Are you a seasoned Plastics Plater seeking a new career path? Discover our professionally built Plastics Plater Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

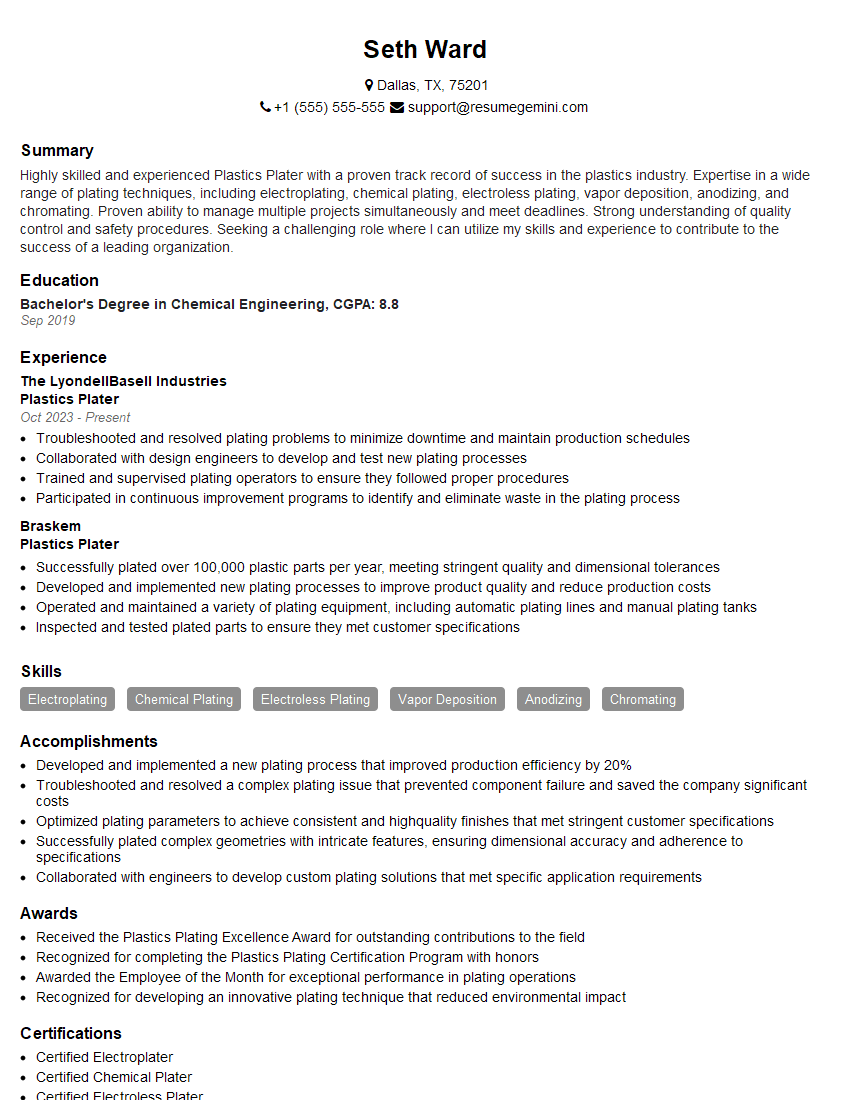

Seth Ward

Plastics Plater

Summary

Highly skilled and experienced Plastics Plater with a proven track record of success in the plastics industry. Expertise in a wide range of plating techniques, including electroplating, chemical plating, electroless plating, vapor deposition, anodizing, and chromating. Proven ability to manage multiple projects simultaneously and meet deadlines. Strong understanding of quality control and safety procedures. Seeking a challenging role where I can utilize my skills and experience to contribute to the success of a leading organization.

Education

Bachelor’s Degree in Chemical Engineering

September 2019

Skills

- Electroplating

- Chemical Plating

- Electroless Plating

- Vapor Deposition

- Anodizing

- Chromating

Work Experience

Plastics Plater

- Troubleshooted and resolved plating problems to minimize downtime and maintain production schedules

- Collaborated with design engineers to develop and test new plating processes

- Trained and supervised plating operators to ensure they followed proper procedures

- Participated in continuous improvement programs to identify and eliminate waste in the plating process

Plastics Plater

- Successfully plated over 100,000 plastic parts per year, meeting stringent quality and dimensional tolerances

- Developed and implemented new plating processes to improve product quality and reduce production costs

- Operated and maintained a variety of plating equipment, including automatic plating lines and manual plating tanks

- Inspected and tested plated parts to ensure they met customer specifications

Accomplishments

- Developed and implemented a new plating process that improved production efficiency by 20%

- Troubleshooted and resolved a complex plating issue that prevented component failure and saved the company significant costs

- Optimized plating parameters to achieve consistent and highquality finishes that met stringent customer specifications

- Successfully plated complex geometries with intricate features, ensuring dimensional accuracy and adherence to specifications

- Collaborated with engineers to develop custom plating solutions that met specific application requirements

Awards

- Received the Plastics Plating Excellence Award for outstanding contributions to the field

- Recognized for completing the Plastics Plating Certification Program with honors

- Awarded the Employee of the Month for exceptional performance in plating operations

- Recognized for developing an innovative plating technique that reduced environmental impact

Certificates

- Certified Electroplater

- Certified Chemical Plater

- Certified Electroless Plater

- Certified Vapor Deposition Technician

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastics Plater

- Highlight your relevant skills and experience in your resume.

- Use strong action verbs to describe your accomplishments.

- Quantify your results whenever possible.

- Proofread your resume carefully before submitting it.

- Tailor your resume to each job you apply for.

Essential Experience Highlights for a Strong Plastics Plater Resume

- Operate and maintain electroplating, chemical plating, electroless plating, vapor deposition, anodizing, and chromating equipment.

- Prepare and clean surfaces for plating.

- Apply coatings to plastics and other materials.

- Inspect and test plated surfaces to ensure quality.

- Troubleshoot and resolve plating problems.

- Maintain a clean and safe work environment.

Frequently Asked Questions (FAQ’s) For Plastics Plater

What is a Plastics Plater?

A Plastics Plater is a professional who applies metallic or non-metallic coatings to plastics and other materials using electroplating, chemical plating, electroless plating, vapor deposition, anodizing, or chromating techniques.

What are the different types of plating techniques?

The different types of plating techniques include electroplating, chemical plating, electroless plating, vapor deposition, anodizing, and chromating.

What are the benefits of plating plastics?

Plating plastics can provide a number of benefits, including improved corrosion resistance, increased wear resistance, enhanced electrical conductivity, and improved appearance.

What are the career prospects for Plastics Platers?

The career prospects for Plastics Platers are good, as the demand for plated plastics is expected to grow in the coming years.

What are the educational requirements for Plastics Platers?

The educational requirements for Plastics Platers typically include a high school diploma or equivalent and some post-secondary education in chemistry or a related field.

What are the key skills for Plastics Platers?

The key skills for Plastics Platers include a strong understanding of chemistry, metallurgy, and electroplating techniques, as well as good manual dexterity and attention to detail.

What is the average salary for Plastics Platers?

The average salary for Plastics Platers varies depending on experience, location, and employer. However, according to the U.S. Bureau of Labor Statistics, the median annual salary for Electroplaters was $49,090 in May 2021.

What are the job outlook for Plastics Platers?

The job outlook for Plastics Platers is expected to be good over the next few years. As the demand for plated plastics continues to grow, so too will the need for qualified Plastics Platers.