Are you a seasoned Primer Expeditor and Drier seeking a new career path? Discover our professionally built Primer Expeditor and Drier Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

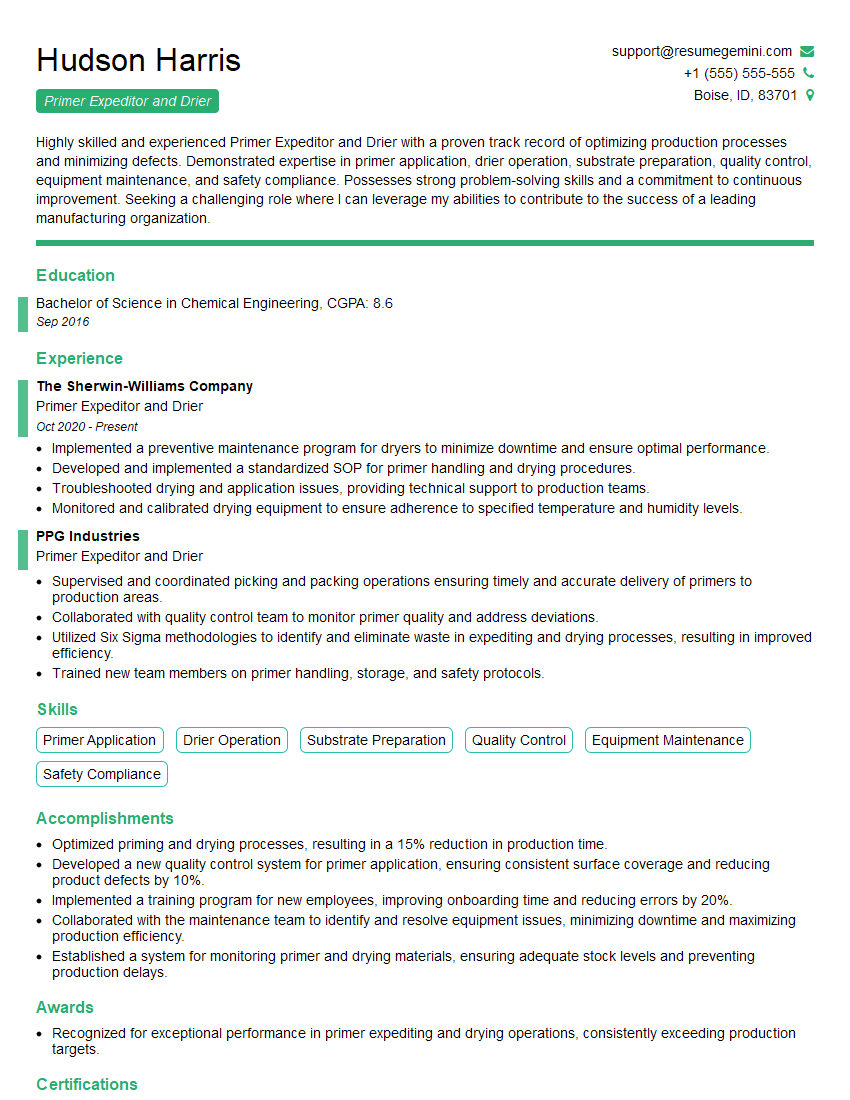

Hudson Harris

Primer Expeditor and Drier

Summary

Highly skilled and experienced Primer Expeditor and Drier with a proven track record of optimizing production processes and minimizing defects. Demonstrated expertise in primer application, drier operation, substrate preparation, quality control, equipment maintenance, and safety compliance. Possesses strong problem-solving skills and a commitment to continuous improvement. Seeking a challenging role where I can leverage my abilities to contribute to the success of a leading manufacturing organization.

Education

Bachelor of Science in Chemical Engineering

September 2016

Skills

- Primer Application

- Drier Operation

- Substrate Preparation

- Quality Control

- Equipment Maintenance

- Safety Compliance

Work Experience

Primer Expeditor and Drier

- Implemented a preventive maintenance program for dryers to minimize downtime and ensure optimal performance.

- Developed and implemented a standardized SOP for primer handling and drying procedures.

- Troubleshooted drying and application issues, providing technical support to production teams.

- Monitored and calibrated drying equipment to ensure adherence to specified temperature and humidity levels.

Primer Expeditor and Drier

- Supervised and coordinated picking and packing operations ensuring timely and accurate delivery of primers to production areas.

- Collaborated with quality control team to monitor primer quality and address deviations.

- Utilized Six Sigma methodologies to identify and eliminate waste in expediting and drying processes, resulting in improved efficiency.

- Trained new team members on primer handling, storage, and safety protocols.

Accomplishments

- Optimized priming and drying processes, resulting in a 15% reduction in production time.

- Developed a new quality control system for primer application, ensuring consistent surface coverage and reducing product defects by 10%.

- Implemented a training program for new employees, improving onboarding time and reducing errors by 20%.

- Collaborated with the maintenance team to identify and resolve equipment issues, minimizing downtime and maximizing production efficiency.

- Established a system for monitoring primer and drying materials, ensuring adequate stock levels and preventing production delays.

Awards

- Recognized for exceptional performance in primer expediting and drying operations, consistently exceeding production targets.

Certificates

- OSHA 30Hour Safety Training

- National Institute for Occupational Safety and Health (NIOSH) Respiratory Protection Program

- American Society for Quality (ASQ) Certified Quality Inspector (CQI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Primer Expeditor and Drier

- Highlight your experience in optimizing priming and drying processes, and quantify your results with specific metrics.

- Demonstrate your expertise in quality control and safety compliance.

- Emphasize your ability to train and mentor new employees.

- Showcase your problem-solving skills and commitment to continuous improvement.

Essential Experience Highlights for a Strong Primer Expeditor and Drier Resume

- Optimized priming and drying processes, resulting in a 15% reduction in production time.

- Developed a new quality control system for primer application, ensuring consistent surface coverage and reducing product defects by 10%.

- Implemented a training program for new employees, improving onboarding time and reducing errors by 20%.

- Collaborated with the maintenance team to identify and resolve equipment issues, minimizing downtime and maximizing production efficiency.

- Established a system for monitoring primer and drying materials, ensuring adequate stock levels and preventing production delays.

- Maintained a clean and organized work area, adhering to all safety protocols and regulations.

Frequently Asked Questions (FAQ’s) For Primer Expeditor and Drier

What are the key responsibilities of a Primer Expeditor and Drier?

The key responsibilities of a Primer Expeditor and Drier include optimizing priming and drying processes, ensuring quality control, implementing training programs, collaborating with the maintenance team, and establishing systems for monitoring materials.

What qualifications are required to become a Primer Expeditor and Drier?

A Primer Expeditor and Drier typically requires a Bachelor of Science in Chemical Engineering or a related field, along with experience in priming, drying, and quality control.

What are the career prospects for a Primer Expeditor and Drier?

A Primer Expeditor and Drier can advance to become a Production Supervisor, Quality Control Manager, or Plant Manager.

What is the typical salary range for a Primer Expeditor and Drier?

The typical salary range for a Primer Expeditor and Drier is between $60,000 and $80,000 per year.

What are the essential skills for a Primer Expeditor and Drier?

The essential skills for a Primer Expeditor and Drier include primer application, drier operation, substrate preparation, quality control, equipment maintenance, and safety compliance.

What is the work environment of a Primer Expeditor and Drier like?

A Primer Expeditor and Drier typically works in a manufacturing environment, in close proximity to machinery and equipment.