Are you a seasoned Plant Technical Specialist seeking a new career path? Discover our professionally built Plant Technical Specialist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

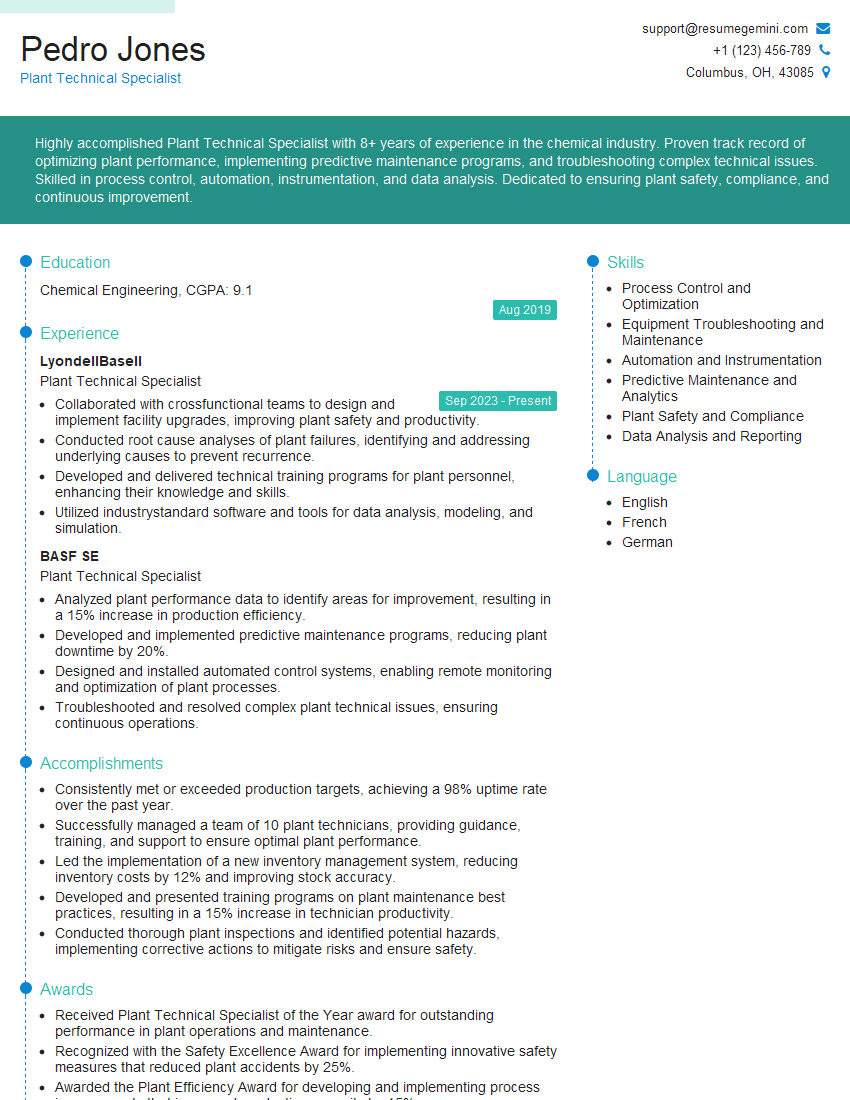

Pedro Jones

Plant Technical Specialist

Summary

Highly accomplished Plant Technical Specialist with 8+ years of experience in the chemical industry. Proven track record of optimizing plant performance, implementing predictive maintenance programs, and troubleshooting complex technical issues. Skilled in process control, automation, instrumentation, and data analysis. Dedicated to ensuring plant safety, compliance, and continuous improvement.

Education

Chemical Engineering

August 2019

Skills

- Process Control and Optimization

- Equipment Troubleshooting and Maintenance

- Automation and Instrumentation

- Predictive Maintenance and Analytics

- Plant Safety and Compliance

- Data Analysis and Reporting

Work Experience

Plant Technical Specialist

- Collaborated with crossfunctional teams to design and implement facility upgrades, improving plant safety and productivity.

- Conducted root cause analyses of plant failures, identifying and addressing underlying causes to prevent recurrence.

- Developed and delivered technical training programs for plant personnel, enhancing their knowledge and skills.

- Utilized industrystandard software and tools for data analysis, modeling, and simulation.

Plant Technical Specialist

- Analyzed plant performance data to identify areas for improvement, resulting in a 15% increase in production efficiency.

- Developed and implemented predictive maintenance programs, reducing plant downtime by 20%.

