Are you a seasoned Pipe and Tank Fabricator seeking a new career path? Discover our professionally built Pipe and Tank Fabricator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

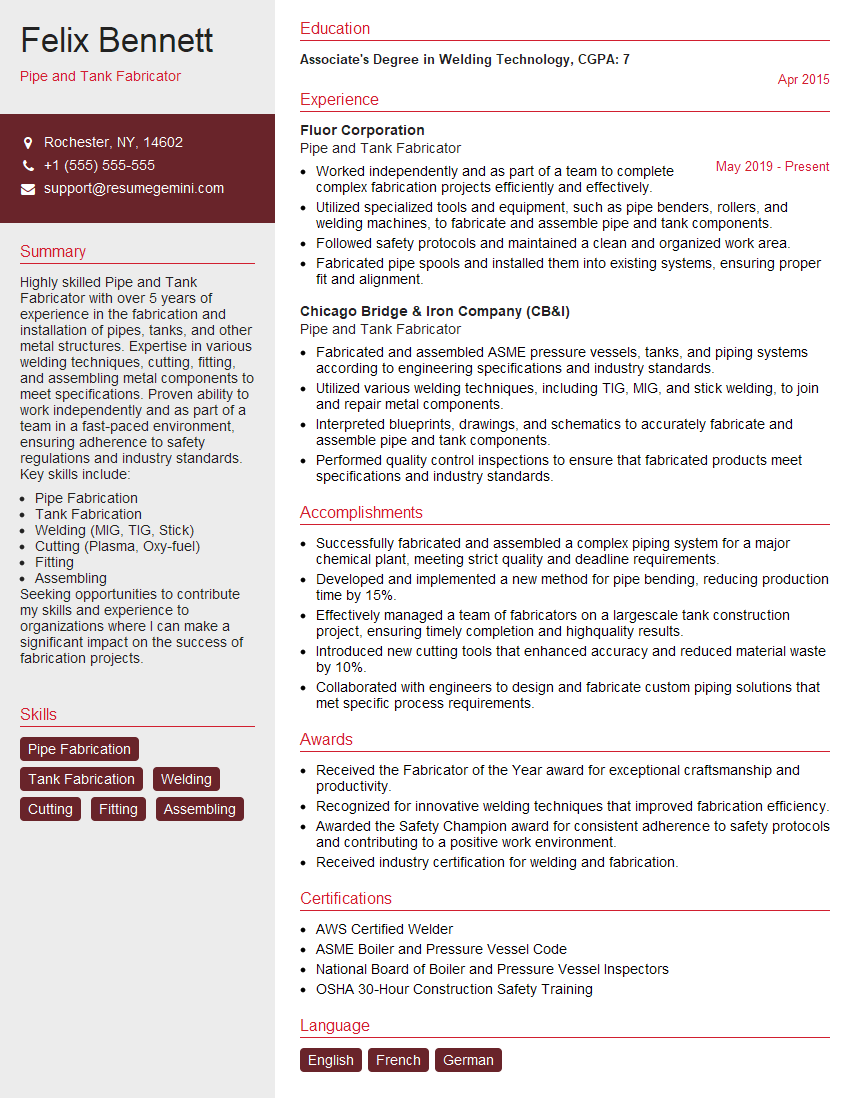

Felix Bennett

Pipe and Tank Fabricator

Summary

Highly skilled Pipe and Tank Fabricator with over 5 years of experience in the fabrication and installation of pipes, tanks, and other metal structures. Expertise in various welding techniques, cutting, fitting, and assembling metal components to meet specifications. Proven ability to work independently and as part of a team in a fast-paced environment, ensuring adherence to safety regulations and industry standards.

Key skills include:

- Pipe Fabrication

- Tank Fabrication

- Welding (MIG, TIG, Stick)

- Cutting (Plasma, Oxy-fuel)

- Fitting

- Assembling

Seeking opportunities to contribute my skills and experience to organizations where I can make a significant impact on the success of fabrication projects.

Education

Associate’s Degree in Welding Technology

April 2015

Skills

- Pipe Fabrication

- Tank Fabrication

- Welding

- Cutting

- Fitting

- Assembling

Work Experience

Pipe and Tank Fabricator

- Worked independently and as part of a team to complete complex fabrication projects efficiently and effectively.

- Utilized specialized tools and equipment, such as pipe benders, rollers, and welding machines, to fabricate and assemble pipe and tank components.

