Are you a seasoned Plate Fitter seeking a new career path? Discover our professionally built Plate Fitter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

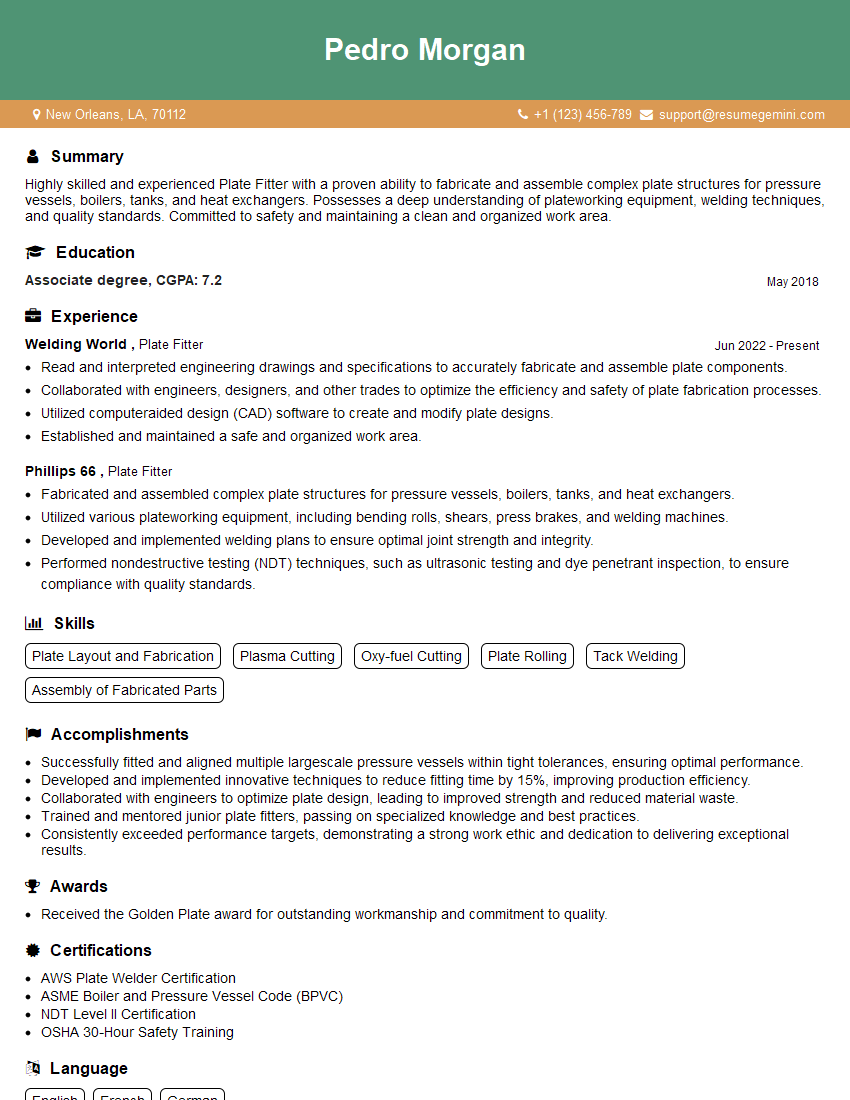

Pedro Morgan

Plate Fitter

Summary

Highly skilled and experienced Plate Fitter with a proven ability to fabricate and assemble complex plate structures for pressure vessels, boilers, tanks, and heat exchangers. Possesses a deep understanding of plateworking equipment, welding techniques, and quality standards. Committed to safety and maintaining a clean and organized work area.

Education

Associate degree

May 2018

Skills

- Plate Layout and Fabrication

- Plasma Cutting

- Oxy-fuel Cutting

- Plate Rolling

- Tack Welding

- Assembly of Fabricated Parts

Work Experience

Plate Fitter

- Read and interpreted engineering drawings and specifications to accurately fabricate and assemble plate components.

- Collaborated with engineers, designers, and other trades to optimize the efficiency and safety of plate fabrication processes.

- Utilized computeraided design (CAD) software to create and modify plate designs.

- Established and maintained a safe and organized work area.

Plate Fitter

- Fabricated and assembled complex plate structures for pressure vessels, boilers, tanks, and heat exchangers.

- Utilized various plateworking equipment, including bending rolls, shears, press brakes, and welding machines.

- Developed and implemented welding plans to ensure optimal joint strength and integrity.

- Performed nondestructive testing (NDT) techniques, such as ultrasonic testing and dye penetrant inspection, to ensure compliance with quality standards.

Accomplishments

- Successfully fitted and aligned multiple largescale pressure vessels within tight tolerances, ensuring optimal performance.

- Developed and implemented innovative techniques to reduce fitting time by 15%, improving production efficiency.

- Collaborated with engineers to optimize plate design, leading to improved strength and reduced material waste.

- Trained and mentored junior plate fitters, passing on specialized knowledge and best practices.

- Consistently exceeded performance targets, demonstrating a strong work ethic and dedication to delivering exceptional results.

Awards

- Received the Golden Plate award for outstanding workmanship and commitment to quality.

Certificates

- AWS Plate Welder Certification

- ASME Boiler and Pressure Vessel Code (BPVC)

- NDT Level II Certification

- OSHA 30-Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plate Fitter

- Highlight your skills and experience in plate layout and fabrication, plasma cutting, oxy-fuel cutting, plate rolling, tack welding, and assembly of fabricated parts.

- Showcase your knowledge of welding techniques, NDT methods, and quality standards.

- Emphasize your ability to work independently and as part of a team.

- Quantify your accomplishments and provide specific examples of your contributions.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Plate Fitter Resume

- Fabricated and assembled complex plate structures for pressure vessels, boilers, tanks, and heat exchangers.

- Utilized various plateworking equipment, including bending rolls, shears, press brakes, and welding machines.

- Developed and implemented welding plans to ensure optimal joint strength and integrity.

- Performed nondestructive testing (NDT) techniques, such as ultrasonic testing and dye penetrant inspection, to ensure compliance with quality standards.

- Read and interpreted engineering drawings and specifications to accurately fabricate and assemble plate components.

- Collaborated with engineers, designers, and other trades to optimize the efficiency and safety of plate fabrication processes.

- Utilized computer-aided design (CAD) software to create and modify plate designs.

Frequently Asked Questions (FAQ’s) For Plate Fitter

What is the role of a Plate Fitter?

Plate Fitters fabricate and assemble plate components for various industries, including pressure vessels, boilers, tanks, and heat exchangers.

What skills are required to be a successful Plate Fitter?

Skills required include plate layout and fabrication, plasma cutting, oxy-fuel cutting, plate rolling, tack welding, assembly of fabricated parts, welding techniques, and NDT methods.

What is the job outlook for Plate Fitters?

The job outlook for Plate Fitters is expected to grow in the coming years due to the increasing demand for energy and infrastructure.

What are the different industries that employ Plate Fitters?

Plate Fitters are employed in various industries, including manufacturing, construction, shipbuilding, and energy.

How can I become a Plate Fitter?

To become a Plate Fitter, you can obtain an associate degree or complete an apprenticeship program.

What is the average salary for a Plate Fitter?

The average salary for a Plate Fitter varies depending on experience and location.

What are the career advancement opportunities for Plate Fitters?

Plate Fitters can advance their careers by becoming supervisors, inspectors, or project managers.

What is the work environment like for Plate Fitters?

Plate Fitters typically work in fabrication shops or on construction sites and may be exposed to noise, fumes, and heavy equipment.