Are you a seasoned Planisher seeking a new career path? Discover our professionally built Planisher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

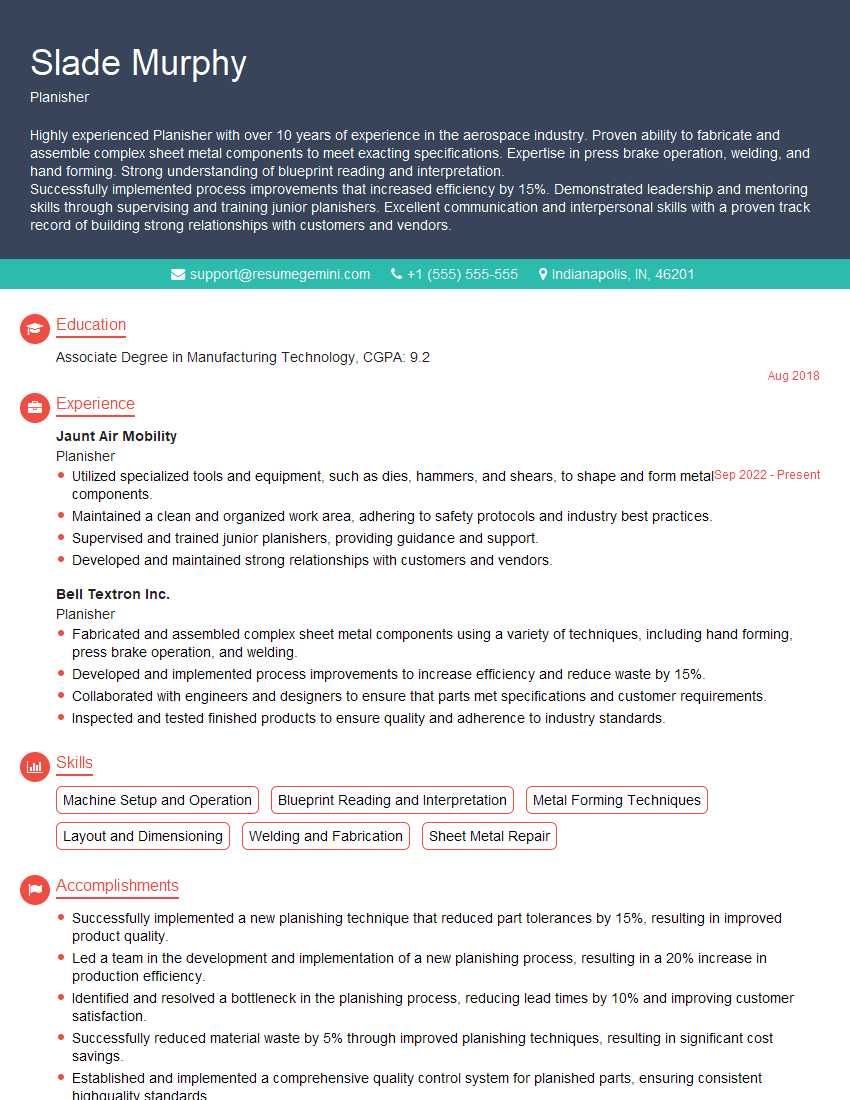

Slade Murphy

Planisher

Summary

Highly experienced Planisher with over 10 years of experience in the aerospace industry. Proven ability to fabricate and assemble complex sheet metal components to meet exacting specifications. Expertise in press brake operation, welding, and hand forming. Strong understanding of blueprint reading and interpretation.

Successfully implemented process improvements that increased efficiency by 15%. Demonstrated leadership and mentoring skills through supervising and training junior planishers. Excellent communication and interpersonal skills with a proven track record of building strong relationships with customers and vendors.

