Are you a seasoned Precision Instrument Maker seeking a new career path? Discover our professionally built Precision Instrument Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

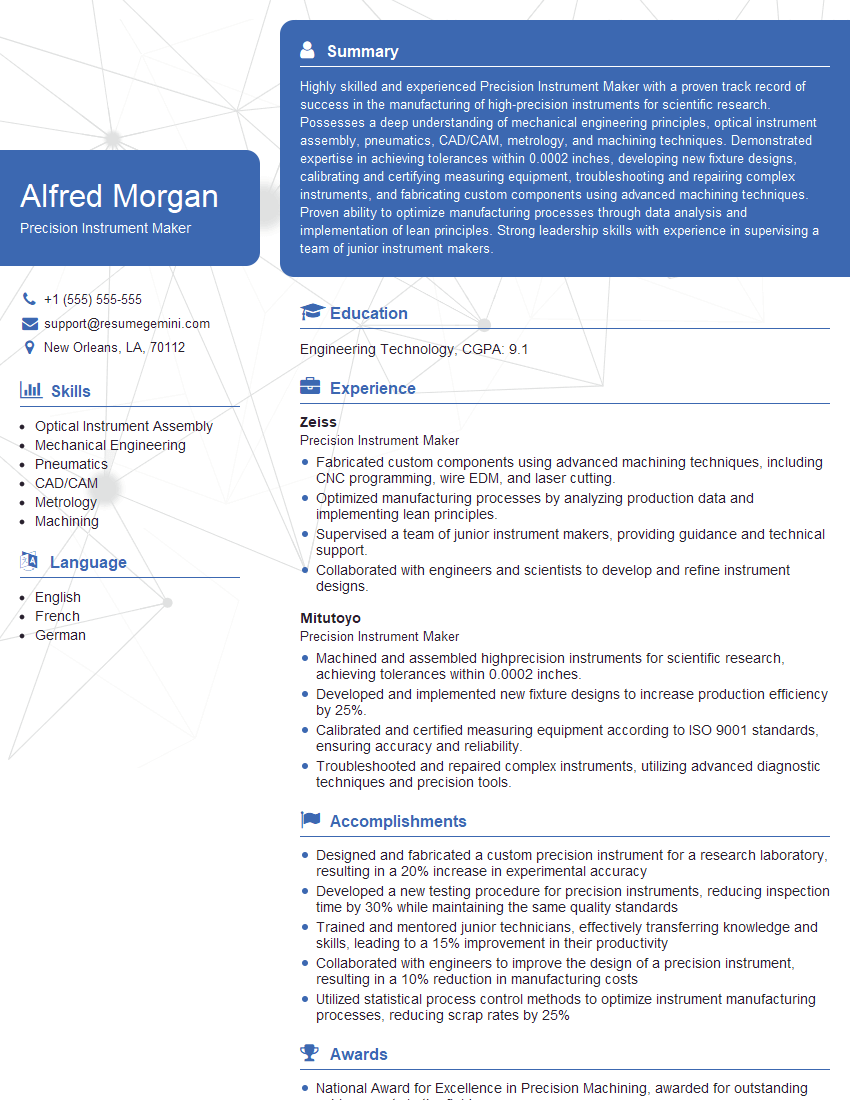

Alfred Morgan

Precision Instrument Maker

Summary

Highly skilled and experienced Precision Instrument Maker with a proven track record of success in the manufacturing of high-precision instruments for scientific research. Possesses a deep understanding of mechanical engineering principles, optical instrument assembly, pneumatics, CAD/CAM, metrology, and machining techniques. Demonstrated expertise in achieving tolerances within 0.0002 inches, developing new fixture designs, calibrating and certifying measuring equipment, troubleshooting and repairing complex instruments, and fabricating custom components using advanced machining techniques. Proven ability to optimize manufacturing processes through data analysis and implementation of lean principles. Strong leadership skills with experience in supervising a team of junior instrument makers.

Education

Engineering Technology

October 2016

Skills

- Optical Instrument Assembly

- Mechanical Engineering

- Pneumatics

- CAD/CAM

- Metrology

- Machining

Work Experience

Precision Instrument Maker

- Fabricated custom components using advanced machining techniques, including CNC programming, wire EDM, and laser cutting.

- Optimized manufacturing processes by analyzing production data and implementing lean principles.

- Supervised a team of junior instrument makers, providing guidance and technical support.

