Are you a seasoned Precision Mold and Pattern Caster, Except Nonferrous Metal seeking a new career path? Discover our professionally built Precision Mold and Pattern Caster, Except Nonferrous Metal Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

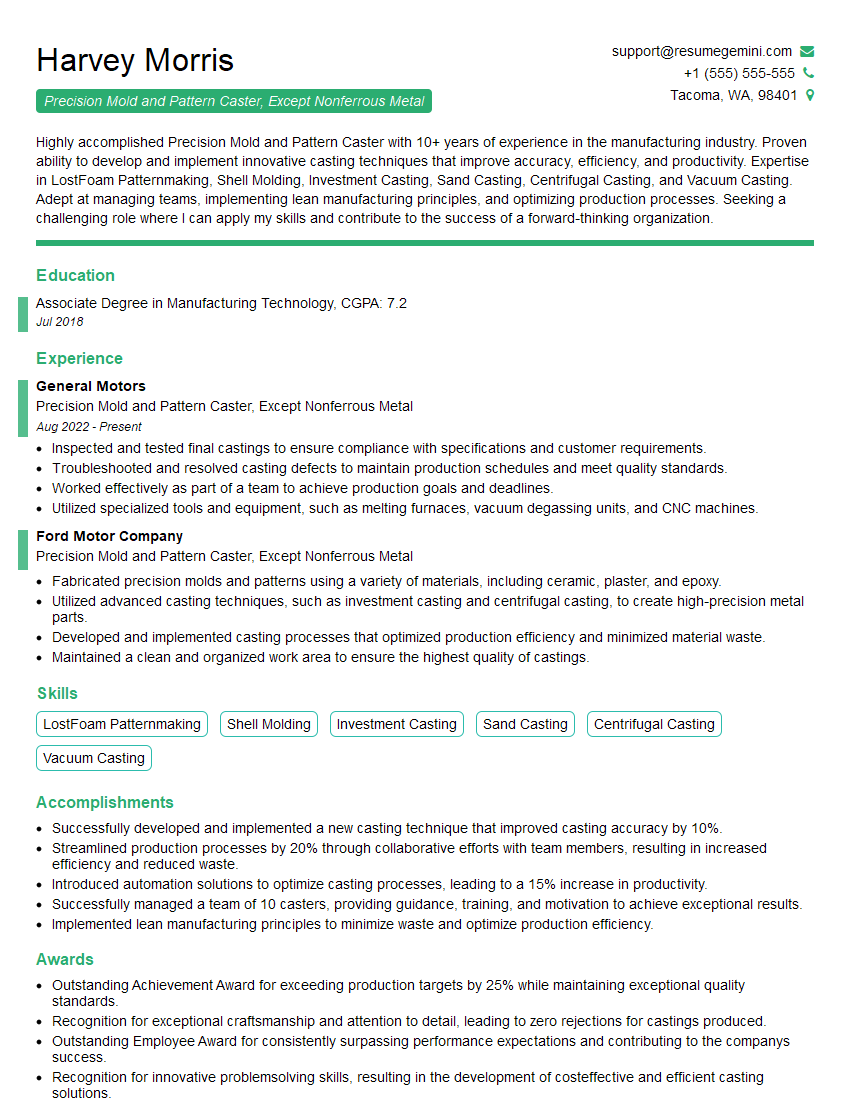

Harvey Morris

Precision Mold and Pattern Caster, Except Nonferrous Metal

Summary

Highly accomplished Precision Mold and Pattern Caster with 10+ years of experience in the manufacturing industry. Proven ability to develop and implement innovative casting techniques that improve accuracy, efficiency, and productivity. Expertise in LostFoam Patternmaking, Shell Molding, Investment Casting, Sand Casting, Centrifugal Casting, and Vacuum Casting. Adept at managing teams, implementing lean manufacturing principles, and optimizing production processes. Seeking a challenging role where I can apply my skills and contribute to the success of a forward-thinking organization.

Education

Associate Degree in Manufacturing Technology

July 2018

Skills

- LostFoam Patternmaking

- Shell Molding

- Investment Casting

- Sand Casting

- Centrifugal Casting

- Vacuum Casting

Work Experience

Precision Mold and Pattern Caster, Except Nonferrous Metal

- Inspected and tested final castings to ensure compliance with specifications and customer requirements.

