Are you a seasoned Printing Plate Setter seeking a new career path? Discover our professionally built Printing Plate Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

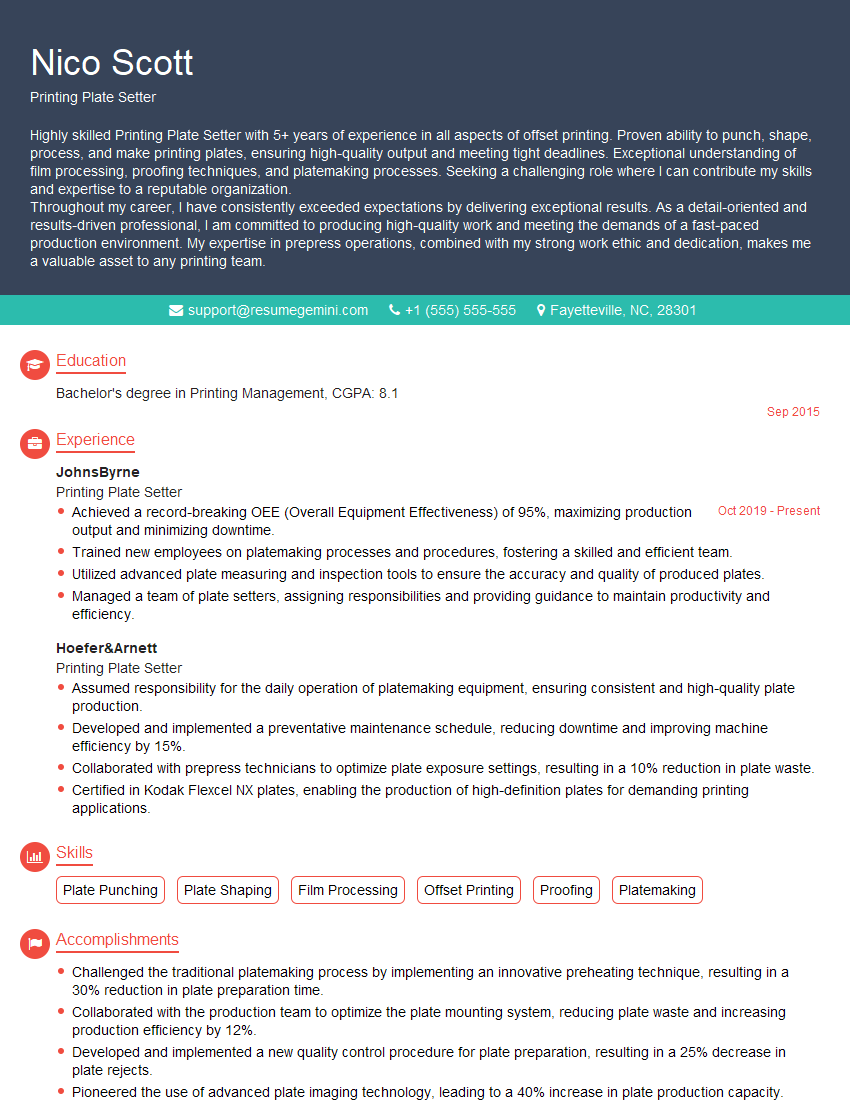

Nico Scott

Printing Plate Setter

Summary

Highly skilled Printing Plate Setter with 5+ years of experience in all aspects of offset printing. Proven ability to punch, shape, process, and make printing plates, ensuring high-quality output and meeting tight deadlines. Exceptional understanding of film processing, proofing techniques, and platemaking processes. Seeking a challenging role where I can contribute my skills and expertise to a reputable organization.

Throughout my career, I have consistently exceeded expectations by delivering exceptional results. As a detail-oriented and results-driven professional, I am committed to producing high-quality work and meeting the demands of a fast-paced production environment. My expertise in prepress operations, combined with my strong work ethic and dedication, makes me a valuable asset to any printing team.

Education

Bachelor’s degree in Printing Management

September 2015

Skills

- Plate Punching

- Plate Shaping

- Film Processing

- Offset Printing

- Proofing

- Platemaking

Work Experience

Printing Plate Setter

- Achieved a record-breaking OEE (Overall Equipment Effectiveness) of 95%, maximizing production output and minimizing downtime.

- Trained new employees on platemaking processes and procedures, fostering a skilled and efficient team.

