Are you a seasoned Plastic Joint Maker seeking a new career path? Discover our professionally built Plastic Joint Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

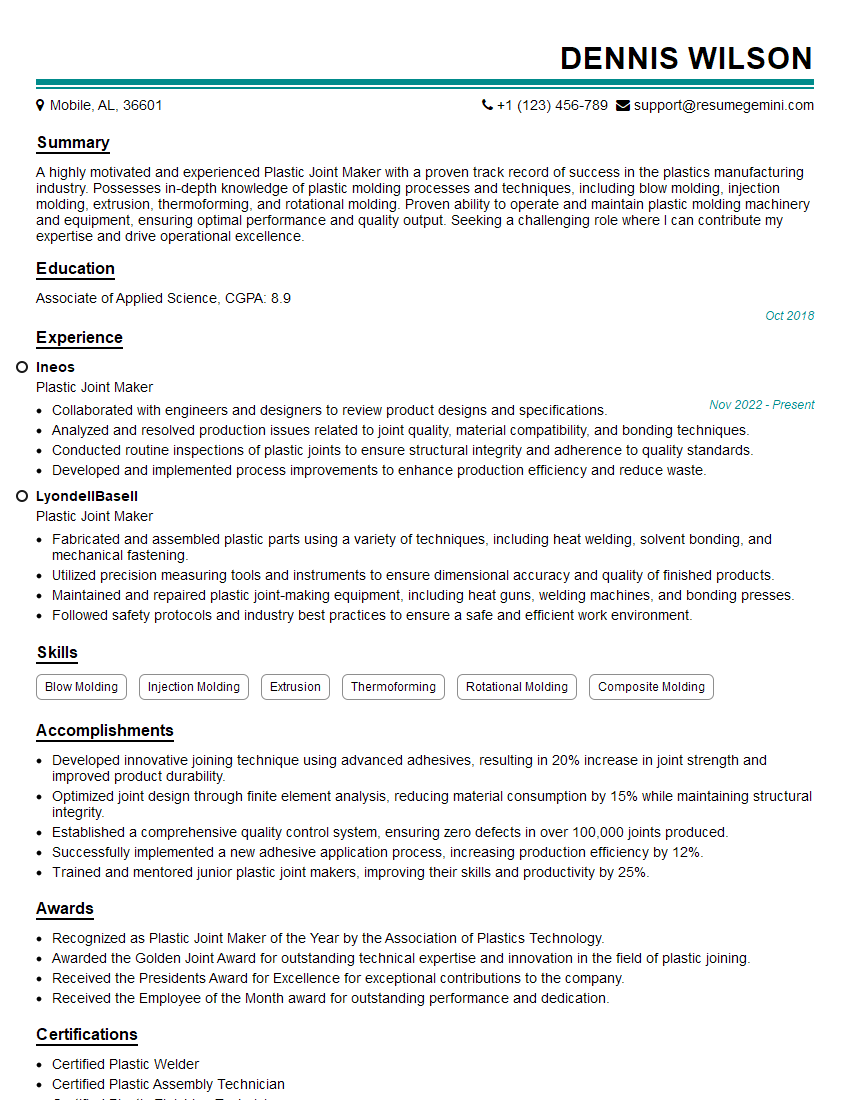

Dennis Wilson

Plastic Joint Maker

Summary

A highly motivated and experienced Plastic Joint Maker with a proven track record of success in the plastics manufacturing industry. Possesses in-depth knowledge of plastic molding processes and techniques, including blow molding, injection molding, extrusion, thermoforming, and rotational molding. Proven ability to operate and maintain plastic molding machinery and equipment, ensuring optimal performance and quality output. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Associate of Applied Science

October 2018

Skills

- Blow Molding

- Injection Molding

- Extrusion

- Thermoforming

- Rotational Molding

- Composite Molding

Work Experience

Plastic Joint Maker

- Collaborated with engineers and designers to review product designs and specifications.

- Analyzed and resolved production issues related to joint quality, material compatibility, and bonding techniques.

- Conducted routine inspections of plastic joints to ensure structural integrity and adherence to quality standards.

