Are you a seasoned Printed Circuit Boards Die Set-Up Operator seeking a new career path? Discover our professionally built Printed Circuit Boards Die Set-Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

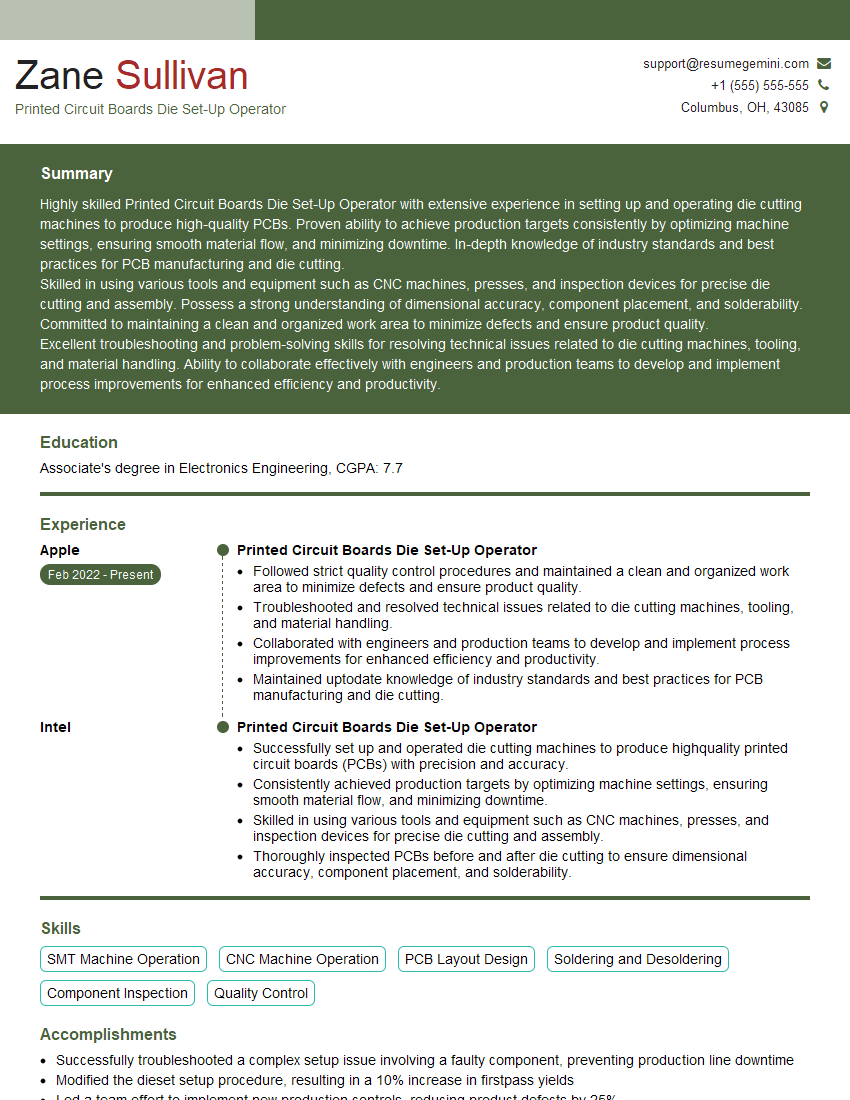

Zane Sullivan

Printed Circuit Boards Die Set-Up Operator

Summary

Highly skilled Printed Circuit Boards Die Set-Up Operator with extensive experience in setting up and operating die cutting machines to produce high-quality PCBs. Proven ability to achieve production targets consistently by optimizing machine settings, ensuring smooth material flow, and minimizing downtime. In-depth knowledge of industry standards and best practices for PCB manufacturing and die cutting.

Skilled in using various tools and equipment such as CNC machines, presses, and inspection devices for precise die cutting and assembly. Possess a strong understanding of dimensional accuracy, component placement, and solderability. Committed to maintaining a clean and organized work area to minimize defects and ensure product quality.

Excellent troubleshooting and problem-solving skills for resolving technical issues related to die cutting machines, tooling, and material handling. Ability to collaborate effectively with engineers and production teams to develop and implement process improvements for enhanced efficiency and productivity.

Education

Associate’s degree in Electronics Engineering

January 2018

Skills

- SMT Machine Operation

- CNC Machine Operation

- PCB Layout Design

- Soldering and Desoldering

- Component Inspection

- Quality Control

Work Experience

Printed Circuit Boards Die Set-Up Operator

- Followed strict quality control procedures and maintained a clean and organized work area to minimize defects and ensure product quality.

- Troubleshooted and resolved technical issues related to die cutting machines, tooling, and material handling.

- Collaborated with engineers and production teams to develop and implement process improvements for enhanced efficiency and productivity.

- Maintained uptodate knowledge of industry standards and best practices for PCB manufacturing and die cutting.

