Are you a seasoned Planishing Hammer Operator seeking a new career path? Discover our professionally built Planishing Hammer Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

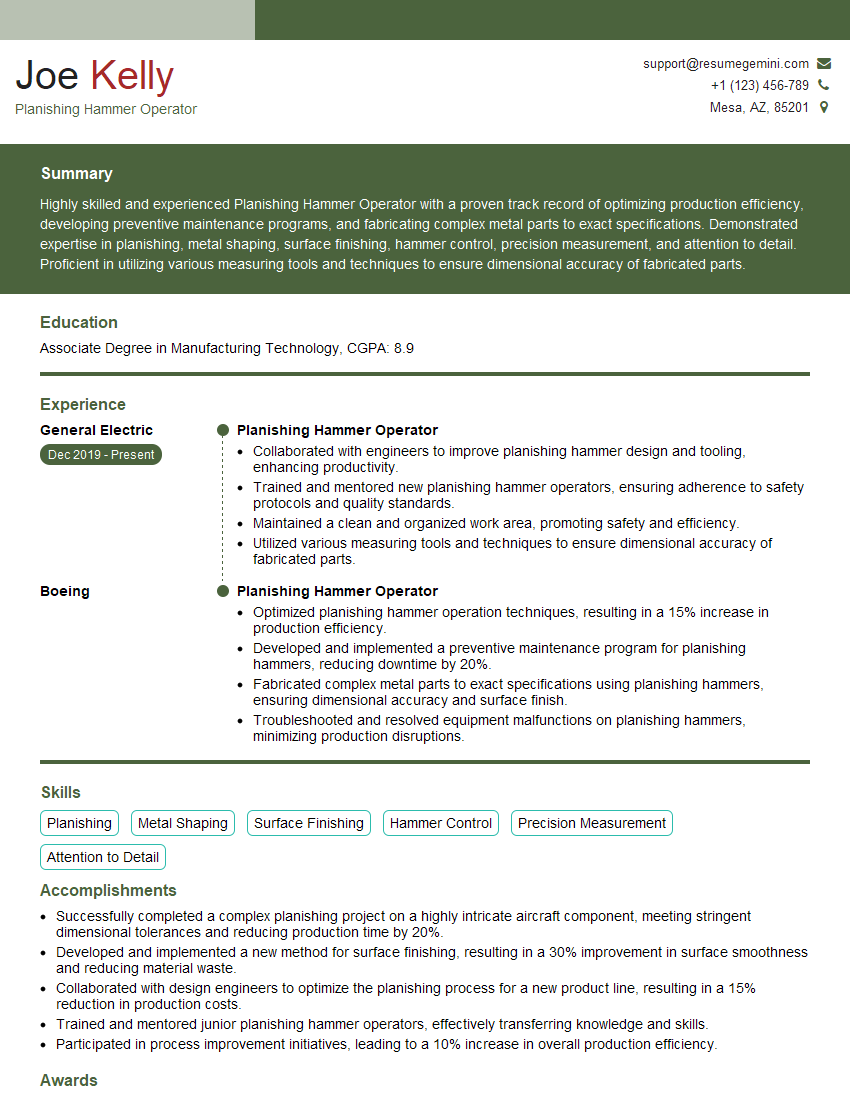

Joe Kelly

Planishing Hammer Operator

Summary

Highly skilled and experienced Planishing Hammer Operator with a proven track record of optimizing production efficiency, developing preventive maintenance programs, and fabricating complex metal parts to exact specifications. Demonstrated expertise in planishing, metal shaping, surface finishing, hammer control, precision measurement, and attention to detail. Proficient in utilizing various measuring tools and techniques to ensure dimensional accuracy of fabricated parts.

Education

Associate Degree in Manufacturing Technology

November 2015

Skills

- Planishing

- Metal Shaping

- Surface Finishing

- Hammer Control

- Precision Measurement

- Attention to Detail

Work Experience

Planishing Hammer Operator

- Collaborated with engineers to improve planishing hammer design and tooling, enhancing productivity.