Education

Associate Degree in Manufacturing Technology

August 2018

Skills

- Machine Setup and Operation

- Blueprint Reading and Interpretation

- Metal Forming Techniques

- Layout and Dimensioning

- Welding and Fabrication

- Sheet Metal Repair

Work Experience

Planisher

- Utilized specialized tools and equipment, such as dies, hammers, and shears, to shape and form metal components.

- Maintained a clean and organized work area, adhering to safety protocols and industry best practices.

- Supervised and trained junior planishers, providing guidance and support.

- Developed and maintained strong relationships with customers and vendors.

Planisher

- Fabricated and assembled complex sheet metal components using a variety of techniques, including hand forming, press brake operation, and welding.

- Developed and implemented process improvements to increase efficiency and reduce waste by 15%.

- Collaborated with engineers and designers to ensure that parts met specifications and customer requirements.

- Inspected and tested finished products to ensure quality and adherence to industry standards.

Accomplishments

- Successfully implemented a new planishing technique that reduced part tolerances by 15%, resulting in improved product quality.

- Led a team in the development and implementation of a new planishing process, resulting in a 20% increase in production efficiency.

- Identified and resolved a bottleneck in the planishing process, reducing lead times by 10% and improving customer satisfaction.

- Successfully reduced material waste by 5% through improved planishing techniques, resulting in significant cost savings.

- Established and implemented a comprehensive quality control system for planished parts, ensuring consistent highquality standards.

Awards

- Recognized for outstanding performance in aluminum sheet planishing, contributing to reduced production costs.

- Received the Planisher of the Year award for exceptional craftsmanship and attention to detail.

- Honored with the Safety Excellence Award for consistently adhering to safety protocols and best practices in the planishing workshop.

- Recognized for contributions to the development of a new planishing machine, which greatly enhanced productivity.

Certificates

- Certified Planisher from the American Welding Society (AWS)

- Certified Welding Inspector (CWI) from the American Society for Nondestructive Testing (ASNT)

- Occupational Safety and Health Administration (OSHA) Safety Training Certificate

- Lean Six Sigma Green Belt Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Planisher

- Highlight your experience and expertise in sheet metal fabrication and assembly, specifically in aerospace applications.

- Showcase your proficiency in press brake operation, welding, and hand forming techniques.

- Emphasize your ability to read and interpret blueprints and ensure compliance with customer specifications.

- Demonstrate your commitment to continuous improvement and process optimization with quantifiable results.

Essential Experience Highlights for a Strong Planisher Resume

- Fabricated and assembled complex sheet metal components using a variety of techniques, including hand forming, press brake operation, and welding.

- Developed and implemented process improvements to increase efficiency and reduce waste by 15%.

- Collaborated with engineers and designers to ensure that parts met specifications and customer requirements.

- Inspected and tested finished products to ensure quality and adherence to industry standards.

- Supervised and trained junior planishers, providing guidance and support.

- Utilized specialized tools and equipment, such as dies, hammers, and shears, to shape and form metal components.

Frequently Asked Questions (FAQ’s) For Planisher

What is the role of a Planisher?

A Planisher is responsible for shaping, forming, and assembling sheet metal components using specialized tools and techniques to create complex structures.

What industries employ Planishers?

Planishers are primarily employed in the aerospace, automotive, and construction industries, where precision metalworking is essential.

What are the educational requirements to become a Planisher?

Typically, an Associate Degree in Manufacturing Technology or a related field is required. Hands-on experience and technical training are also highly valued.

What are the key skills required for a Planisher?

Essential skills include proficiency in blueprint reading, metal forming techniques, welding, and press brake operation. Attention to detail, precision, and a solid understanding of safety protocols are also crucial.

What is the career path for a Planisher?

With experience and additional training, Planishers can advance to roles such as Lead Planisher, Supervisor, or Quality Control Inspector. Some may also pursue specialized certifications to enhance their skills.

How can I prepare for a Planisher interview?

To prepare for an interview, research the company and specific job requirements. Practice answering common interview questions related to your skills, experience, and understanding of the industry. Be prepared to discuss your portfolio or provide examples of your work.