Are you a seasoned Printed Circuit Boards Laminator seeking a new career path? Discover our professionally built Printed Circuit Boards Laminator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

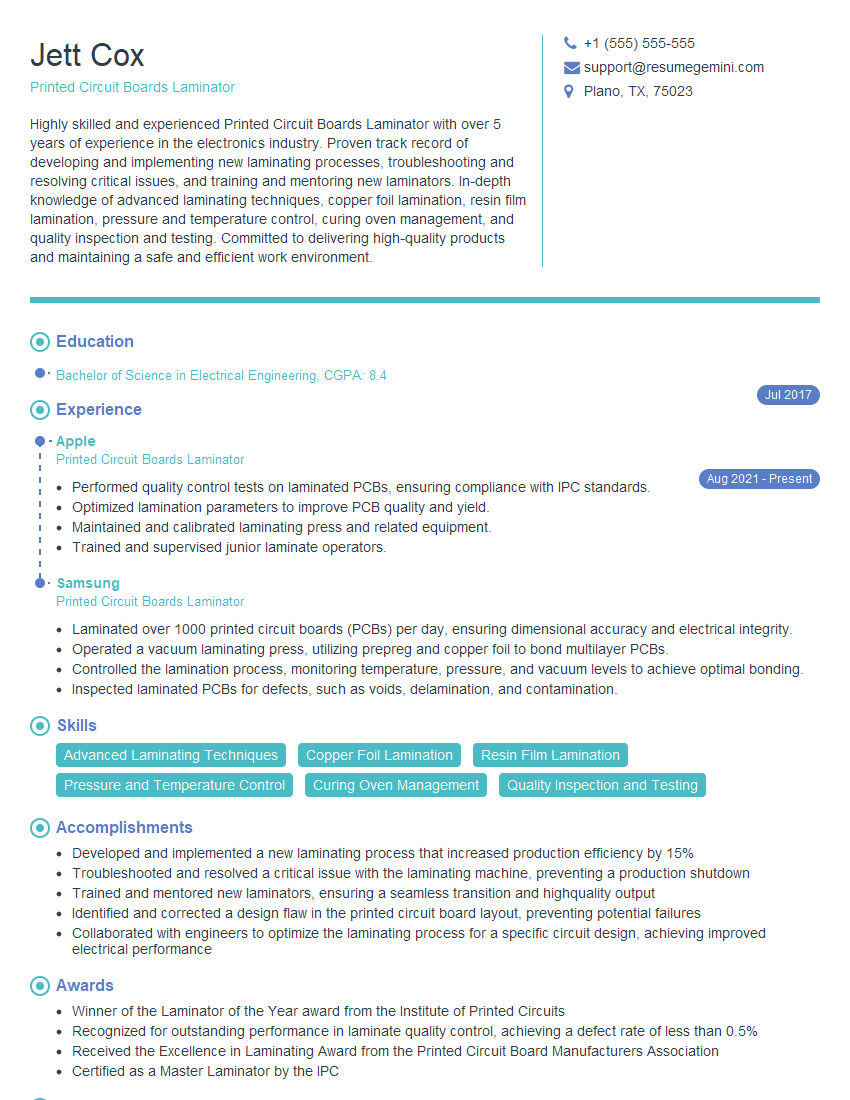

Jett Cox

Printed Circuit Boards Laminator

Summary

Highly skilled and experienced Printed Circuit Boards Laminator with over 5 years of experience in the electronics industry. Proven track record of developing and implementing new laminating processes, troubleshooting and resolving critical issues, and training and mentoring new laminators. In-depth knowledge of advanced laminating techniques, copper foil lamination, resin film lamination, pressure and temperature control, curing oven management, and quality inspection and testing. Committed to delivering high-quality products and maintaining a safe and efficient work environment.

Education

Bachelor of Science in Electrical Engineering

July 2017

Skills

- Advanced Laminating Techniques

- Copper Foil Lamination

- Resin Film Lamination

- Pressure and Temperature Control

- Curing Oven Management

- Quality Inspection and Testing

Work Experience

Printed Circuit Boards Laminator

- Performed quality control tests on laminated PCBs, ensuring compliance with IPC standards.

- Optimized lamination parameters to improve PCB quality and yield.

- Maintained and calibrated laminating press and related equipment.

- Trained and supervised junior laminate operators.

