Are you a seasoned Precision Millwright seeking a new career path? Discover our professionally built Precision Millwright Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

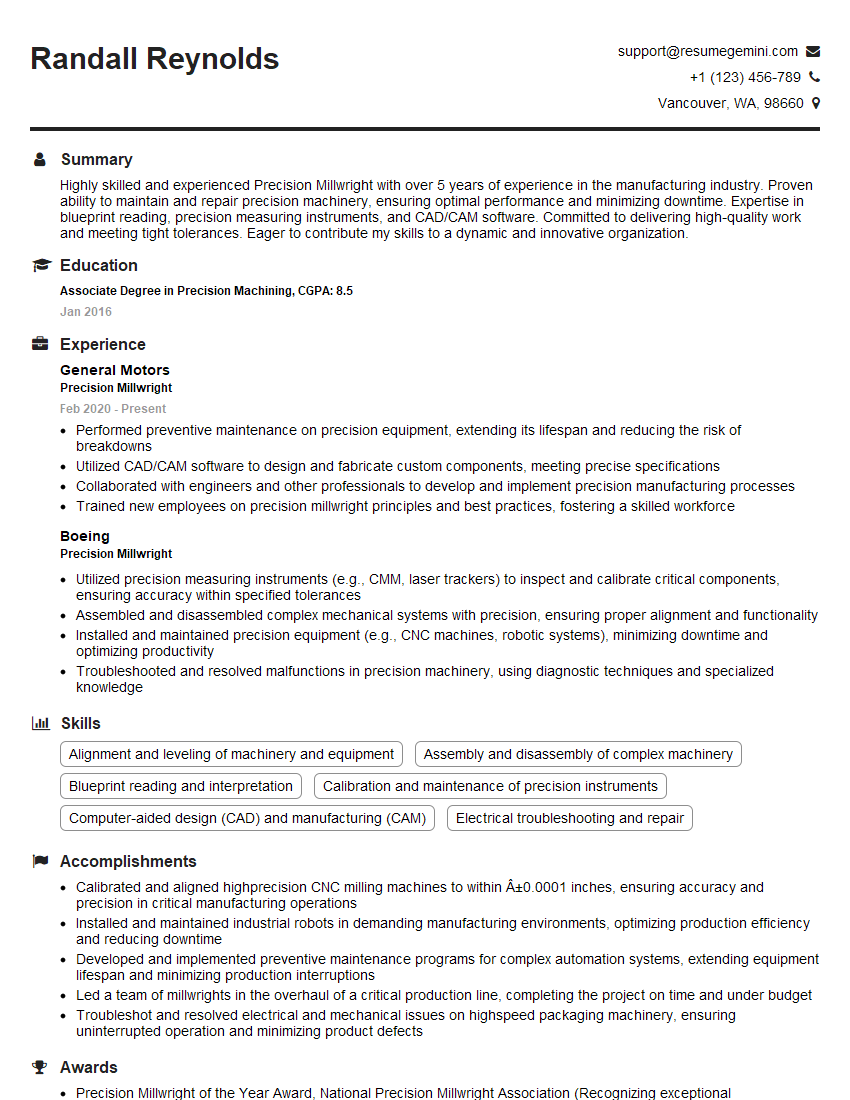

Randall Reynolds

Precision Millwright

Summary

Highly skilled and experienced Precision Millwright with over 5 years of experience in the manufacturing industry. Proven ability to maintain and repair precision machinery, ensuring optimal performance and minimizing downtime. Expertise in blueprint reading, precision measuring instruments, and CAD/CAM software. Committed to delivering high-quality work and meeting tight tolerances. Eager to contribute my skills to a dynamic and innovative organization.

Education

Associate Degree in Precision Machining

January 2016

Skills

- Alignment and leveling of machinery and equipment

- Assembly and disassembly of complex machinery

- Blueprint reading and interpretation

- Calibration and maintenance of precision instruments

- Computer-aided design (CAD) and manufacturing (CAM)

- Electrical troubleshooting and repair

Work Experience

Precision Millwright

- Performed preventive maintenance on precision equipment, extending its lifespan and reducing the risk of breakdowns

- Utilized CAD/CAM software to design and fabricate custom components, meeting precise specifications

- Collaborated with engineers and other professionals to develop and implement precision manufacturing processes

- Trained new employees on precision millwright principles and best practices, fostering a skilled workforce

