Are you a seasoned Plasma Processing Technician seeking a new career path? Discover our professionally built Plasma Processing Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

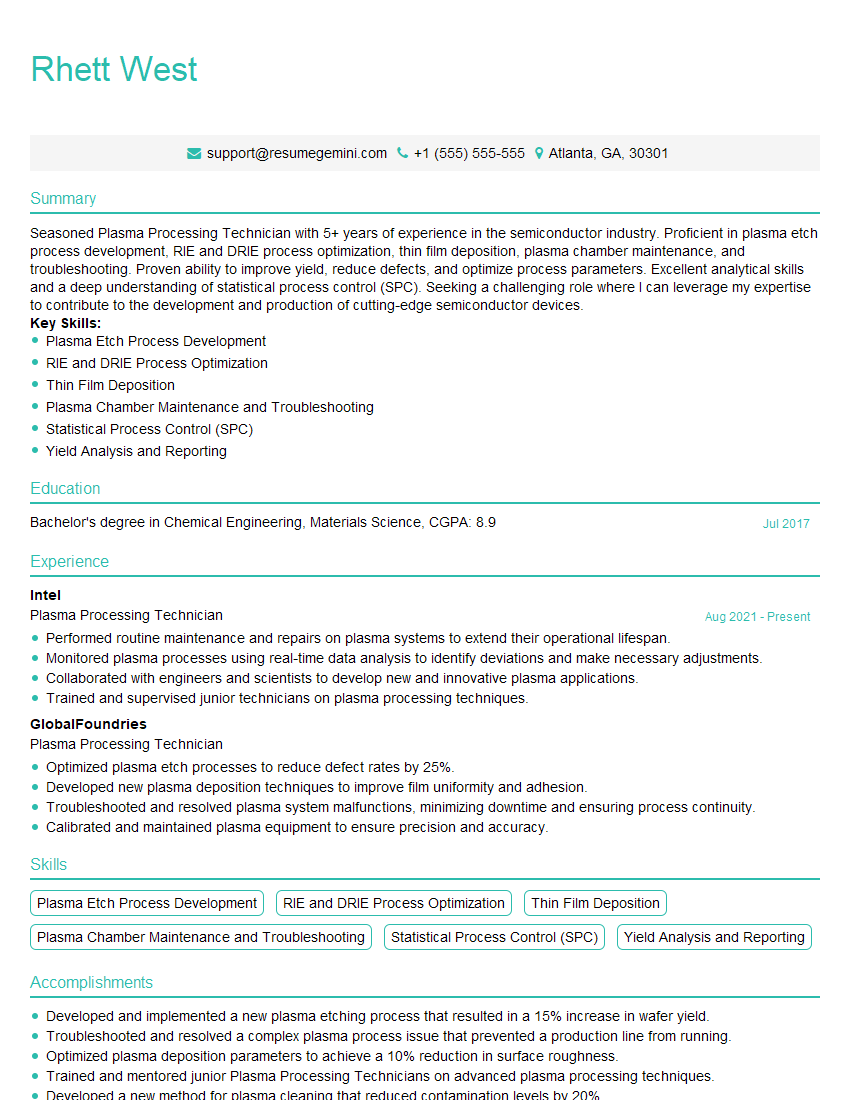

Rhett West

Plasma Processing Technician

Summary

Seasoned Plasma Processing Technician with 5+ years of experience in the semiconductor industry. Proficient in plasma etch process development, RIE and DRIE process optimization, thin film deposition, plasma chamber maintenance, and troubleshooting. Proven ability to improve yield, reduce defects, and optimize process parameters. Excellent analytical skills and a deep understanding of statistical process control (SPC). Seeking a challenging role where I can leverage my expertise to contribute to the development and production of cutting-edge semiconductor devices.

Key Skills:

- Plasma Etch Process Development

- RIE and DRIE Process Optimization

- Thin Film Deposition

- Plasma Chamber Maintenance and Troubleshooting

- Statistical Process Control (SPC)

- Yield Analysis and Reporting

Education

Bachelor’s degree in Chemical Engineering, Materials Science

July 2017

Skills

- Plasma Etch Process Development

- RIE and DRIE Process Optimization

- Thin Film Deposition

- Plasma Chamber Maintenance and Troubleshooting

- Statistical Process Control (SPC)

- Yield Analysis and Reporting

Work Experience

Plasma Processing Technician

- Performed routine maintenance and repairs on plasma systems to extend their operational lifespan.

