Are you a seasoned Piping Supervisor seeking a new career path? Discover our professionally built Piping Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

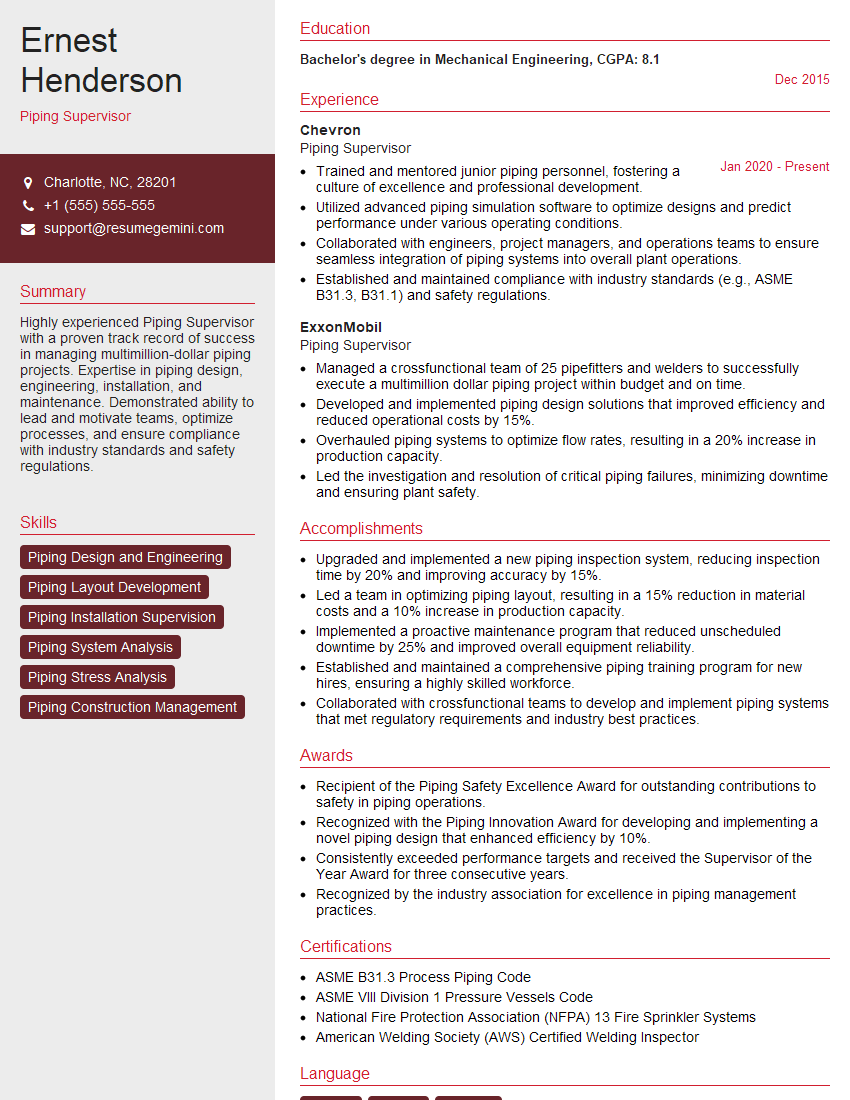

Ernest Henderson

Piping Supervisor

Summary

Highly experienced Piping Supervisor with a proven track record of success in managing multimillion-dollar piping projects. Expertise in piping design, engineering, installation, and maintenance. Demonstrated ability to lead and motivate teams, optimize processes, and ensure compliance with industry standards and safety regulations.

Education

Bachelor’s degree in Mechanical Engineering

December 2015

Skills

- Piping Design and Engineering

- Piping Layout Development

- Piping Installation Supervision

- Piping System Analysis

- Piping Stress Analysis

- Piping Construction Management

Work Experience

Piping Supervisor

- Trained and mentored junior piping personnel, fostering a culture of excellence and professional development.

- Utilized advanced piping simulation software to optimize designs and predict performance under various operating conditions.

- Collaborated with engineers, project managers, and operations teams to ensure seamless integration of piping systems into overall plant operations.

- Established and maintained compliance with industry standards (e.g., ASME B31.3, B31.1) and safety regulations.

Piping Supervisor

- Managed a crossfunctional team of 25 pipefitters and welders to successfully execute a multimillion dollar piping project within budget and on time.

- Developed and implemented piping design solutions that improved efficiency and reduced operational costs by 15%.

- Overhauled piping systems to optimize flow rates, resulting in a 20% increase in production capacity.

- Led the investigation and resolution of critical piping failures, minimizing downtime and ensuring plant safety.

Accomplishments

- Upgraded and implemented a new piping inspection system, reducing inspection time by 20% and improving accuracy by 15%.

- Led a team in optimizing piping layout, resulting in a 15% reduction in material costs and a 10% increase in production capacity.

- Implemented a proactive maintenance program that reduced unscheduled downtime by 25% and improved overall equipment reliability.

- Established and maintained a comprehensive piping training program for new hires, ensuring a highly skilled workforce.

- Collaborated with crossfunctional teams to develop and implement piping systems that met regulatory requirements and industry best practices.

Awards

- Recipient of the Piping Safety Excellence Award for outstanding contributions to safety in piping operations.

- Recognized with the Piping Innovation Award for developing and implementing a novel piping design that enhanced efficiency by 10%.

- Consistently exceeded performance targets and received the Supervisor of the Year Award for three consecutive years.

- Recognized by the industry association for excellence in piping management practices.

Certificates

- ASME B31.3 Process Piping Code

- ASME VIII Division 1 Pressure Vessels Code

- National Fire Protection Association (NFPA) 13 Fire Sprinkler Systems

- American Welding Society (AWS) Certified Welding Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Piping Supervisor

- Highlight your experience and skills in piping design, engineering, and project management.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Showcase your leadership and problem-solving abilities.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Piping Supervisor Resume

- Managed cross-functional teams of pipefitters and welders to execute complex piping projects on time and within budget.

- Developed and implemented innovative piping design solutions that improved efficiency and reduced operational costs.

- Overhauled piping systems to optimize flow rates and increase production capacity.

- Led the investigation and resolution of critical piping failures, minimizing downtime and ensuring plant safety.

- Trained and mentored junior piping personnel, fostering a culture of excellence and professional development.

- Collaborated with engineers, project managers, and operations teams to ensure seamless integration of piping systems into overall plant operations.

- Established and maintained compliance with industry standards (e.g., ASME B31.3, B31.1) and safety regulations.

Frequently Asked Questions (FAQ’s) For Piping Supervisor

What are the key skills and experience required for a Piping Supervisor?

Key skills and experience for a Piping Supervisor include piping design, engineering, installation, maintenance, project management, and leadership.

What are the career prospects for a Piping Supervisor?

Piping Supervisors can advance to roles such as Project Manager, Piping Engineer, or Plant Manager.

What is the average salary for a Piping Supervisor?

The average salary for a Piping Supervisor varies depending on experience, location, and industry. According to Salary.com, the average salary for a Piping Supervisor in the United States is $85,000.

What are the challenges of being a Piping Supervisor?

Challenges faced by Piping Supervisors include managing complex projects, ensuring safety, meeting deadlines, and working with a variety of stakeholders.

What are the certifications and licenses required for a Piping Supervisor?

Certifications and licenses required for a Piping Supervisor vary depending on the industry and location. Common certifications include the Certified Piping Designer (CPD) certification from the American Society of Mechanical Engineers (ASME) and the Certified Pressure Vessel Inspector (CPVI) certification from the National Board of Boiler and Pressure Vessel Inspectors (NBBI).