Printed Circuit Boards Laminator

- Laminated over 1000 printed circuit boards (PCBs) per day, ensuring dimensional accuracy and electrical integrity.

- Operated a vacuum laminating press, utilizing prepreg and copper foil to bond multilayer PCBs.

- Controlled the lamination process, monitoring temperature, pressure, and vacuum levels to achieve optimal bonding.

- Inspected laminated PCBs for defects, such as voids, delamination, and contamination.

Accomplishments

- Developed and implemented a new laminating process that increased production efficiency by 15%

- Troubleshooted and resolved a critical issue with the laminating machine, preventing a production shutdown

- Trained and mentored new laminators, ensuring a seamless transition and highquality output

- Identified and corrected a design flaw in the printed circuit board layout, preventing potential failures

- Collaborated with engineers to optimize the laminating process for a specific circuit design, achieving improved electrical performance

Awards

- Winner of the Laminator of the Year award from the Institute of Printed Circuits

- Recognized for outstanding performance in laminate quality control, achieving a defect rate of less than 0.5%

- Received the Excellence in Laminating Award from the Printed Circuit Board Manufacturers Association

- Certified as a Master Laminator by the IPC

Certificates

- Certified Printed Circuit Board Fabricator (CPB)

- IPC6012 Certification

- UL 94 Certification

- RoHS Compliance Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Printed Circuit Boards Laminator

- Highlight your experience in developing and implementing new laminating processes.

- Quantify your accomplishments with specific metrics, such as the percentage increase in production efficiency or the number of production shutdowns prevented.

- Demonstrate your troubleshooting and problem-solving skills by providing examples of how you have resolved critical issues.

- Emphasize your ability to train and mentor new laminators, ensuring a smooth transition and high-quality output.

Essential Experience Highlights for a Strong Printed Circuit Boards Laminator Resume

- Develop and implement new laminating processes to improve production efficiency and quality

- Troubleshoot and resolve critical issues with laminating machines to prevent production shutdowns

- Train and mentor new laminators to ensure a seamless transition and high-quality output

- Identify and correct design flaws in printed circuit board layouts to prevent potential failures

- Collaborate with engineers to optimize the laminating process for specific circuit designs to achieve improved electrical performance

- Conduct quality inspections and testing to ensure that all printed circuit boards meet specifications

- Maintain a clean and organized work area to comply with safety regulations and industry standards

Frequently Asked Questions (FAQ’s) For Printed Circuit Boards Laminator

What is a Printed Circuit Boards Laminator?

A Printed Circuit Boards Laminator is responsible for bonding together multiple layers of copper foil and resin-impregnated fiberglass cloth to create printed circuit boards (PCBs). PCBs are essential components in electronic devices, providing electrical connections between different components.

What are the key skills required for a Printed Circuit Boards Laminator?

Key skills for a Printed Circuit Boards Laminator include advanced laminating techniques, copper foil lamination, resin film lamination, pressure and temperature control, curing oven management, quality inspection and testing, and a strong understanding of electrical engineering principles.

What are the career prospects for a Printed Circuit Boards Laminator?

Printed Circuit Boards Laminators are in high demand due to the growing electronics industry. With experience and additional training, laminators can advance to supervisory or management positions or specialize in specific areas of lamination, such as high-frequency or flexible PCBs.

What is the work environment of a Printed Circuit Boards Laminator like?

Printed Circuit Boards Laminators typically work in a manufacturing environment, operating laminating machines and performing quality inspections. The work can be physically demanding and requires attention to detail and precision.

What are the safety precautions that a Printed Circuit Boards Laminator should take?

Printed Circuit Boards Laminators should wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat, to protect themselves from chemicals and fumes. They should also be aware of the potential hazards of working with electrical equipment and follow proper safety procedures.

What are the challenges faced by a Printed Circuit Boards Laminator?

Printed Circuit Boards Laminators may face challenges such as ensuring the accuracy and precision of the laminating process, troubleshooting and resolving equipment issues, and meeting production deadlines while maintaining high-quality standards.

What are the rewards of being a Printed Circuit Boards Laminator?

Printed Circuit Boards Laminators can find satisfaction in contributing to the production of high-quality electronic devices and in seeing their work used in a variety of applications. They can also enjoy the opportunity to learn about new technologies and to advance their careers in the electronics industry.