- Designed and installed automated control systems, enabling remote monitoring and optimization of plant processes.

- Troubleshooted and resolved complex plant technical issues, ensuring continuous operations.

Accomplishments

- Consistently met or exceeded production targets, achieving a 98% uptime rate over the past year.

- Successfully managed a team of 10 plant technicians, providing guidance, training, and support to ensure optimal plant performance.

- Led the implementation of a new inventory management system, reducing inventory costs by 12% and improving stock accuracy.

- Developed and presented training programs on plant maintenance best practices, resulting in a 15% increase in technician productivity.

- Conducted thorough plant inspections and identified potential hazards, implementing corrective actions to mitigate risks and ensure safety.

Awards

- Received Plant Technical Specialist of the Year award for outstanding performance in plant operations and maintenance.

- Recognized with the Safety Excellence Award for implementing innovative safety measures that reduced plant accidents by 25%.

- Awarded the Plant Efficiency Award for developing and implementing process improvements that increased production capacity by 15%.

- Won the Excellence in Plant Maintenance Award for outstanding contributions to improving plant reliability and efficiency.

Certificates

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Plant Engineer (CPE)

- ISA Certified Automation Professional (CAP)

- Certified Measurement and Control Technician (CMCT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plant Technical Specialist

- Quantify your accomplishments with specific metrics and results whenever possible.

- Highlight your expertise in industry-standard software and tools for data analysis, modeling, and simulation.

- Demonstrate your commitment to continuous learning and professional development.

- Showcase your ability to work effectively in a team environment and collaborate with cross-functional disciplines.

Essential Experience Highlights for a Strong Plant Technical Specialist Resume

- Analyze plant performance data to identify areas for improvement and implement solutions to increase efficiency and productivity

- Develop and execute predictive maintenance programs to minimize downtime and ensure smooth plant operations

- Design, install, and maintain automated control systems for remote monitoring and optimization of plant processes

- Troubleshoot and resolve complex technical issues to ensure uninterrupted operations and prevent costly breakdowns

- Collaborate with cross-functional teams to design and implement facility upgrades that enhance safety, productivity, and compliance

- Conduct root cause analyses of plant failures to identify underlying causes and prevent recurrence

- Develop and deliver technical training programs to enhance the knowledge and skills of plant personnel

Frequently Asked Questions (FAQ’s) For Plant Technical Specialist

What is the role of a Plant Technical Specialist?

A Plant Technical Specialist is responsible for ensuring the efficient and safe operation of a manufacturing plant. They analyze plant performance data, develop and implement predictive maintenance programs, design and install automated control systems, troubleshoot and resolve complex technical issues, and collaborate with cross-functional teams to design and implement facility upgrades.

What are the qualifications for a Plant Technical Specialist?

A Plant Technical Specialist typically holds a bachelor’s degree in chemical engineering or a related field, and possesses a strong understanding of process control, automation, instrumentation, and data analysis. They should also have experience in troubleshooting and resolving complex technical issues, and be able to work effectively in a team environment.

What are the key skills for a Plant Technical Specialist?

The key skills for a Plant Technical Specialist include process control and optimization, equipment troubleshooting and maintenance, automation and instrumentation, predictive maintenance and analytics, plant safety and compliance, and data analysis and reporting.

What is the career path for a Plant Technical Specialist?

The career path for a Plant Technical Specialist typically involves progression to roles with increasing responsibility, such as Plant Engineer, Production Manager, or Operations Manager. With additional experience and education, they may also move into management or consulting roles.

What is the salary range for a Plant Technical Specialist?

The salary range for a Plant Technical Specialist varies depending on experience, location, and industry. According to Salary.com, the median salary for a Plant Technical Specialist in the United States is around $95,000 per year.

What are the job prospects for a Plant Technical Specialist?

The job prospects for a Plant Technical Specialist are expected to be good over the next several years. The increasing demand for automated and efficient manufacturing processes is driving the need for skilled professionals in this field.

How can I become a Plant Technical Specialist?

To become a Plant Technical Specialist, you typically need to earn a bachelor’s degree in chemical engineering or a related field, and gain experience in process control, automation, instrumentation, and data analysis. You can also pursue professional development opportunities, such as certifications and training programs, to enhance your skills and knowledge.

What are the challenges of being a Plant Technical Specialist?

The challenges of being a Plant Technical Specialist include working in a fast-paced and demanding environment, dealing with complex technical issues, and ensuring the safety and reliability of plant operations. They may also need to work irregular hours and be on call for emergencies.