Printed Circuit Boards Die Set-Up Operator

- Successfully set up and operated die cutting machines to produce highquality printed circuit boards (PCBs) with precision and accuracy.

- Consistently achieved production targets by optimizing machine settings, ensuring smooth material flow, and minimizing downtime.

- Skilled in using various tools and equipment such as CNC machines, presses, and inspection devices for precise die cutting and assembly.

- Thoroughly inspected PCBs before and after die cutting to ensure dimensional accuracy, component placement, and solderability.

Accomplishments

- Successfully troubleshooted a complex setup issue involving a faulty component, preventing production line downtime

- Modified the dieset setup procedure, resulting in a 10% increase in firstpass yields

- Led a team effort to implement new production controls, reducing product defects by 25%

- Trained and mentored junior setup operators, ensuring smooth production line operation

- Developed a database to track and analyze machine performance, identifying areas for improvement

Awards

- Received recognition for maintaining a defectfree record in PCB fabrication for over 5000 assembly runs

- Recognized for exceptional attention to detail during a critical assembly process, ensuring all components met stringent specifications

- Awarded for optimizing the setup process, reducing lead time by 15% and improving production efficiency

- Honored for consistently exceeding performance targets and demonstrating a commitment to quality control

Certificates

- IPC-A-610 Acceptability of Electronic Assemblies

- IPC-6012 Qualification and Performance Specification for Rigid Printed Boards

- IPC-7711 Rework, Modification and Repair of Electronic Assemblies

- OSHA 30-Hour Construction Safety

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Printed Circuit Boards Die Set-Up Operator

Highlight your technical skills and experience in PCB manufacturing and die cutting.

Quantify your accomplishments with specific metrics whenever possible.

Use keywords relevant to the job description to optimize your resume for applicant tracking systems (ATS).

Proofread your resume carefully for any errors before submitting it.

Tailor your resume to each job you apply for, highlighting the skills and experience most relevant to the position.

Consider including a portfolio of your work to showcase your abilities.

Essential Experience Highlights for a Strong Printed Circuit Boards Die Set-Up Operator Resume

- Set up and operate die cutting machines to produce high-quality printed circuit boards (PCBs) with precision and accuracy.

- Consistently achieve production targets by optimizing machine settings, ensuring smooth material flow, and minimizing downtime.

- Inspect PCBs before and after die cutting to ensure dimensional accuracy, component placement, and solderability.

- Follow strict quality control procedures and maintain a clean and organized work area to minimize defects and ensure product quality.

- Troubleshoot and resolve technical issues related to die cutting machines, tooling, and material handling.

- Collaborate with engineers and production teams to develop and implement process improvements for enhanced efficiency and productivity.

- Maintain up-to-date knowledge of industry standards and best practices for PCB manufacturing and die cutting.

Frequently Asked Questions (FAQ’s) For Printed Circuit Boards Die Set-Up Operator

What are the key skills required to be a successful Printed Circuit Boards Die Set-Up Operator?

The key skills required to be a successful Printed Circuit Boards Die Set-Up Operator include: – Strong understanding of PCB manufacturing and die cutting processes – Proficiency in operating CNC machines, presses, and inspection devices – Ability to read and interpret technical drawings and specifications – Excellent troubleshooting and problem-solving skills – Commitment to quality and attention to detail – Ability to work independently and as part of a team

What are the career prospects for Printed Circuit Boards Die Set-Up Operators?

The career prospects for Printed Circuit Boards Die Set-Up Operators are generally positive. The demand for skilled PCB professionals is expected to grow in the coming years due to the increasing use of PCBs in various electronic devices. With experience and additional training, Die Set-Up Operators can advance to supervisory or management positions.

What is the average salary for Printed Circuit Boards Die Set-Up Operators?

The average salary for Printed Circuit Boards Die Set-Up Operators varies depending on factors such as experience, location, and company size. According to Indeed, the average salary for a Printed Circuit Boards Die Set-Up Operator in the United States is around $25 per hour.

What are the working conditions like for Printed Circuit Boards Die Set-Up Operators?

Printed Circuit Boards Die Set-Up Operators typically work in manufacturing environments. They may be required to stand or walk for long periods of time and lift heavy objects. The work can be repetitive, but it is also important and contributes to the production of high-quality PCBs.

What are the advancement opportunities for Printed Circuit Boards Die Set-Up Operators?

With experience and additional training, Printed Circuit Boards Die Set-Up Operators can advance to supervisory or management positions. They may also be able to specialize in a particular area of PCB manufacturing, such as design, engineering, or quality control.

What are the challenges of working as a Printed Circuit Boards Die Set-Up Operator?

The challenges of working as a Printed Circuit Boards Die Set-Up Operator include: – Working in a fast-paced and demanding environment – Meeting tight production deadlines – Ensuring the quality of PCBs – Troubleshooting and resolving technical issues – Maintaining a clean and organized work area