- Developed and implemented process improvements to enhance production efficiency and reduce waste.

Plastic Joint Maker

- Fabricated and assembled plastic parts using a variety of techniques, including heat welding, solvent bonding, and mechanical fastening.

- Utilized precision measuring tools and instruments to ensure dimensional accuracy and quality of finished products.

- Maintained and repaired plastic joint-making equipment, including heat guns, welding machines, and bonding presses.

- Followed safety protocols and industry best practices to ensure a safe and efficient work environment.

Accomplishments

- Developed innovative joining technique using advanced adhesives, resulting in 20% increase in joint strength and improved product durability.

- Optimized joint design through finite element analysis, reducing material consumption by 15% while maintaining structural integrity.

- Established a comprehensive quality control system, ensuring zero defects in over 100,000 joints produced.

- Successfully implemented a new adhesive application process, increasing production efficiency by 12%.

- Trained and mentored junior plastic joint makers, improving their skills and productivity by 25%.

Awards

- Recognized as Plastic Joint Maker of the Year by the Association of Plastics Technology.

- Awarded the Golden Joint Award for outstanding technical expertise and innovation in the field of plastic joining.

- Received the Presidents Award for Excellence for exceptional contributions to the company.

- Received the Employee of the Month award for outstanding performance and dedication.

Certificates

- Certified Plastic Welder

- Certified Plastic Assembly Technician

- Certified Plastic Finishing Technician

- Certified Plastic Testing Technician

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Joint Maker

- Highlight your skills and experience in plastic molding processes, such as blow molding, injection molding, extrusion, thermoforming, and rotational molding.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the organization.

- Showcase your knowledge of plastic materials and their properties, as well as your ability to identify and resolve molding issues.

- Emphasize your attention to detail, quality assurance, and commitment to safety.

Essential Experience Highlights for a Strong Plastic Joint Maker Resume

- Operate and maintain plastic molding machinery, including blow molding machines, injection molding machines, extruders, thermoforming machines, and rotational molding machines

- Set up and adjust molding parameters to meet product specifications and ensure quality output

- Monitor and troubleshoot molding processes to identify and resolve issues promptly

- Inspect finished plastic products for defects and ensure compliance with quality standards

- Maintain a clean and organized work area, following safety protocols and industry best practices

- Collaborate with other team members to optimize production processes and enhance efficiency

Frequently Asked Questions (FAQ’s) For Plastic Joint Maker

What are the primary responsibilities of a Plastic Joint Maker?

The primary responsibilities of a Plastic Joint Maker include operating and maintaining plastic molding machinery, setting up and adjusting molding parameters, monitoring and troubleshooting molding processes, inspecting finished plastic products, and maintaining a clean and organized work area.

What are the key skills required to be successful as a Plastic Joint Maker?

Key skills for a successful Plastic Joint Maker include knowledge of plastic molding processes, experience operating and maintaining plastic molding machinery, ability to monitor and troubleshoot molding processes, attention to detail, and commitment to quality assurance.

What are the career prospects for Plastic Joint Makers?

Plastic Joint Makers with experience and expertise can advance to supervisory or management roles in the plastics manufacturing industry. They may also specialize in specific molding processes or work in research and development.

What is the work environment like for Plastic Joint Makers?

Plastic Joint Makers typically work in manufacturing facilities, operating and maintaining plastic molding machinery. The work environment can be noisy and involve exposure to chemicals and dust. Safety protocols and proper protective equipment are essential.

What are the educational requirements to become a Plastic Joint Maker?

While formal education requirements may vary, many Plastic Joint Makers have an Associate of Applied Science degree in a related field such as plastics technology or manufacturing engineering.

Is experience necessary to become a Plastic Joint Maker?

Yes, most Plastic Joint Makers have prior experience working in a manufacturing environment, particularly in plastics molding. Hands-on experience with plastic molding machinery and processes is typically required.

Are there any certifications or licenses required for Plastic Joint Makers?

While not always required, obtaining certifications in plastic molding processes or quality assurance can enhance a Plastic Joint Maker’s credibility and career prospects.