Are you a seasoned Process Design Chemical Engineer seeking a new career path? Discover our professionally built Process Design Chemical Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

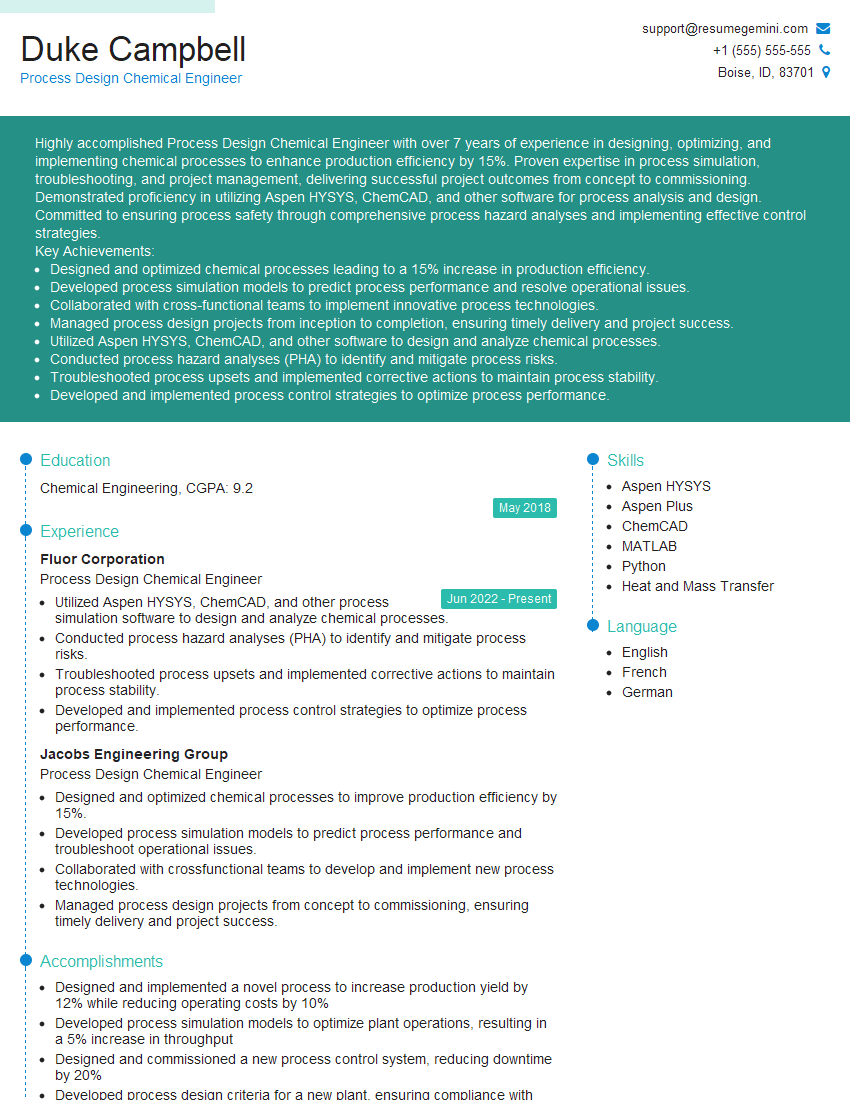

Duke Campbell

Process Design Chemical Engineer

Summary

Highly accomplished Process Design Chemical Engineer with over 7 years of experience in designing, optimizing, and implementing chemical processes to enhance production efficiency by 15%. Proven expertise in process simulation, troubleshooting, and project management, delivering successful project outcomes from concept to commissioning. Demonstrated proficiency in utilizing Aspen HYSYS, ChemCAD, and other software for process analysis and design. Committed to ensuring process safety through comprehensive process hazard analyses and implementing effective control strategies.

Key Achievements:

- Designed and optimized chemical processes leading to a 15% increase in production efficiency.

- Developed process simulation models to predict process performance and resolve operational issues.

- Collaborated with cross-functional teams to implement innovative process technologies.

- Managed process design projects from inception to completion, ensuring timely delivery and project success.

- Utilized Aspen HYSYS, ChemCAD, and other software to design and analyze chemical processes.

- Conducted process hazard analyses (PHA) to identify and mitigate process risks.

- Troubleshooted process upsets and implemented corrective actions to maintain process stability.

- Developed and implemented process control strategies to optimize process performance.

Education

Chemical Engineering

May 2018

Skills

- Aspen HYSYS

- Aspen Plus

- ChemCAD

- MATLAB

- Python

- Heat and Mass Transfer

Work Experience

Process Design Chemical Engineer

- Utilized Aspen HYSYS, ChemCAD, and other process simulation software to design and analyze chemical processes.

