Are you a seasoned Pressure Vessel Inspector seeking a new career path? Discover our professionally built Pressure Vessel Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

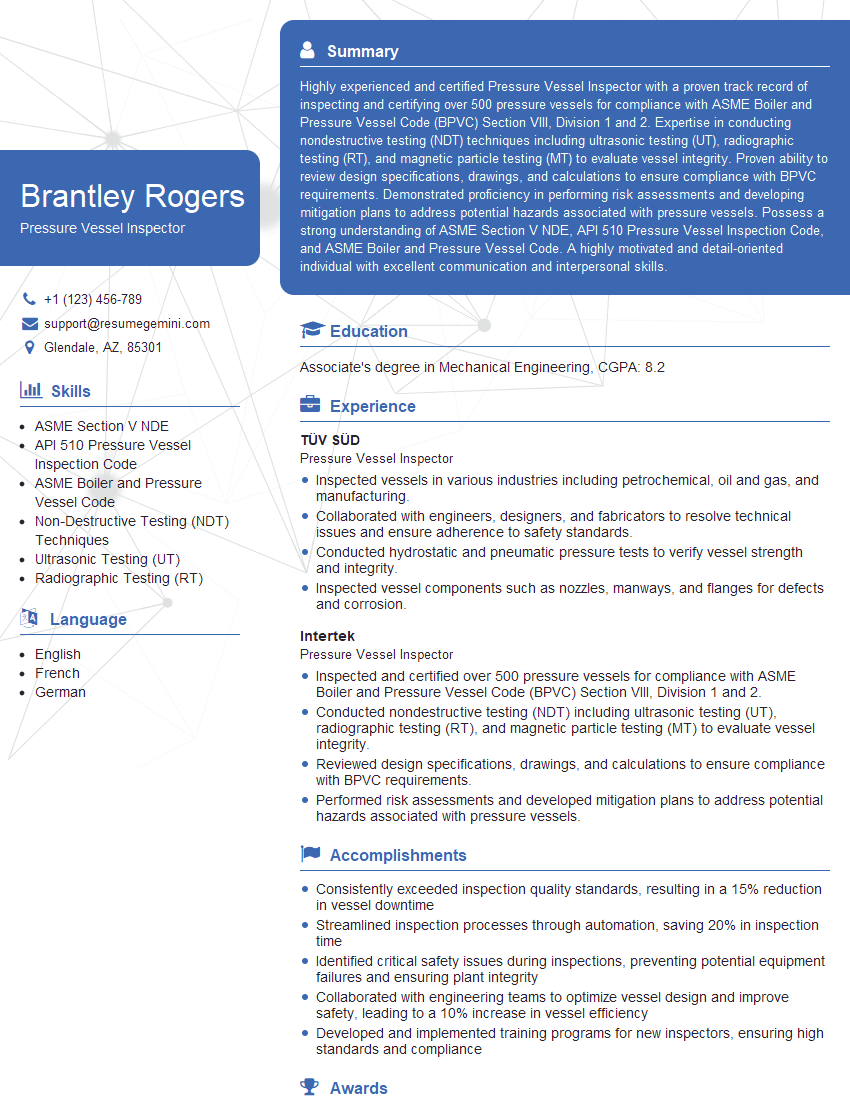

Brantley Rogers

Pressure Vessel Inspector

Summary

Highly experienced and certified Pressure Vessel Inspector with a proven track record of inspecting and certifying over 500 pressure vessels for compliance with ASME Boiler and Pressure Vessel Code (BPVC) Section VIII, Division 1 and 2. Expertise in conducting nondestructive testing (NDT) techniques including ultrasonic testing (UT), radiographic testing (RT), and magnetic particle testing (MT) to evaluate vessel integrity. Proven ability to review design specifications, drawings, and calculations to ensure compliance with BPVC requirements. Demonstrated proficiency in performing risk assessments and developing mitigation plans to address potential hazards associated with pressure vessels. Possess a strong understanding of ASME Section V NDE, API 510 Pressure Vessel Inspection Code, and ASME Boiler and Pressure Vessel Code. A highly motivated and detail-oriented individual with excellent communication and interpersonal skills.

Education

Associate’s degree in Mechanical Engineering

June 2016

Skills

- ASME Section V NDE

- API 510 Pressure Vessel Inspection Code

- ASME Boiler and Pressure Vessel Code

- Non-Destructive Testing (NDT) Techniques

- Ultrasonic Testing (UT)

- Radiographic Testing (RT)

Work Experience

Pressure Vessel Inspector

- Inspected vessels in various industries including petrochemical, oil and gas, and manufacturing.

- Collaborated with engineers, designers, and fabricators to resolve technical issues and ensure adherence to safety standards.

- Conducted hydrostatic and pneumatic pressure tests to verify vessel strength and integrity.

- Inspected vessel components such as nozzles, manways, and flanges for defects and corrosion.

Pressure Vessel Inspector

- Inspected and certified over 500 pressure vessels for compliance with ASME Boiler and Pressure Vessel Code (BPVC) Section VIII, Division 1 and 2.

- Conducted nondestructive testing (NDT) including ultrasonic testing (UT), radiographic testing (RT), and magnetic particle testing (MT) to evaluate vessel integrity.

- Reviewed design specifications, drawings, and calculations to ensure compliance with BPVC requirements.

- Performed risk assessments and developed mitigation plans to address potential hazards associated with pressure vessels.