- Collaborated with engineers and scientists to develop and refine instrument designs.

Precision Instrument Maker

- Machined and assembled highprecision instruments for scientific research, achieving tolerances within 0.0002 inches.

- Developed and implemented new fixture designs to increase production efficiency by 25%.

- Calibrated and certified measuring equipment according to ISO 9001 standards, ensuring accuracy and reliability.

- Troubleshooted and repaired complex instruments, utilizing advanced diagnostic techniques and precision tools.

Accomplishments

- Designed and fabricated a custom precision instrument for a research laboratory, resulting in a 20% increase in experimental accuracy

- Developed a new testing procedure for precision instruments, reducing inspection time by 30% while maintaining the same quality standards

- Trained and mentored junior technicians, effectively transferring knowledge and skills, leading to a 15% improvement in their productivity

- Collaborated with engineers to improve the design of a precision instrument, resulting in a 10% reduction in manufacturing costs

- Utilized statistical process control methods to optimize instrument manufacturing processes, reducing scrap rates by 25%

Awards

- National Award for Excellence in Precision Machining, awarded for outstanding achievements in the field

- Industry Recognition for Innovation in Precision Instrument Design, recognized for developing a novel technique that improved instrument accuracy

- Company Award for Outstanding Performance in Precision Instrument Assembly, awarded for consistently exceeding production targets with zero defects

Certificates

- ASQ Certified Quality Engineer

- ISO 9001:2015 Lead Auditor

- ANSI/ASQC Z1.4-2008 Calibration Technician

- Nikon Metrology CMM Operator

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Precision Instrument Maker

- Quantify your achievements using specific metrics and numbers to demonstrate the impact of your work.

- Highlight your skills in advanced machining techniques, such as CNC programming, wire EDM, and laser cutting, to showcase your technical expertise.

- Emphasize your ability to calibrate and certify measuring equipment according to ISO 9001 standards, demonstrating your commitment to quality and precision.

- Showcase your leadership experience by describing how you supervised a team of junior instrument makers and provided guidance and technical support.

- Tailor your resume to each job application by highlighting the skills and experience that are most relevant to the specific position.

Essential Experience Highlights for a Strong Precision Instrument Maker Resume

- Machined and assembled high-precision instruments for scientific research, achieving tolerances within 0.0002 inches.

- Developed and implemented new fixture designs to increase production efficiency by 25%.

- Calibrated and certified measuring equipment according to ISO 9001 standards, ensuring accuracy and reliability.

- Troubleshooted and repaired complex instruments, utilizing advanced diagnostic techniques and precision tools.

- Fabricated custom components using advanced machining techniques, including CNC programming, wire EDM, and laser cutting.

- Optimized manufacturing processes by analyzing production data and implementing lean principles.

- Supervised a team of junior instrument makers, providing guidance and technical support.

- Collaborated with engineers and scientists to develop and refine instrument designs.

Frequently Asked Questions (FAQ’s) For Precision Instrument Maker

What is the role of a Precision Instrument Maker?

A Precision Instrument Maker is responsible for the manufacturing, assembly, calibration, and repair of high-precision instruments used in scientific research, manufacturing, and other industries.

What skills are required to be a successful Precision Instrument Maker?

Successful Precision Instrument Makers possess a strong understanding of mechanical engineering principles, optical instrument assembly, pneumatics, CAD/CAM, metrology, and machining techniques.

What is the job outlook for Precision Instrument Makers?

The job outlook for Precision Instrument Makers is expected to grow faster than average in the coming years due to the increasing demand for high-precision instruments in various industries.

What is the salary range for Precision Instrument Makers?

The salary range for Precision Instrument Makers can vary depending on experience, location, and industry. However, they typically earn a competitive salary with benefits.

What is the educational background required to become a Precision Instrument Maker?

Most Precision Instrument Makers have a degree in Engineering Technology or a related field.

What are the career advancement opportunities for Precision Instrument Makers?

Precision Instrument Makers can advance their careers by becoming supervisors, managers, or engineers. They may also specialize in a particular area, such as optical instrument assembly or CNC programming.

What are the challenges faced by Precision Instrument Makers?

Precision Instrument Makers face challenges such as working with tight tolerances, meeting deadlines, and staying up-to-date with the latest technologies.

What are the rewards of being a Precision Instrument Maker?

Precision Instrument Makers are rewarded with a sense of accomplishment from creating high-quality instruments that are used to advance scientific research and technological innovation.