- Followed safety protocols and maintained a clean and organized work area.

- Fabricated pipe spools and installed them into existing systems, ensuring proper fit and alignment.

Pipe and Tank Fabricator

- Fabricated and assembled ASME pressure vessels, tanks, and piping systems according to engineering specifications and industry standards.

- Utilized various welding techniques, including TIG, MIG, and stick welding, to join and repair metal components.

- Interpreted blueprints, drawings, and schematics to accurately fabricate and assemble pipe and tank components.

- Performed quality control inspections to ensure that fabricated products meet specifications and industry standards.

Accomplishments

- Successfully fabricated and assembled a complex piping system for a major chemical plant, meeting strict quality and deadline requirements.

- Developed and implemented a new method for pipe bending, reducing production time by 15%.

- Effectively managed a team of fabricators on a largescale tank construction project, ensuring timely completion and highquality results.

- Introduced new cutting tools that enhanced accuracy and reduced material waste by 10%.

- Collaborated with engineers to design and fabricate custom piping solutions that met specific process requirements.

Awards

- Received the Fabricator of the Year award for exceptional craftsmanship and productivity.

- Recognized for innovative welding techniques that improved fabrication efficiency.

- Awarded the Safety Champion award for consistent adherence to safety protocols and contributing to a positive work environment.

- Received industry certification for welding and fabrication.

Certificates

- AWS Certified Welder

- ASME Boiler and Pressure Vessel Code

- National Board of Boiler and Pressure Vessel Inspectors

- OSHA 30-Hour Construction Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pipe and Tank Fabricator

- Highlight your welding certifications and any experience with specific welding codes.

- Emphasize your knowledge of fabrication processes, materials, and industry standards.

- Showcase your ability to work independently and as part of a team in a fast-paced environment.

- Provide specific examples of projects where you have successfully fabricated and installed pipes or tanks.

Essential Experience Highlights for a Strong Pipe and Tank Fabricator Resume

- Interpret blueprints, drawings, and specifications to determine fabrication requirements.

- Select and prepare appropriate materials, including pipes, fittings, and tanks.

- Use specialized tools and equipment to cut, shape, and weld metal components.

- Assemble and fit components to create pipes, tanks, and other structures.

- Test and inspect completed fabrications to ensure quality and compliance with standards.

- Maintain a clean and organized work area, adhering to safety regulations and industry best practices.

- Collaborate with engineers, other fabricators, and project managers to ensure project success.

Frequently Asked Questions (FAQ’s) For Pipe and Tank Fabricator

What are the educational requirements for a Pipe and Tank Fabricator?

Typically, employers prefer candidates with a high school diploma or equivalent, and an associate’s degree in welding technology or a related field is preferred.

What are the key skills required for a Pipe and Tank Fabricator?

Essential skills include proficiency in welding (MIG, TIG, stick), cutting (plasma, oxy-fuel), fitting, and assembling metal components. Knowledge of blueprint reading and interpretation is also important.

What are the career prospects for a Pipe and Tank Fabricator?

With experience and additional training, Pipe and Tank Fabricators can advance to supervisory roles, such as welding foreman or fabrication manager. Some may also start their own fabrication businesses.

What are the safety precautions that Pipe and Tank Fabricators must follow?

Fabricators must wear appropriate safety gear, including welding helmets, gloves, and protective clothing. They must also follow established safety procedures to prevent accidents, such as using proper ventilation and handling hazardous materials safely.

What is the work environment of a Pipe and Tank Fabricator like?

Fabricators typically work in workshops or fabrication plants, where they may be exposed to noise, fumes, and hazardous materials. They often work in teams and must be able to work independently and meet deadlines.

What are the industries that employ Pipe and Tank Fabricators?

Fabricators are employed in various industries, including construction, manufacturing, shipbuilding, and energy. They may work on projects such as pipelines, tanks, pressure vessels, and other metal structures.

Is certification required for Pipe and Tank Fabricators?

While not always required, obtaining welding certifications can enhance your credibility and demonstrate your skills. Relevant certifications include AWS Certified Welder and ASME Boiler and Pressure Vessel Code certifications.

What is the average salary for a Pipe and Tank Fabricator?

According to the U.S. Bureau of Labor Statistics, the median annual salary for Welders, Cutters, Solderers, and Brazers was $47,450 in May 2021. Salaries can vary based on experience, location, and industry.