Precision Millwright

- Utilized precision measuring instruments (e.g., CMM, laser trackers) to inspect and calibrate critical components, ensuring accuracy within specified tolerances

- Assembled and disassembled complex mechanical systems with precision, ensuring proper alignment and functionality

- Installed and maintained precision equipment (e.g., CNC machines, robotic systems), minimizing downtime and optimizing productivity

- Troubleshooted and resolved malfunctions in precision machinery, using diagnostic techniques and specialized knowledge

Accomplishments

- Calibrated and aligned highprecision CNC milling machines to within ±0.0001 inches, ensuring accuracy and precision in critical manufacturing operations

- Installed and maintained industrial robots in demanding manufacturing environments, optimizing production efficiency and reducing downtime

- Developed and implemented preventive maintenance programs for complex automation systems, extending equipment lifespan and minimizing production interruptions

- Led a team of millwrights in the overhaul of a critical production line, completing the project on time and under budget

- Troubleshot and resolved electrical and mechanical issues on highspeed packaging machinery, ensuring uninterrupted operation and minimizing product defects

Awards

- Precision Millwright of the Year Award, National Precision Millwright Association (Recognizing exceptional craftsmanship and contribution to the industry)

- Gold Medal in Precision Millwright Skills Competition, International Skills Organization (Demonstrating proficiency in precision machining and assembly)

- Excellence in Precision Millwright Certification Program, American Society of Precision Engineers (Recognizing comprehensive knowledge and skills in precision millwrighting)

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Machine Tool Builder (CMTB)

- Certified Precision Measurement Technician (CPMT)

- Certified Quality Engineer (CQE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Precision Millwright

- Highlight your experience and skills in precision measurement and calibration techniques.

- Quantify your accomplishments with specific metrics to demonstrate your impact.

- Showcase your problem-solving abilities and troubleshooting experience.

- Demonstrate your knowledge of industry-specific software and equipment.

- Proofread your resume carefully to eliminate any errors.

Essential Experience Highlights for a Strong Precision Millwright Resume

- Assembled and disassembled complex mechanical systems with precision, ensuring proper alignment and functionality.

- Installed and maintained precision equipment (e.g., CNC machines, robotic systems), minimizing downtime and optimizing productivity.

- Utilized precision measuring instruments (e.g., CMM, laser trackers) to inspect and calibrate critical components, ensuring accuracy within specified tolerances.

- Troubleshooted and resolved malfunctions in precision machinery, using diagnostic techniques and specialized knowledge.

- Performed preventive maintenance on precision equipment, extending its lifespan and reducing the risk of breakdowns.

- Utilized CAD/CAM software to design and fabricate custom components, meeting precise specifications.

- Collaborated with engineers and other professionals to develop and implement precision manufacturing processes.

Frequently Asked Questions (FAQ’s) For Precision Millwright

What are some common tools and equipment used by Precision Millwrights?

Precision Millwrights commonly use precision measuring instruments such as CMMs (Coordinate Measuring Machines) and laser trackers, alignment tools, levels, wrenches, and hand tools.

What is the role of a Precision Millwright in maintaining equipment accuracy?

Precision Millwrights play a crucial role in maintaining equipment accuracy by ensuring proper alignment, calibration, and maintenance of machinery and components. They use precision instruments and techniques to inspect and adjust equipment to meet specified tolerances.

How do Precision Millwrights contribute to productivity in a manufacturing setting?

Precision Millwrights contribute to productivity by ensuring that equipment operates at optimal efficiency. Through regular maintenance and troubleshooting, they minimize downtime and ensure smooth production processes.

What are the career advancement opportunities for Precision Millwrights?

Precision Millwrights can advance their careers by specializing in specific areas such as CNC programming, automation, or robotics. They can also move into supervisory or management roles with experience and additional training.

What industries employ Precision Millwrights?

Precision Millwrights are employed in various industries, including automotive, aerospace, medical device manufacturing, and electronics.

What safety precautions should Precision Millwrights observe?

Precision Millwrights must adhere to safety protocols such as wearing appropriate personal protective equipment (PPE), following lockout/tagout procedures, and maintaining a clean and organized work environment.

How does technology impact the role of Precision Millwrights?

Advancements in technology, such as automated inspection systems and predictive maintenance software, have enhanced the efficiency and accuracy of Precision Millwrights’ tasks.