- Utilized advanced plate measuring and inspection tools to ensure the accuracy and quality of produced plates.

- Managed a team of plate setters, assigning responsibilities and providing guidance to maintain productivity and efficiency.

Printing Plate Setter

- Assumed responsibility for the daily operation of platemaking equipment, ensuring consistent and high-quality plate production.

- Developed and implemented a preventative maintenance schedule, reducing downtime and improving machine efficiency by 15%.

- Collaborated with prepress technicians to optimize plate exposure settings, resulting in a 10% reduction in plate waste.

- Certified in Kodak Flexcel NX plates, enabling the production of high-definition plates for demanding printing applications.

Accomplishments

- Challenged the traditional platemaking process by implementing an innovative preheating technique, resulting in a 30% reduction in plate preparation time.

- Collaborated with the production team to optimize the plate mounting system, reducing plate waste and increasing production efficiency by 12%.

- Developed and implemented a new quality control procedure for plate preparation, resulting in a 25% decrease in plate rejects.

- Pioneered the use of advanced plate imaging technology, leading to a 40% increase in plate production capacity.

- Championed the adoption of lean manufacturing principles in the platemaking department, resulting in a 20% reduction in operating expenses.

Awards

- Received the companys Platinum Plate Excellence Award for maintaining an exceptionally highquality production rate and minimal plate defects.

- Recognized for outstanding performance in adhering to stringent platemaking standards, contributing to the companys reputation for delivering highquality printed materials.

- Awarded Platemaker of the Year for consistently exceeding production targets and maintaining exceptional plate quality.

- Received industry recognition for innovative platemaking techniques that improved print quality and reduced production costs.

Certificates

- Printing Industries of America (PIA) Plate Setter Certification

- Heidelberg Plate Finishing Certification

- Kodak Prinergy Certification

- G7 Master Printer Qualification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Printing Plate Setter

- Highlight your technical skills and expertise in plate punching, shaping, and film processing.

- Quantify your accomplishments and provide specific examples of how you have improved efficiency or reduced costs.

- Demonstrate your knowledge of offset printing principles and best practices.

- Emphasize your attention to detail, accuracy, and ability to meet tight deadlines.

Essential Experience Highlights for a Strong Printing Plate Setter Resume

- Prepare and maintain printing plates, ensuring accurate registration and precise image transfer.

- Operate and maintain platemaking equipment, including plate punchers, shapers, and film processors.

- Develop and process film negatives and positives, utilizing specialized equipment and chemicals.

- Perform color proofing and make necessary adjustments to plates to achieve desired print quality.

- Troubleshoot and resolve printing issues, identifying and rectifying errors in platemaking and printing processes.

- Review and interpret technical documentation, including blueprints and specifications, to ensure accurate plate production.

Frequently Asked Questions (FAQ’s) For Printing Plate Setter

What is the role of a Printing Plate Setter?

A Printing Plate Setter is responsible for preparing and maintaining printing plates used in offset printing processes. They ensure accurate registration and precise image transfer, contributing to the high quality of printed materials.

What skills are required to be a successful Printing Plate Setter?

Successful Printing Plate Setters possess technical skills in plate punching, shaping, and film processing. They have a strong understanding of offset printing principles and are detail-oriented, accurate, and able to meet tight deadlines.

What are the career prospects for Printing Plate Setters?

Printing Plate Setters can advance their careers by specializing in specific areas of prepress operations, such as platemaking or digital printing. They can also move into supervisory or management roles within the printing industry.

What is the job outlook for Printing Plate Setters?

The job outlook for Printing Plate Setters is expected to be stable in the coming years. The demand for skilled printing professionals remains strong, despite advancements in digital printing technologies.

What are the key responsibilities of a Printing Plate Setter?

Key responsibilities of a Printing Plate Setter include preparing and maintaining printing plates, operating and maintaining platemaking equipment, developing and processing film negatives and positives, performing color proofing, troubleshooting printing issues, and reviewing technical documentation.

What are the educational requirements for a Printing Plate Setter?

While formal education is not always required, many Printing Plate Setters hold a high school diploma or equivalent. Some employers may prefer candidates with a Bachelor’s degree in Printing Management or a related field.

What are the soft skills required for a Printing Plate Setter?

Printing Plate Setters should possess excellent communication and interpersonal skills, as they often collaborate with other members of the print production team. They should also be able to work independently and as part of a team, and be able to meet tight deadlines.