- Conducted process hazard analyses (PHA) to identify and mitigate process risks.

- Troubleshooted process upsets and implemented corrective actions to maintain process stability.

- Developed and implemented process control strategies to optimize process performance.

Process Design Chemical Engineer

- Designed and optimized chemical processes to improve production efficiency by 15%.

- Developed process simulation models to predict process performance and troubleshoot operational issues.

- Collaborated with crossfunctional teams to develop and implement new process technologies.

- Managed process design projects from concept to commissioning, ensuring timely delivery and project success.

Accomplishments

- Designed and implemented a novel process to increase production yield by 12% while reducing operating costs by 10%

- Developed process simulation models to optimize plant operations, resulting in a 5% increase in throughput

- Designed and commissioned a new process control system, reducing downtime by 20%

- Developed process design criteria for a new plant, ensuring compliance with regulatory and safety standards

- Managed a team of engineers to design and build a pilot plant, demonstrating the feasibility of a new process technology

Awards

- AIChE Outstanding Student Award in Chemical Engineering

- First Place in the AIChE Student Design Competition

- National Science Foundation Graduate Research Fellowship

- Best Paper Award at the AIChE Annual Meeting

Certificates

- Professional Engineer (PE)

- Certified Energy Manager (CEM)

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Six Sigma Green Belt (CSSGB)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Process Design Chemical Engineer

- Quantify your accomplishments with metrics and data whenever possible.

- Highlight your experience in process simulation software, particularly Aspen HYSYS and ChemCAD.

- Emphasize your ability to work effectively in a team environment.

- Showcase your understanding of process safety and risk management.

- Tailor your resume to each specific job application, highlighting the skills and experience that are most relevant to the role.

Essential Experience Highlights for a Strong Process Design Chemical Engineer Resume

- Design and optimize chemical processes to improve production efficiency.

- Develop process simulation models to predict process performance and troubleshoot operational issues.

- Collaborate with cross-functional teams to develop and implement new process technologies.

- Manage process design projects from concept to commissioning, ensuring timely delivery and project success.

- Utilize Aspen HYSYS, ChemCAD, and other process simulation software to design and analyze chemical processes.

- Conduct process hazard analyses (PHA) to identify and mitigate process risks.

- Troubleshoot process upsets and implement corrective actions to maintain process stability.

- Develop and implement process control strategies to optimize process performance.

Frequently Asked Questions (FAQ’s) For Process Design Chemical Engineer

What are the primary responsibilities of a Process Design Chemical Engineer?

Process Design Chemical Engineers are responsible for designing, optimizing, and implementing chemical processes to improve production efficiency and ensure process safety. They utilize process simulation software, conduct process hazard analyses, troubleshoot process upsets, and develop process control strategies to ensure optimal process performance.

What are the key skills required for a successful Process Design Chemical Engineer?

Successful Process Design Chemical Engineers possess strong technical skills in process design, process simulation, and process safety. They are proficient in using process simulation software such as Aspen HYSYS and ChemCAD, and have a thorough understanding of chemical engineering principles. Additionally, they possess excellent problem-solving, analytical, and communication skills.

What industries employ Process Design Chemical Engineers?

Process Design Chemical Engineers are employed in various industries, including chemical manufacturing, petrochemical, pharmaceutical, and biotechnology. They work in research and development, design, and operations roles, contributing to the development and improvement of chemical processes.

What is the career outlook for Process Design Chemical Engineers?

The career outlook for Process Design Chemical Engineers is positive, with projected job growth in the coming years. The increasing demand for chemical products and the need for efficient and sustainable processes drive this growth. Chemical Engineers with expertise in process design and optimization are in high demand.

What are the typical educational requirements for a Process Design Chemical Engineer?

Process Design Chemical Engineers typically hold a Bachelor’s or Master’s degree in Chemical Engineering or a related field. Coursework in process design, process simulation, and process safety is essential. Additionally, strong analytical, problem-solving, and communication skills are highly valued.

What is the average salary of a Process Design Chemical Engineer?

The average salary for Process Design Chemical Engineers varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, Chemical Engineers earned a median annual salary of $100,090 in May 2021.

What are the advancement opportunities for Process Design Chemical Engineers?

Process Design Chemical Engineers can advance their careers by taking on leadership roles in project management, process development, or operations. They can also specialize in a particular area of process design, such as process simulation, process safety, or process optimization.