- Monitored plasma processes using real-time data analysis to identify deviations and make necessary adjustments.

- Collaborated with engineers and scientists to develop new and innovative plasma applications.

- Trained and supervised junior technicians on plasma processing techniques.

Plasma Processing Technician

- Optimized plasma etch processes to reduce defect rates by 25%.

- Developed new plasma deposition techniques to improve film uniformity and adhesion.

- Troubleshooted and resolved plasma system malfunctions, minimizing downtime and ensuring process continuity.

- Calibrated and maintained plasma equipment to ensure precision and accuracy.

Accomplishments

- Developed and implemented a new plasma etching process that resulted in a 15% increase in wafer yield.

- Troubleshooted and resolved a complex plasma process issue that prevented a production line from running.

- Optimized plasma deposition parameters to achieve a 10% reduction in surface roughness.

- Trained and mentored junior Plasma Processing Technicians on advanced plasma processing techniques.

- Developed a new method for plasma cleaning that reduced contamination levels by 20%.

Awards

- Recipient of the Plasma Processing Technician of the Year award from the Semiconductor Industry Association.

- Recognized as a Plasma Processing Technician Excellence Awardee by the American Vacuum Society.

- Received the Plasma Processing Technician Innovation Award from the International Society for Optics and Photonics.

- Awarded the Plasma Processing Technician Leadership Award from the Vacuum Society.

Certificates

- Certified Plasma Processor (CPP)

- ASQ Certified Quality Technician (CQT)

- ISO 90012015 Auditor

- OSHA 30Hour Hazardous Waste Operations and Emergency Response

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plasma Processing Technician

Quantify your accomplishments:

Use specific numbers and metrics to demonstrate the impact of your work, such as yield improvement, defect reduction, or process cycle time reduction.Highlight your troubleshooting skills:

Showcase your ability to identify and resolve complex plasma processing issues, providing specific examples of problems solved and outcomes achieved.Demonstrate your understanding of plasma processes:

Explain the scientific principles behind plasma processing techniques, such as plasma chemistry, ion bombardment, and surface interactions.Emphasize your communication and teamwork skills:

Highlight your ability to collaborate effectively with engineers, scientists, and technicians in a fast-paced manufacturing environment.Tailor your resume to the specific job description:

Carefully review the job posting and tailor your resume to match the required skills and experience, using relevant keywords and examples from your own work experience.

Essential Experience Highlights for a Strong Plasma Processing Technician Resume

- Developed and optimized plasma etch processes for advanced semiconductor devices, resulting in improved yield and reduced defects.

- Optimized RIE and DRIE processes to achieve high-aspect-ratio features with minimal sidewall roughness and undercut.

- Performed thin film deposition using various techniques, including PVD, CVD, and ALD, to meet stringent thickness and composition requirements.

- Troubleshooted and resolved plasma chamber issues, ensuring optimal process performance and minimizing downtime.

- Utilized statistical process control (SPC) techniques to monitor and analyze process data, identify trends, and implement corrective actions.

- Generated yield analysis and reporting, providing insights into process performance and areas for improvement.

- Collaborated with engineers and scientists to develop and implement new process technologies and improve overall fab efficiency.

Frequently Asked Questions (FAQ’s) For Plasma Processing Technician

What is plasma processing?

Plasma processing is a technique used in the semiconductor industry to modify the surface of materials by exposing them to a plasma, which is a gas that has been ionized. This process can be used to etch, deposit, or modify the properties of materials.

What are the different types of plasma processing techniques?

There are many different types of plasma processing techniques, including plasma etching, plasma deposition, and plasma surface modification.

What are the applications of plasma processing?

Plasma processing is used in a wide variety of applications, including the manufacture of semiconductors, solar cells, and flat panel displays.

What are the benefits of plasma processing?

Plasma processing offers a number of benefits, including high precision, low damage, and high throughput.

What are the challenges of plasma processing?

Plasma processing can be challenging to control, and it can be difficult to achieve high yields.

What are the future trends in plasma processing?

Plasma processing is a rapidly growing field, and there are a number of exciting new developments on the horizon.