Are you a seasoned Planishing Press Operator seeking a new career path? Discover our professionally built Planishing Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

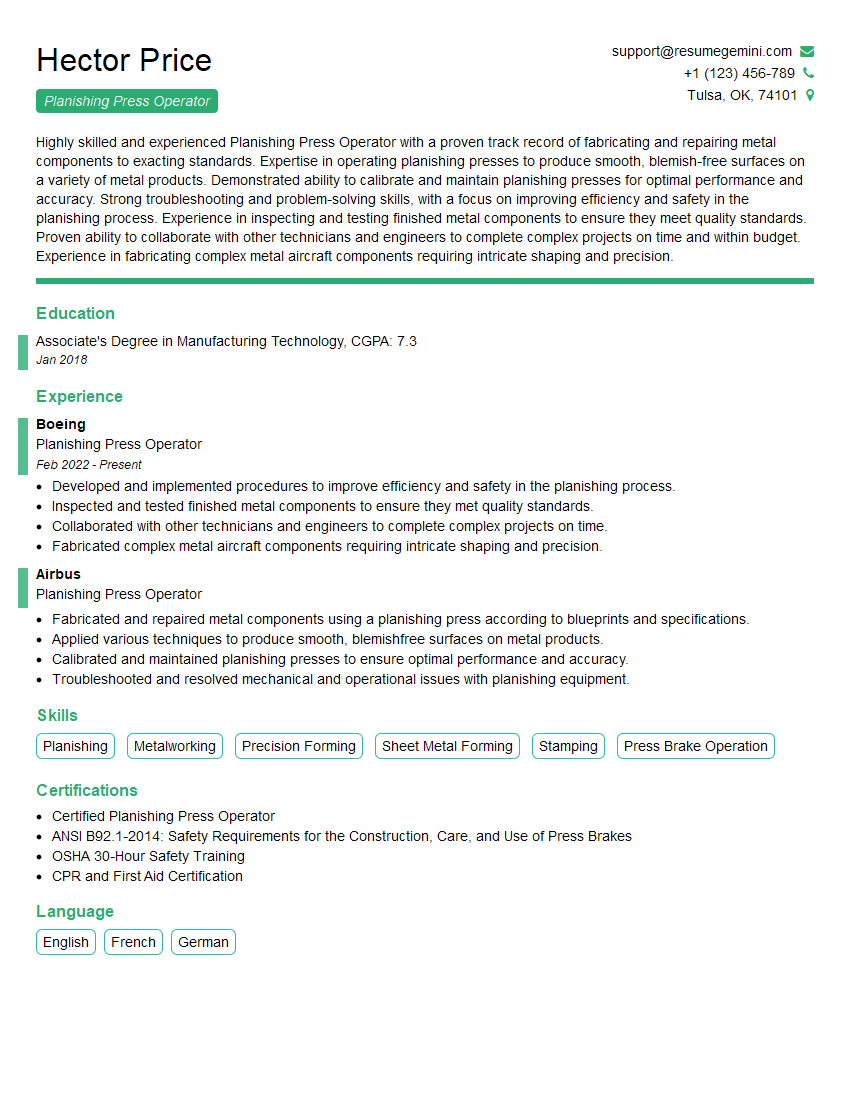

Hector Price

Planishing Press Operator

Summary

Highly skilled and experienced Planishing Press Operator with a proven track record of fabricating and repairing metal components to exacting standards. Expertise in operating planishing presses to produce smooth, blemish-free surfaces on a variety of metal products. Demonstrated ability to calibrate and maintain planishing presses for optimal performance and accuracy. Strong troubleshooting and problem-solving skills, with a focus on improving efficiency and safety in the planishing process. Experience in inspecting and testing finished metal components to ensure they meet quality standards. Proven ability to collaborate with other technicians and engineers to complete complex projects on time and within budget. Experience in fabricating complex metal aircraft components requiring intricate shaping and precision.

Education

Associate’s Degree in Manufacturing Technology

January 2018

Skills

- Planishing

- Metalworking

- Precision Forming

- Sheet Metal Forming

- Stamping

- Press Brake Operation

Work Experience

Planishing Press Operator

- Developed and implemented procedures to improve efficiency and safety in the planishing process.

- Inspected and tested finished metal components to ensure they met quality standards.

- Collaborated with other technicians and engineers to complete complex projects on time.

- Fabricated complex metal aircraft components requiring intricate shaping and precision.

Planishing Press Operator

- Fabricated and repaired metal components using a planishing press according to blueprints and specifications.

- Applied various techniques to produce smooth, blemishfree surfaces on metal products.

- Calibrated and maintained planishing presses to ensure optimal performance and accuracy.

- Troubleshooted and resolved mechanical and operational issues with planishing equipment.

Certificates

- Certified Planishing Press Operator

- ANSI B92.1-2014: Safety Requirements for the Construction, Care, and Use of Press Brakes

- OSHA 30-Hour Safety Training

- CPR and First Aid Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Planishing Press Operator

- Highlight your experience and skills in operating planishing presses to produce high-quality metal components.

- Showcase your ability to calibrate and maintain planishing presses for optimal performance and accuracy.

- Emphasize your troubleshooting and problem-solving skills, as well as your commitment to improving efficiency and safety.

- Include examples of complex projects you have worked on, demonstrating your ability to handle intricate shaping and precision.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the organization.

Essential Experience Highlights for a Strong Planishing Press Operator Resume

- Fabricated and repaired metal components using a planishing press according to blueprints and specifications.

- Applied various techniques to produce smooth, blemish-free surfaces on metal products.

- Calibrated and maintained planishing presses to ensure optimal performance and accuracy.

- Troubleshooted and resolved mechanical and operational issues with planishing equipment.

- Developed and implemented procedures to improve efficiency and safety in the planishing process.

- Inspected and tested finished metal components to ensure they met quality standards.

- Collaborated with other technicians and engineers to complete complex projects on time.

Frequently Asked Questions (FAQ’s) For Planishing Press Operator

What is the primary function of a Planishing Press Operator?

The primary function of a Planishing Press Operator is to fabricate and repair metal components using a planishing press, ensuring that the components meet the required specifications and quality standards.

What skills are required to be a successful Planishing Press Operator?

Successful Planishing Press Operators typically possess skills in planishing, metalworking, precision forming, sheet metal forming, stamping, and press brake operation.

What industries employ Planishing Press Operators?

Planishing Press Operators are employed in various industries, including aerospace, automotive, and manufacturing.

What is the average salary for a Planishing Press Operator?

The average salary for a Planishing Press Operator can vary depending on experience, location, and industry, but typically falls within a range.

What are the career advancement opportunities for a Planishing Press Operator?

Planishing Press Operators can advance their careers by becoming supervisors, quality control inspectors, or manufacturing engineers.

What are the challenges faced by Planishing Press Operators?

Planishing Press Operators may face challenges such as working with hazardous materials, operating heavy machinery, and meeting tight deadlines.

What is the job outlook for Planishing Press Operators?

The job outlook for Planishing Press Operators is expected to be stable, with a projected growth rate in line with the average for all occupations.