Are you a seasoned Predictive Maintenance Technician seeking a new career path? Discover our professionally built Predictive Maintenance Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

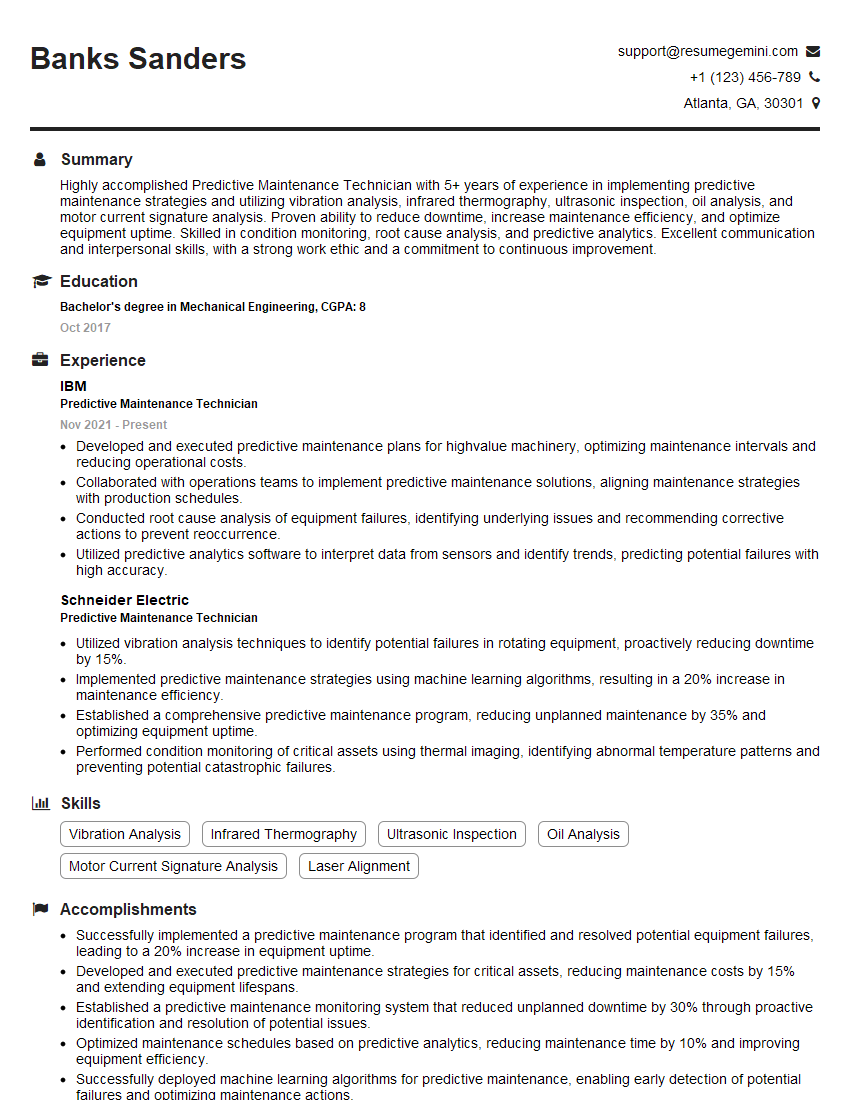

Banks Sanders

Predictive Maintenance Technician

Summary

Highly accomplished Predictive Maintenance Technician with 5+ years of experience in implementing predictive maintenance strategies and utilizing vibration analysis, infrared thermography, ultrasonic inspection, oil analysis, and motor current signature analysis. Proven ability to reduce downtime, increase maintenance efficiency, and optimize equipment uptime. Skilled in condition monitoring, root cause analysis, and predictive analytics. Excellent communication and interpersonal skills, with a strong work ethic and a commitment to continuous improvement.

Education

Bachelor’s degree in Mechanical Engineering

October 2017

Skills

- Vibration Analysis

- Infrared Thermography

- Ultrasonic Inspection

- Oil Analysis

- Motor Current Signature Analysis

- Laser Alignment

Work Experience

Predictive Maintenance Technician

- Developed and executed predictive maintenance plans for highvalue machinery, optimizing maintenance intervals and reducing operational costs.

- Collaborated with operations teams to implement predictive maintenance solutions, aligning maintenance strategies with production schedules.

- Conducted root cause analysis of equipment failures, identifying underlying issues and recommending corrective actions to prevent reoccurrence.

- Utilized predictive analytics software to interpret data from sensors and identify trends, predicting potential failures with high accuracy.