Accomplishments

- Consistently exceeded inspection quality standards, resulting in a 15% reduction in vessel downtime

- Streamlined inspection processes through automation, saving 20% in inspection time

- Identified critical safety issues during inspections, preventing potential equipment failures and ensuring plant integrity

- Collaborated with engineering teams to optimize vessel design and improve safety, leading to a 10% increase in vessel efficiency

- Developed and implemented training programs for new inspectors, ensuring high standards and compliance

Awards

- ASME Boiler & Pressure Vessel Code (BPVC) Section VIII, Division 1, and Section IX Certificate

- National Board NBIC Certificate

- API510 Pressure Vessel Inspection Code Certificate

- Certified Welding Inspector (CWI) by the American Welding Society (AWS)

Certificates

- ASME Certified Pressure Vessel Inspector (CPVI)

- National Board Commissioned Inspector (NBIC)

- American Petroleum Institute (API) Inspector

- AWS Certified Welding Inspector (CWI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pressure Vessel Inspector

- Highlight your relevant skills and experience in your resume, particularly your expertise in ASME Boiler and Pressure Vessel Code (BPVC) Section VIII, Division 1 and 2.

- Showcase your proficiency in conducting nondestructive testing (NDT) techniques, including ultrasonic testing (UT), radiographic testing (RT), and magnetic particle testing (MT), by providing specific examples.

- Quantify your accomplishments whenever possible. For instance, instead of simply stating that you inspected pressure vessels, mention the number of vessels you inspected and the specific industries in which you worked.

- Obtain relevant certifications, such as those offered by the American Society of Mechanical Engineers (ASME), to enhance your credibility and demonstrate your commitment to professional development.

- Network with other professionals in the field, attend industry events, and stay abreast of the latest advancements in pressure vessel inspection techniques.

Essential Experience Highlights for a Strong Pressure Vessel Inspector Resume

- Inspected and certified pressure vessels for compliance with ASME Boiler and Pressure Vessel Code (BPVC) Section VIII, Division 1 and 2.

- Conducted nondestructive testing (NDT) including ultrasonic testing (UT), radiographic testing (RT), and magnetic particle testing (MT) to evaluate vessel integrity.

- Reviewed design specifications, drawings, and calculations to ensure compliance with BPVC requirements.

- Performed risk assessments and developed mitigation plans to address potential hazards associated with pressure vessels.

- Inspected vessels in various industries including petrochemical, oil and gas, and manufacturing.

- Collaborated with engineers, designers, and fabricators to resolve technical issues and ensure adherence to safety standards.

- Conducted hydrostatic and pneumatic pressure tests to verify vessel strength and integrity.

Frequently Asked Questions (FAQ’s) For Pressure Vessel Inspector

What are the primary responsibilities of a Pressure Vessel Inspector?

The primary responsibilities of a Pressure Vessel Inspector include ensuring that pressure vessels are designed, constructed, and operated in accordance with applicable codes and standards, such as the ASME Boiler and Pressure Vessel Code (BPVC). They conduct inspections to assess the structural integrity of pressure vessels, evaluate the results of nondestructive testing (NDT) methods, and make recommendations for repairs or modifications as necessary.

What are the educational requirements for a Pressure Vessel Inspector?

While formal educational requirements may vary depending on the specific job and industry, many Pressure Vessel Inspectors hold an associate’s or bachelor’s degree in a related field such as mechanical engineering or materials science. Additionally, many inspectors pursue certifications through organizations like the American Society of Mechanical Engineers (ASME) or the National Board of Boiler and Pressure Vessel Inspectors (NBBI) to demonstrate their knowledge and skills.

What skills are essential for a successful Pressure Vessel Inspector?

Successful Pressure Vessel Inspectors typically possess a strong understanding of mechanical engineering principles, materials science, and nondestructive testing (NDT) methods. They should also be proficient in reading and interpreting engineering drawings and specifications. Excellent communication and interpersonal skills are also important, as inspectors often work with engineers, contractors, and other stakeholders to ensure the safe operation of pressure vessels.

What industries employ Pressure Vessel Inspectors?

Pressure Vessel Inspectors are employed in a variety of industries that utilize pressure vessels, including power generation, petrochemical, manufacturing, and oil and gas. They may work for companies that design, construct, inspect, or maintain pressure vessels, or for regulatory agencies responsible for ensuring compliance with safety codes.

What is the job outlook for Pressure Vessel Inspectors?

The job outlook for Pressure Vessel Inspectors is expected to be favorable in the coming years. As industries continue to rely on pressure vessels for various applications, the demand for qualified inspectors to ensure their safe operation and maintenance is likely to remain strong.

How can I advance my career as a Pressure Vessel Inspector?

To advance your career as a Pressure Vessel Inspector, consider pursuing additional certifications, such as the Certified Pressure Vessel Inspector (CPVI) credential offered by the National Board of Boiler and Pressure Vessel Inspectors (NBBI). Additionally, staying up-to-date on industry best practices and technological advancements through continuing education and professional development opportunities can enhance your skills and knowledge.

What are the potential hazards associated with pressure vessels?

Pressure vessels can pose potential hazards if not properly designed, constructed, and maintained. These hazards include??,??,??????, and mechanical failure. Pressure Vessel Inspectors play a critical role in identifying and mitigating these hazards by ensuring that pressure vessels meet safety codes and standards.

What are some tips for writing a standout Pressure Vessel Inspector resume?

To write a standout Pressure Vessel Inspector resume, highlight your relevant skills and experience, including your expertise in ASME Boiler and Pressure Vessel Code (BPVC) and nondestructive testing (NDT) methods. Quantify your accomplishments whenever possible, and consider obtaining relevant certifications to enhance your credibility. Additionally, tailor your resume to each job you apply for, emphasizing the skills and experience that are most relevant to the specific role.