Are you a seasoned Plexiglas Former seeking a new career path? Discover our professionally built Plexiglas Former Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

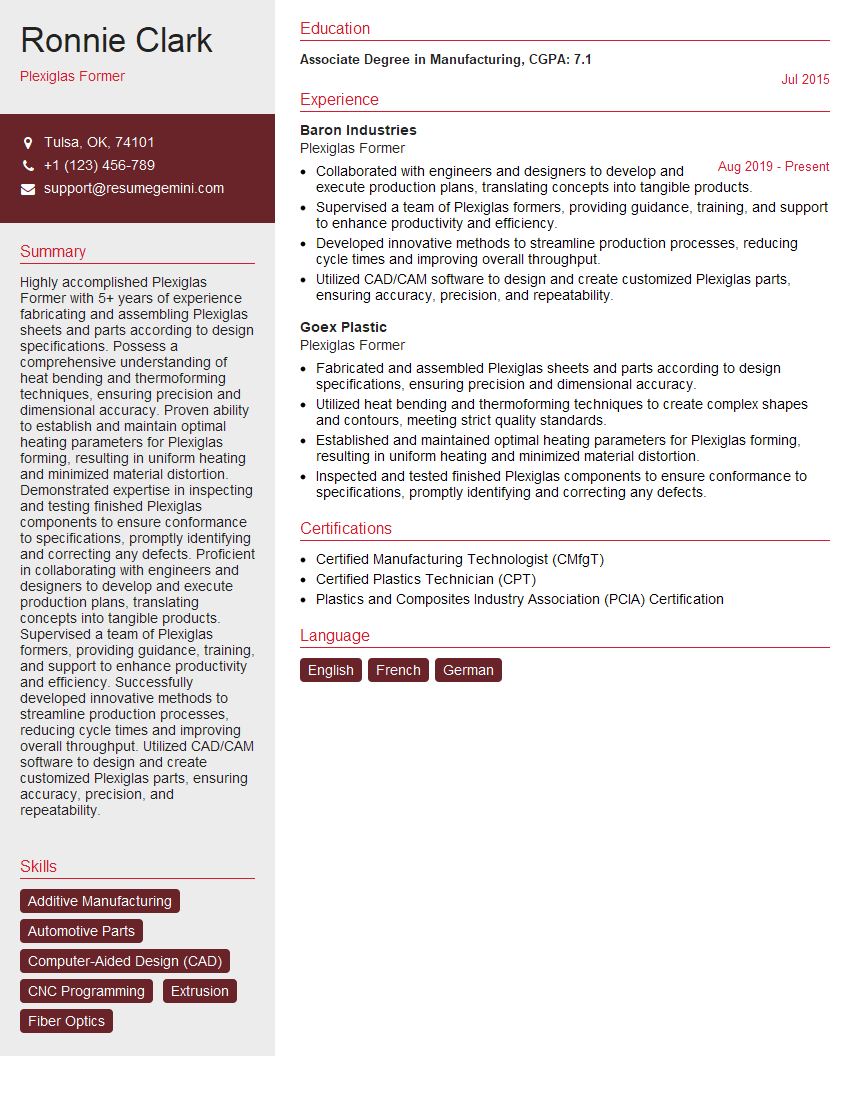

Ronnie Clark

Plexiglas Former

Summary

Highly accomplished Plexiglas Former with 5+ years of experience fabricating and assembling Plexiglas sheets and parts according to design specifications. Possess a comprehensive understanding of heat bending and thermoforming techniques, ensuring precision and dimensional accuracy. Proven ability to establish and maintain optimal heating parameters for Plexiglas forming, resulting in uniform heating and minimized material distortion. Demonstrated expertise in inspecting and testing finished Plexiglas components to ensure conformance to specifications, promptly identifying and correcting any defects. Proficient in collaborating with engineers and designers to develop and execute production plans, translating concepts into tangible products. Supervised a team of Plexiglas formers, providing guidance, training, and support to enhance productivity and efficiency. Successfully developed innovative methods to streamline production processes, reducing cycle times and improving overall throughput. Utilized CAD/CAM software to design and create customized Plexiglas parts, ensuring accuracy, precision, and repeatability.

Education

Associate Degree in Manufacturing

July 2015

Skills

- Additive Manufacturing

- Automotive Parts

- Computer-Aided Design (CAD)

- CNC Programming

- Extrusion

- Fiber Optics

Work Experience

Plexiglas Former

- Collaborated with engineers and designers to develop and execute production plans, translating concepts into tangible products.

- Supervised a team of Plexiglas formers, providing guidance, training, and support to enhance productivity and efficiency.

- Developed innovative methods to streamline production processes, reducing cycle times and improving overall throughput.

- Utilized CAD/CAM software to design and create customized Plexiglas parts, ensuring accuracy, precision, and repeatability.

Plexiglas Former

- Fabricated and assembled Plexiglas sheets and parts according to design specifications, ensuring precision and dimensional accuracy.

- Utilized heat bending and thermoforming techniques to create complex shapes and contours, meeting strict quality standards.

- Established and maintained optimal heating parameters for Plexiglas forming, resulting in uniform heating and minimized material distortion.

- Inspected and tested finished Plexiglas components to ensure conformance to specifications, promptly identifying and correcting any defects.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Plastics Technician (CPT)

- Plastics and Composites Industry Association (PCIA) Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plexiglas Former

- Highlight your technical skills and experience in heat bending and thermoforming.

- Showcase your ability to work with precision and meet tight tolerances.

- Demonstrate your knowledge of Plexiglas properties and how to work with it effectively.

- Emphasize your experience in using CAD/CAM software for design and manufacturing.

Essential Experience Highlights for a Strong Plexiglas Former Resume

- Fabricated and assembled Plexiglas sheets and parts according to design specifications, ensuring precision and dimensional accuracy

- Utilized heat bending and thermoforming techniques to create complex shapes and contours, meeting strict quality standards

- Established and maintained optimal heating parameters for Plexiglas forming, resulting in uniform heating and minimized material distortion

- Inspected and tested finished Plexiglas components to ensure conformance to specifications, promptly identifying and correcting any defects

- Collaborated with engineers and designers to develop and execute production plans, translating concepts into tangible products

Frequently Asked Questions (FAQ’s) For Plexiglas Former

What skills are required to be a Plexiglas Former?

Skills required to be a Plexiglas Former typically include experience in heat bending and thermoforming techniques, knowledge of Plexiglas properties, ability to work with precision and meet tight tolerances, and experience in using CAD/CAM software.

What is the job outlook for Plexiglas Formers?

The job outlook for Plexiglas Formers is projected to be positive, with a growth of 4% expected from 2021 to 2031.

What is the average salary for a Plexiglas Former?

The average salary for a Plexiglas Former in the United States is around $30,000 per year.

What are the career advancement opportunities for Plexiglas Formers?

Career advancement opportunities for Plexiglas Formers may include promotions to lead positions, such as Production Supervisor or Quality Control Manager.

What are the working conditions like for Plexiglas Formers?

Plexiglas Formers typically work in manufacturing environments, which may involve exposure to noise, dust, and chemicals. They may also need to work in uncomfortable positions for extended periods of time.

What are the educational requirements for Plexiglas Formers?

While there are no formal educational requirements for Plexiglas Formers, many employers prefer candidates with an associate degree in manufacturing or a related field.

What are the personal qualities that make a successful Plexiglas Former?

Successful Plexiglas Formers typically have good attention to detail, strong manual dexterity, and the ability to work independently and as part of a team.