Are you a seasoned Plastic CNC Machine Operator seeking a new career path? Discover our professionally built Plastic CNC Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

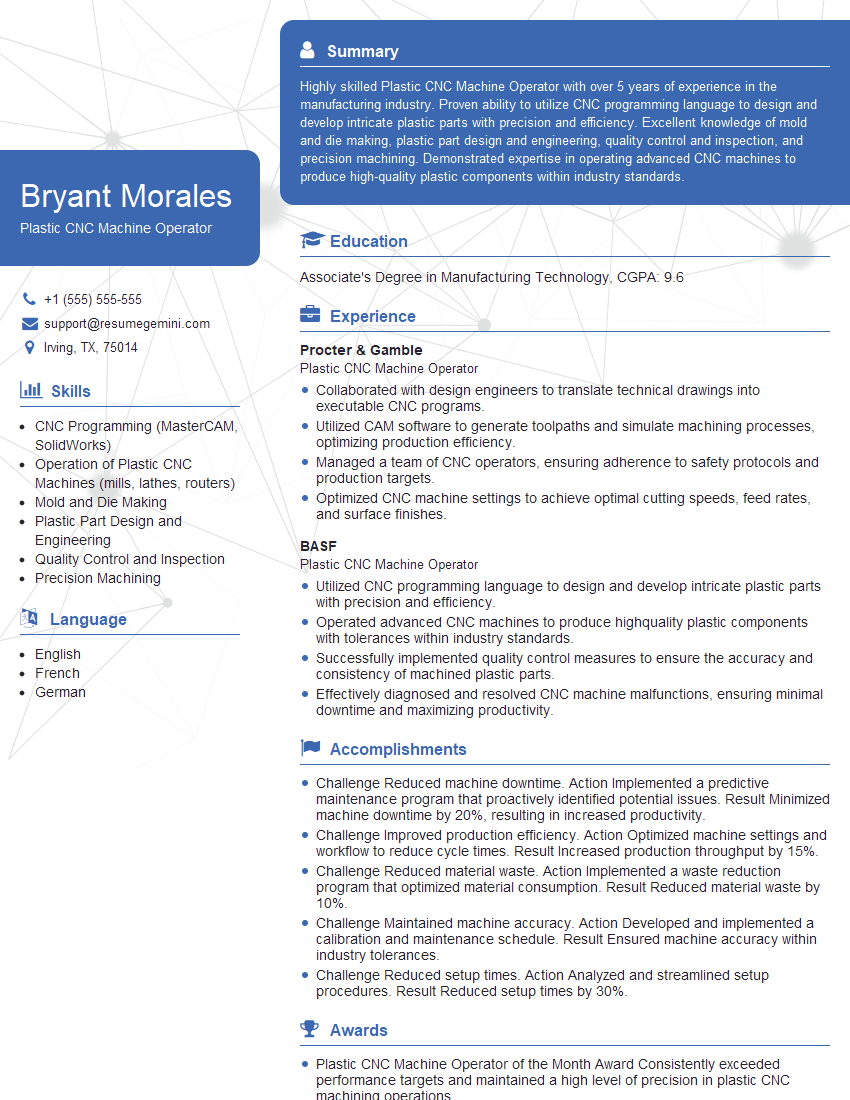

Bryant Morales

Plastic CNC Machine Operator

Summary

Highly skilled Plastic CNC Machine Operator with over 5 years of experience in the manufacturing industry. Proven ability to utilize CNC programming language to design and develop intricate plastic parts with precision and efficiency. Excellent knowledge of mold and die making, plastic part design and engineering, quality control and inspection, and precision machining. Demonstrated expertise in operating advanced CNC machines to produce high-quality plastic components within industry standards.

Education

Associate’s Degree in Manufacturing Technology

March 2015

Skills

- CNC Programming (MasterCAM, SolidWorks)

- Operation of Plastic CNC Machines (mills, lathes, routers)

- Mold and Die Making

- Plastic Part Design and Engineering

- Quality Control and Inspection

- Precision Machining

Work Experience

Plastic CNC Machine Operator

- Collaborated with design engineers to translate technical drawings into executable CNC programs.

- Utilized CAM software to generate toolpaths and simulate machining processes, optimizing production efficiency.

- Managed a team of CNC operators, ensuring adherence to safety protocols and production targets.

- Optimized CNC machine settings to achieve optimal cutting speeds, feed rates, and surface finishes.

Plastic CNC Machine Operator

- Utilized CNC programming language to design and develop intricate plastic parts with precision and efficiency.

- Operated advanced CNC machines to produce highquality plastic components with tolerances within industry standards.

- Successfully implemented quality control measures to ensure the accuracy and consistency of machined plastic parts.

- Effectively diagnosed and resolved CNC machine malfunctions, ensuring minimal downtime and maximizing productivity.

