Are you a seasoned Plastic Shaper seeking a new career path? Discover our professionally built Plastic Shaper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

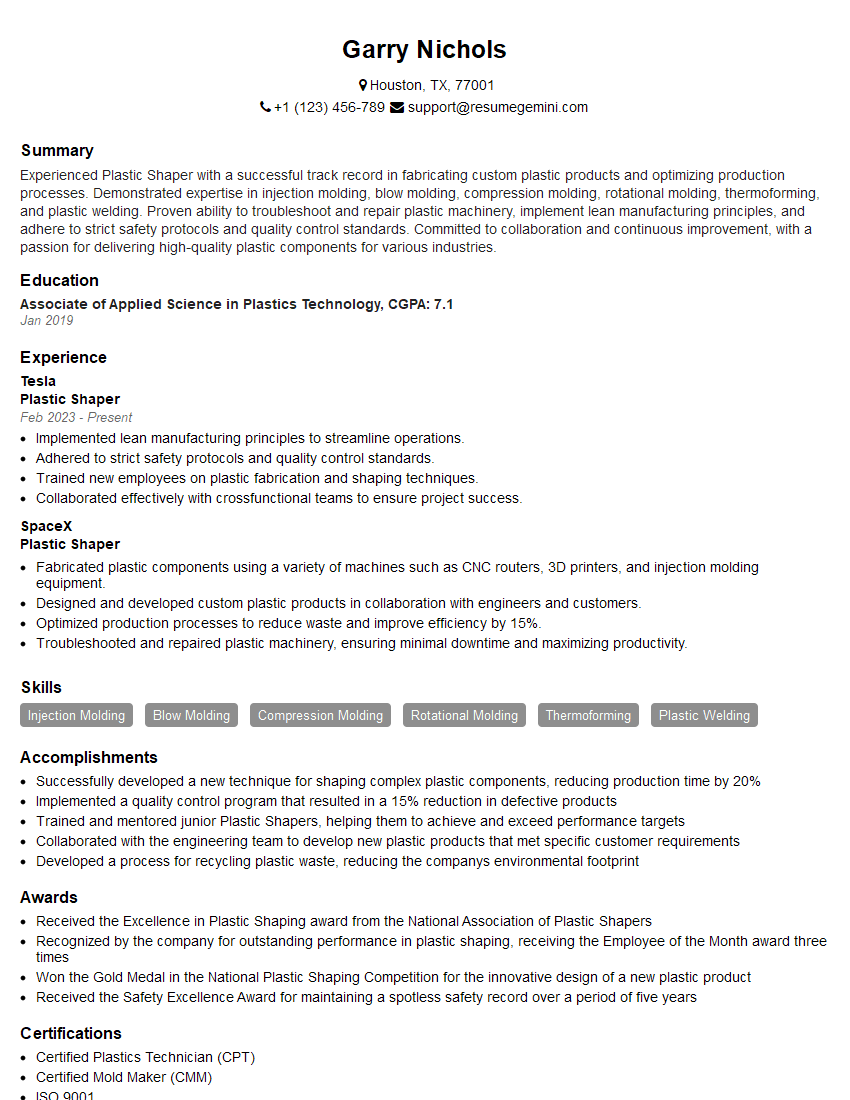

Garry Nichols

Plastic Shaper

Summary

Experienced Plastic Shaper with a successful track record in fabricating custom plastic products and optimizing production processes. Demonstrated expertise in injection molding, blow molding, compression molding, rotational molding, thermoforming, and plastic welding. Proven ability to troubleshoot and repair plastic machinery, implement lean manufacturing principles, and adhere to strict safety protocols and quality control standards. Committed to collaboration and continuous improvement, with a passion for delivering high-quality plastic components for various industries.

Education

Associate of Applied Science in Plastics Technology

January 2019

Skills

- Injection Molding

- Blow Molding

- Compression Molding

- Rotational Molding

- Thermoforming

- Plastic Welding

Work Experience

Plastic Shaper

- Implemented lean manufacturing principles to streamline operations.

- Adhered to strict safety protocols and quality control standards.

