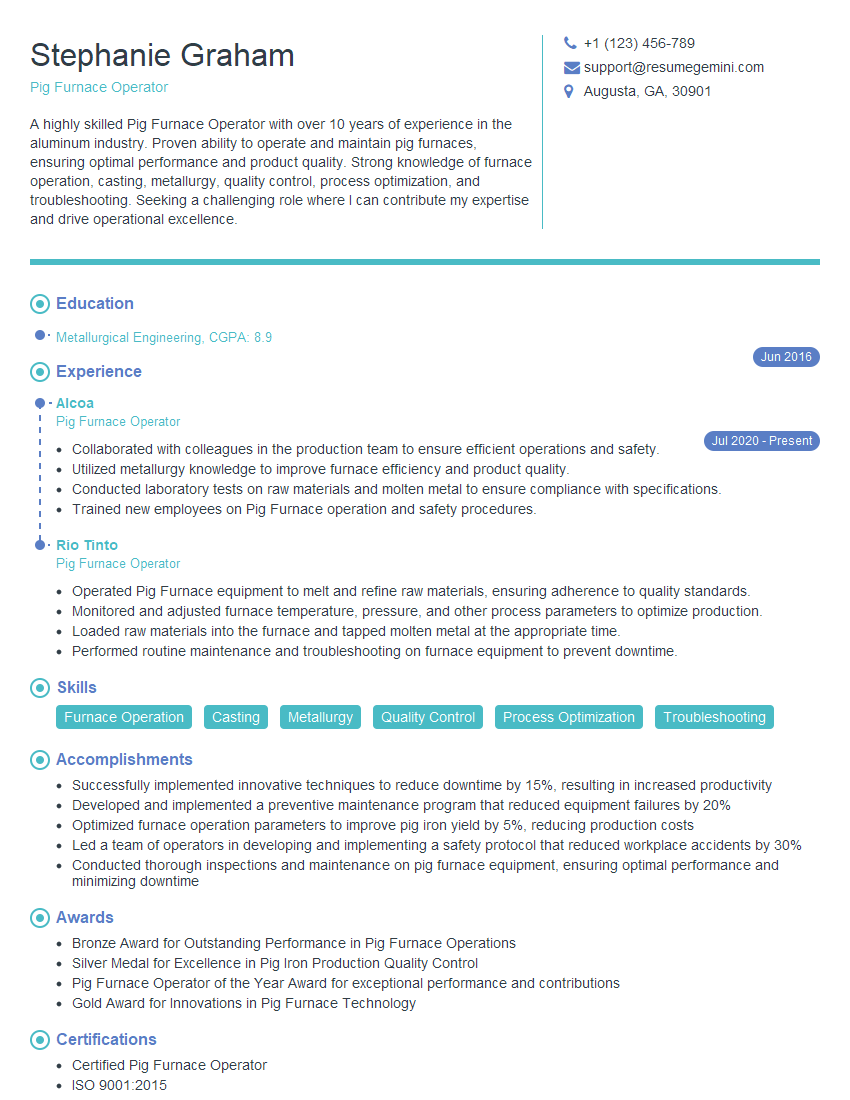

Stephanie Graham

Pig Furnace Operator

Summary

A highly skilled Pig Furnace Operator with over 10 years of experience in the aluminum industry. Proven ability to operate and maintain pig furnaces, ensuring optimal performance and product quality. Strong knowledge of furnace operation, casting, metallurgy, quality control, process optimization, and troubleshooting. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Metallurgical Engineering

June 2016

Skills

- Furnace Operation

- Casting

- Metallurgy

- Quality Control

- Process Optimization

- Troubleshooting

Work Experience

Pig Furnace Operator

- Collaborated with colleagues in the production team to ensure efficient operations and safety.

- Utilized metallurgy knowledge to improve furnace efficiency and product quality.

- Conducted laboratory tests on raw materials and molten metal to ensure compliance with specifications.

- Trained new employees on Pig Furnace operation and safety procedures.

Pig Furnace Operator

- Operated Pig Furnace equipment to melt and refine raw materials, ensuring adherence to quality standards.

- Monitored and adjusted furnace temperature, pressure, and other process parameters to optimize production.

- Loaded raw materials into the furnace and tapped molten metal at the appropriate time.

- Performed routine maintenance and troubleshooting on furnace equipment to prevent downtime.

Accomplishments

- Successfully implemented innovative techniques to reduce downtime by 15%, resulting in increased productivity

- Developed and implemented a preventive maintenance program that reduced equipment failures by 20%

- Optimized furnace operation parameters to improve pig iron yield by 5%, reducing production costs

- Led a team of operators in developing and implementing a safety protocol that reduced workplace accidents by 30%

- Conducted thorough inspections and maintenance on pig furnace equipment, ensuring optimal performance and minimizing downtime

Awards

- Bronze Award for Outstanding Performance in Pig Furnace Operations

- Silver Medal for Excellence in Pig Iron Production Quality Control

- Pig Furnace Operator of the Year Award for exceptional performance and contributions

- Gold Award for Innovations in Pig Furnace Technology

Certificates

- Certified Pig Furnace Operator

- ISO 9001:2015

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pig Furnace Operator

- Highlight your technical skills and experience in furnace operation, casting, and metallurgy.

- Quantify your accomplishments whenever possible, using specific metrics and data.

- Showcase your problem-solving abilities and commitment to continuous improvement.

- Proofread your resume carefully before submitting it to ensure accuracy and professionalism.

Essential Experience Highlights for a Strong Pig Furnace Operator Resume

- Operate and monitor pig furnaces, ensuring adherence to operational parameters.

- Cast molten aluminum into pigs, maintaining quality standards and production targets.

- Conduct metallurgical tests and analyze results to optimize furnace performance.

- Implement process improvements to increase efficiency and reduce operating costs.

- Troubleshoot and resolve operational issues, ensuring smooth furnace operation.

- Maintain a safe and clean work environment, adhering to established health and safety protocols.

Frequently Asked Questions (FAQ’s) For Pig Furnace Operator

What is the role of a Pig Furnace Operator?

A Pig Furnace Operator is responsible for operating and maintaining pig furnaces, which are used to melt and cast molten aluminum into pigs. They ensure that the furnaces are operating efficiently and safely, and that the aluminum pigs produced meet the required quality standards.

What skills are required to be a successful Pig Furnace Operator?

To be a successful Pig Furnace Operator, you need to have a strong understanding of furnace operation, casting, metallurgy, quality control, and process optimization. You should also be proficient in troubleshooting and resolving operational issues.

What is the work environment of a Pig Furnace Operator like?

Pig Furnace Operators typically work in industrial settings, such as aluminum smelters or foundries. The work can be physically demanding and may involve exposure to heat, noise, and fumes.

What are the career prospects for Pig Furnace Operators?

Pig Furnace Operators with experience and expertise can advance to supervisory or management roles within the aluminum industry. They may also pursue further education to enhance their skills and knowledge.

What is the average salary for a Pig Furnace Operator?

The average salary for a Pig Furnace Operator can vary depending on experience, location, and industry. According to Indeed, the average salary for a Pig Furnace Operator in the United States is around $60,000 per year.

What are the benefits of being a Pig Furnace Operator?

Some of the benefits of being a Pig Furnace Operator include job security, competitive salaries, and opportunities for career advancement. Pig Furnace Operators also play an important role in the production of aluminum, which is a vital material used in various industries.