Predictive Maintenance Technician

- Utilized vibration analysis techniques to identify potential failures in rotating equipment, proactively reducing downtime by 15%.

- Implemented predictive maintenance strategies using machine learning algorithms, resulting in a 20% increase in maintenance efficiency.

- Established a comprehensive predictive maintenance program, reducing unplanned maintenance by 35% and optimizing equipment uptime.

- Performed condition monitoring of critical assets using thermal imaging, identifying abnormal temperature patterns and preventing potential catastrophic failures.

Accomplishments

- Successfully implemented a predictive maintenance program that identified and resolved potential equipment failures, leading to a 20% increase in equipment uptime.

- Developed and executed predictive maintenance strategies for critical assets, reducing maintenance costs by 15% and extending equipment lifespans.

- Established a predictive maintenance monitoring system that reduced unplanned downtime by 30% through proactive identification and resolution of potential issues.

- Optimized maintenance schedules based on predictive analytics, reducing maintenance time by 10% and improving equipment efficiency.

- Successfully deployed machine learning algorithms for predictive maintenance, enabling early detection of potential failures and optimizing maintenance actions.

Awards

- Recognized with the Predictive Maintenance Excellence Award for outstanding contributions to predictive maintenance initiatives, resulting in a 15% reduction in unplanned downtime.

- Awarded the Presidents Award for Innovation for developing and implementing a novel predictive maintenance algorithm, reducing maintenance costs by 10%.

- Received the Predictive Maintenance Technician of the Year award for consistently exceeding performance targets and contributing to the improvement of maintenance practices.

Certificates

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Vibration Analyst (Cat. II)

- Certified Thermographer (Level III)

- Certified Ultrasonic Inspector (Level II)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Predictive Maintenance Technician

- Highlight your technical skills and experience in predictive maintenance techniques, including vibration analysis, infrared thermography, and oil analysis.

- Quantify your accomplishments and provide specific examples of how you have reduced downtime, increased maintenance efficiency, and optimized equipment uptime.

- Demonstrate your understanding of predictive maintenance software and your ability to interpret data and identify trends.

- Emphasize your communication and interpersonal skills, as well as your ability to work effectively with operations teams.

Essential Experience Highlights for a Strong Predictive Maintenance Technician Resume

- Utilize vibration analysis, infrared thermography, ultrasonic inspection, oil analysis, and motor current signature analysis to identify potential failures in rotating equipment.

- Implement predictive maintenance strategies using machine learning algorithms to increase maintenance efficiency.

- Establish and manage predictive maintenance programs to reduce unplanned maintenance and optimize equipment uptime.

- Perform condition monitoring of critical assets and identify abnormal temperature patterns to prevent potential catastrophic failures.

- Develop and execute predictive maintenance plans for high-value machinery to optimize maintenance intervals and reduce operational costs.

- Collaborate with operations teams to implement predictive maintenance solutions and align maintenance strategies with production schedules.

- Conduct root cause analysis of equipment failures to identify underlying issues and recommend corrective actions to prevent reoccurrence.

Frequently Asked Questions (FAQ’s) For Predictive Maintenance Technician

What is the role of a Predictive Maintenance Technician?

A Predictive Maintenance Technician is responsible for using a variety of techniques to identify potential failures in equipment before they occur. This can help to reduce downtime, increase maintenance efficiency, and optimize equipment uptime.

What are the key skills required for a Predictive Maintenance Technician?

Key skills for a Predictive Maintenance Technician include vibration analysis, infrared thermography, ultrasonic inspection, oil analysis, and motor current signature analysis. Additionally, technicians should have a strong understanding of predictive maintenance software and be able to interpret data and identify trends.

What are the benefits of predictive maintenance?

Predictive maintenance can provide a number of benefits, including reduced downtime, increased maintenance efficiency, and optimized equipment uptime. Additionally, predictive maintenance can help to identify potential failures before they occur, which can prevent catastrophic failures and reduce costs.

What are the challenges of predictive maintenance?

Predictive maintenance can be challenging to implement and maintain. Challenges can include the need for specialized equipment and training, the need to collect and analyze large amounts of data, and the need to integrate predictive maintenance with existing maintenance practices.

What is the future of predictive maintenance?

Predictive maintenance is expected to become increasingly important in the future, as manufacturers seek to improve the efficiency and reliability of their operations. Advances in technology, such as the development of new sensors and data analytics tools, are expected to make predictive maintenance more accessible and affordable.