- Trained and mentored new planishing hammer operators, ensuring adherence to safety protocols and quality standards.

- Maintained a clean and organized work area, promoting safety and efficiency.

- Utilized various measuring tools and techniques to ensure dimensional accuracy of fabricated parts.

Planishing Hammer Operator

- Optimized planishing hammer operation techniques, resulting in a 15% increase in production efficiency.

- Developed and implemented a preventive maintenance program for planishing hammers, reducing downtime by 20%.

- Fabricated complex metal parts to exact specifications using planishing hammers, ensuring dimensional accuracy and surface finish.

- Troubleshooted and resolved equipment malfunctions on planishing hammers, minimizing production disruptions.

Accomplishments

- Successfully completed a complex planishing project on a highly intricate aircraft component, meeting stringent dimensional tolerances and reducing production time by 20%.

- Developed and implemented a new method for surface finishing, resulting in a 30% improvement in surface smoothness and reducing material waste.

- Collaborated with design engineers to optimize the planishing process for a new product line, resulting in a 15% reduction in production costs.

- Trained and mentored junior planishing hammer operators, effectively transferring knowledge and skills.

- Participated in process improvement initiatives, leading to a 10% increase in overall production efficiency.

Awards

- Received the Outstanding Planishing Hammer Operator of the Year award for exceptional performance and contribution to the industry.

- Recognized with the Operational Excellence Award for consistently exceeding performance targets and implementing innovative techniques in planishing operations.

- Awarded the Safety Star recognition for maintaining an impeccable safety record and contributing to a positive work environment.

- Earned the Certified Planishing Hammer Operator designation from the American Welding Society.

Certificates

- OSHA 30-Hour Safety Training

- Certified Planishing Hammer Operator

- National Institute for Metalworking Skills (NIMS) Certification

- American Welding Society (AWS) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Planishing Hammer Operator

- Highlight your technical skills and experience in planishing, metal shaping, and surface finishing

- Quantify your accomplishments with specific metrics, such as increased production efficiency and reduced downtime

- Showcase your ability to troubleshoot and resolve equipment malfunctions

- Emphasize your attention to detail and commitment to quality

- Include relevant certifications or training programs that demonstrate your expertise

Essential Experience Highlights for a Strong Planishing Hammer Operator Resume

- Optimized planishing hammer operation techniques, resulting in a 15% increase in production efficiency

- Developed and implemented a preventive maintenance program for planishing hammers, reducing downtime by 20%

- Fabricated complex metal parts to exact specifications using planishing hammers, ensuring dimensional accuracy and surface finish

- Troubleshooted and resolved equipment malfunctions on planishing hammers, minimizing production disruptions

- Collaborated with engineers to improve planishing hammer design and tooling, enhancing productivity

- Trained and mentored new planishing hammer operators, ensuring adherence to safety protocols and quality standards

- Maintained a clean and organized work area, promoting safety and efficiency

Frequently Asked Questions (FAQ’s) For Planishing Hammer Operator

What is the role of a Planishing Hammer Operator?

A Planishing Hammer Operator uses specialized planishing hammers to shape and finish metal parts. They ensure the dimensional accuracy and surface finish of metal components, often working with engineers to improve production processes.

What skills are required for a Planishing Hammer Operator?

Planishing Hammer Operators typically possess strong technical skills in planishing, metal shaping, and surface finishing. They are also proficient in using precision measuring tools and techniques, and have a keen eye for detail.

What industries employ Planishing Hammer Operators?

Planishing Hammer Operators are employed in various industries, including aerospace, automotive, and manufacturing. They play a crucial role in producing high-quality metal components for a wide range of products.

What is the career path for a Planishing Hammer Operator?

Planishing Hammer Operators can advance their careers by becoming supervisors or managers in the manufacturing industry. They can also specialize in specific areas, such as metal finishing or quality control.

What are the salary expectations for a Planishing Hammer Operator?

The salary expectations for a Planishing Hammer Operator can vary depending on experience, industry, and location. According to Salary.com, the average salary for a Planishing Hammer Operator in the United States is around $45,000 per year.