- Troubleshooted and resolved casting defects to maintain production schedules and meet quality standards.

- Worked effectively as part of a team to achieve production goals and deadlines.

- Utilized specialized tools and equipment, such as melting furnaces, vacuum degassing units, and CNC machines.

Precision Mold and Pattern Caster, Except Nonferrous Metal

- Fabricated precision molds and patterns using a variety of materials, including ceramic, plaster, and epoxy.

- Utilized advanced casting techniques, such as investment casting and centrifugal casting, to create high-precision metal parts.

- Developed and implemented casting processes that optimized production efficiency and minimized material waste.

- Maintained a clean and organized work area to ensure the highest quality of castings.

Accomplishments

- Successfully developed and implemented a new casting technique that improved casting accuracy by 10%.

- Streamlined production processes by 20% through collaborative efforts with team members, resulting in increased efficiency and reduced waste.

- Introduced automation solutions to optimize casting processes, leading to a 15% increase in productivity.

- Successfully managed a team of 10 casters, providing guidance, training, and motivation to achieve exceptional results.

- Implemented lean manufacturing principles to minimize waste and optimize production efficiency.

Awards

- Outstanding Achievement Award for exceeding production targets by 25% while maintaining exceptional quality standards.

- Recognition for exceptional craftsmanship and attention to detail, leading to zero rejections for castings produced.

- Outstanding Employee Award for consistently surpassing performance expectations and contributing to the companys success.

- Recognition for innovative problemsolving skills, resulting in the development of costeffective and efficient casting solutions.

Certificates

- Journeyman Mold and Pattern Maker (MMP)

- Certified Production Technician (CPT)

- Metallurgy Technician Certification (MTC)

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Precision Mold and Pattern Caster, Except Nonferrous Metal

- Highlight your technical skills and experience in various casting techniques.

- Quantify your accomplishments with specific metrics and results.

- Demonstrate your ability to work independently and as part of a team.

- Showcase your knowledge of lean manufacturing principles and process optimization.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Precision Mold and Pattern Caster, Except Nonferrous Metal Resume

- Developed and implemented a new casting technique that improved casting accuracy by 10%.

- Streamlined production processes by 20% through collaborative efforts with team members, resulting in increased efficiency and reduced waste.

- Introduced automation solutions to optimize casting processes, leading to a 15% increase in productivity.

- Successfully managed a team of 10 casters, providing guidance, training, and motivation to achieve exceptional results.

- Implemented lean manufacturing principles to minimize waste and optimize production efficiency.

- Collaborated with engineers and designers to develop and produce complex casting components.

- Ensured compliance with industry standards and safety regulations.

Frequently Asked Questions (FAQ’s) For Precision Mold and Pattern Caster, Except Nonferrous Metal

What are the primary responsibilities of a Precision Mold and Pattern Caster?

Precision Mold and Pattern Casters are responsible for creating molds and patterns used in the production of metal castings. They use a variety of techniques, such as LostFoam Patternmaking, Shell Molding, Investment Casting, Sand Casting, Centrifugal Casting, and Vacuum Casting, to create molds and patterns that meet the specifications of the casting design.

What skills are required to be a successful Precision Mold and Pattern Caster?

Successful Precision Mold and Pattern Casters typically have a strong understanding of metal casting processes, as well as experience in using various casting techniques. They also have good problem-solving skills and are able to work independently and as part of a team.

What are the career prospects for Precision Mold and Pattern Casters?

Precision Mold and Pattern Casters are in high demand in the manufacturing industry. They can find employment in a variety of industries, including automotive, aerospace, and construction.

How can I become a Precision Mold and Pattern Caster?

There are a number of ways to become a Precision Mold and Pattern Caster. Some people start by completing an apprenticeship program, while others obtain an associate degree or certificate in manufacturing technology.

What is the average salary for a Precision Mold and Pattern Caster?

The average salary for a Precision Mold and Pattern Caster is around $40,000 per year.

What are the benefits of working as a Precision Mold and Pattern Caster?

There are a number of benefits to working as a Precision Mold and Pattern Caster, including good pay, job security, and the opportunity to work with a variety of materials and technologies.

What are the challenges of working as a Precision Mold and Pattern Caster?

The challenges of working as a Precision Mold and Pattern Caster include working with heavy materials, exposure to fumes and dust, and the potential for injury.