- Trained new employees on plastic fabrication and shaping techniques.

- Collaborated effectively with crossfunctional teams to ensure project success.

Plastic Shaper

- Fabricated plastic components using a variety of machines such as CNC routers, 3D printers, and injection molding equipment.

- Designed and developed custom plastic products in collaboration with engineers and customers.

- Optimized production processes to reduce waste and improve efficiency by 15%.

- Troubleshooted and repaired plastic machinery, ensuring minimal downtime and maximizing productivity.

Accomplishments

- Successfully developed a new technique for shaping complex plastic components, reducing production time by 20%

- Implemented a quality control program that resulted in a 15% reduction in defective products

- Trained and mentored junior Plastic Shapers, helping them to achieve and exceed performance targets

- Collaborated with the engineering team to develop new plastic products that met specific customer requirements

- Developed a process for recycling plastic waste, reducing the companys environmental footprint

Awards

- Received the Excellence in Plastic Shaping award from the National Association of Plastic Shapers

- Recognized by the company for outstanding performance in plastic shaping, receiving the Employee of the Month award three times

- Won the Gold Medal in the National Plastic Shaping Competition for the innovative design of a new plastic product

- Received the Safety Excellence Award for maintaining a spotless safety record over a period of five years

Certificates

- Certified Plastics Technician (CPT)

- Certified Mold Maker (CMM)

- ISO 9001

- IATF 16949

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Shaper

- Quantify your accomplishments with data and metrics to demonstrate the impact of your contributions.

- Highlight your proficiency in various plastic shaping techniques and machinery, including injection molding, blow molding, and thermoforming.

- Showcase your understanding of lean manufacturing principles and how you have implemented them to improve efficiency and reduce costs.

- Emphasize your ability to work collaboratively with cross-functional teams and contribute to project success.

Essential Experience Highlights for a Strong Plastic Shaper Resume

- Fabricated plastic components using advanced machinery, including CNC routers, 3D printers, and injection molding equipment.

- Designed and developed custom plastic products in collaboration with engineers and customer specifications.

- Optimized production processes to reduce waste and improve efficiency by 15%, resulting in increased profitability.

- Troubleshooted and repaired plastic machinery, ensuring minimal downtime and maximizing productivity.

- Implemented lean manufacturing principles to streamline operations, enhance productivity, and reduce waste.

- Adhered to strict safety protocols and quality control standards, ensuring compliance and product integrity.

- Trained new employees on plastic fabrication and shaping techniques, fostering a skilled workforce.

Frequently Asked Questions (FAQ’s) For Plastic Shaper

What are the essential skills required for a Plastic Shaper?

Essential skills include proficiency in injection molding, blow molding, compression molding, rotational molding, thermoforming, and plastic welding, as well as a strong understanding of plastic properties and manufacturing processes.

What industries are Plastic Shapers most in demand?

Plastic Shapers are in high demand in various industries, including automotive, aerospace, medical, and consumer products, where the production of plastic components is essential.

What are the career advancement opportunities for Plastic Shapers?

With experience and additional training, Plastic Shapers can advance to roles such as Production Supervisor, Quality Control Manager, or Engineering Technician.

What are the safety precautions that Plastic Shapers must follow?

Plastic Shapers must adhere to strict safety protocols, including proper handling of equipment, wearing appropriate protective gear, and following established safety procedures to minimize risks.

How can I improve my skills as a Plastic Shaper?

To enhance your skills, consider pursuing industry certifications, attending training workshops, staying updated on advancements in plastic shaping technologies, and actively seeking opportunities to expand your knowledge and experience.

What personal qualities are important for success as a Plastic Shaper?

Successful Plastic Shapers possess strong attention to detail, problem-solving abilities, manual dexterity, and a commitment to quality and safety.

What is the job outlook for Plastic Shapers?

The job outlook for Plastic Shapers is expected to be favorable, as the demand for plastic components continues to grow across various industries.

What is the salary range for Plastic Shapers?

The salary range for Plastic Shapers can vary depending on experience, location, and industry, but typically falls within the range of $25,000 to $50,000 annually.