Accomplishments

- Challenge Reduced machine downtime. Action Implemented a predictive maintenance program that proactively identified potential issues. Result Minimized machine downtime by 20%, resulting in increased productivity.

- Challenge Improved production efficiency. Action Optimized machine settings and workflow to reduce cycle times. Result Increased production throughput by 15%.

- Challenge Reduced material waste. Action Implemented a waste reduction program that optimized material consumption. Result Reduced material waste by 10%.

- Challenge Maintained machine accuracy. Action Developed and implemented a calibration and maintenance schedule. Result Ensured machine accuracy within industry tolerances.

- Challenge Reduced setup times. Action Analyzed and streamlined setup procedures. Result Reduced setup times by 30%.

Awards

- Plastic CNC Machine Operator of the Month Award Consistently exceeded performance targets and maintained a high level of precision in plastic CNC machining operations.

- Safety Excellence Award Recognized for exceptional adherence to safety protocols and contributions to maintaining a safe work environment.

- Plastic CNC Innovation Award Acknowledged for developing and implementing a new technique that significantly improved the surface finish of machined plastic parts.

- Customer Service Excellence Award Commended for consistently exceeding customer expectations in terms of product quality and timely delivery.

Certificates

- Certified Plastic Part Design Engineer (CPPDE)

- CNC Machinist Certification

- ISO 9001 Auditor Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic CNC Machine Operator

- Showcase your expertise in CNC programming languages (MasterCAM, SolidWorks) and plastic part design and engineering.

- Highlight your experience in operating advanced CNC machines and your ability to produce high-quality plastic components within industry standards.

- Emphasize your skills in quality control and inspection, ensuring the accuracy and consistency of machined plastic parts.

- Demonstrate your ability to effectively diagnose and resolve CNC machine malfunctions, ensuring minimal downtime and maximizing productivity.

- Quantify your accomplishments whenever possible to provide tangible evidence of your impact on the organization.

Essential Experience Highlights for a Strong Plastic CNC Machine Operator Resume

- Utilized CNC programming language (MasterCAM, SolidWorks) to design and develop intricate plastic parts with precision and efficiency.

- Collaborated with design engineers to translate technical drawings into executable CNC programs.

- Operated advanced CNC machines (mills, lathes, routers) to produce high-quality plastic components within industry standards.

- Optimized CNC machine settings to achieve optimal cutting speeds, feed rates, and surface finishes.

- Effectively diagnosed and resolved CNC machine malfunctions, ensuring minimal downtime and maximizing productivity.

- Successfully implemented quality control measures to ensure the accuracy and consistency of machined plastic parts.

- Managed a team of CNC operators, ensuring adherence to safety protocols and production targets.

Frequently Asked Questions (FAQ’s) For Plastic CNC Machine Operator

What are the key skills required to be a successful Plastic CNC Machine Operator?

The key skills required for a successful Plastic CNC Machine Operator include CNC programming (MasterCAM, SolidWorks), operating Plastic CNC Machines (mills, lathes, routers), mold and die making, plastic part design and engineering, quality control and inspection, and precision machining.

What are the major responsibilities of a Plastic CNC Machine Operator?

The major responsibilities of a Plastic CNC Machine Operator include using CNC programming language to design and develop intricate plastic parts, operating advanced CNC machines to produce high-quality plastic components, implementing quality control measures, diagnosing and resolving CNC machine malfunctions, and collaborating with design engineers.

What are the career prospects for a Plastic CNC Machine Operator?

The career prospects for a Plastic CNC Machine Operator are positive, with a projected 10% growth in employment over the next decade. As the manufacturing industry continues to adopt automation, skilled CNC Machine Operators will be in high demand.

What are the educational requirements for a Plastic CNC Machine Operator?

Most Plastic CNC Machine Operators have an Associate’s Degree in Manufacturing Technology or a related field. However, some employers may only require a high school diploma or equivalent.

What are the salary expectations for a Plastic CNC Machine Operator?

The salary expectations for a Plastic CNC Machine Operator vary depending on experience, location, and company size. According to Indeed, the average salary for a Plastic CNC Machine Operator in the United States is around $25 per hour.

What is the work environment of a Plastic CNC Machine Operator?

Plastic CNC Machine Operators typically work in manufacturing facilities, operating CNC machines in a production environment. The work can be physically demanding, as it requires standing for long periods and lifting heavy objects.

Are there any certifications available for Plastic CNC Machine Operators?

Yes, there are several certifications available for Plastic CNC Machine Operators, including the Certified Plastic Part Designer (CPPD) certification from the Society of Plastics Engineers (SPE) and the CNC Programmer/Operator (CNCPO) certification from the National Institute for Metalworking Skills (NIMS).