Are you a seasoned Process Mold Technician seeking a new career path? Discover our professionally built Process Mold Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

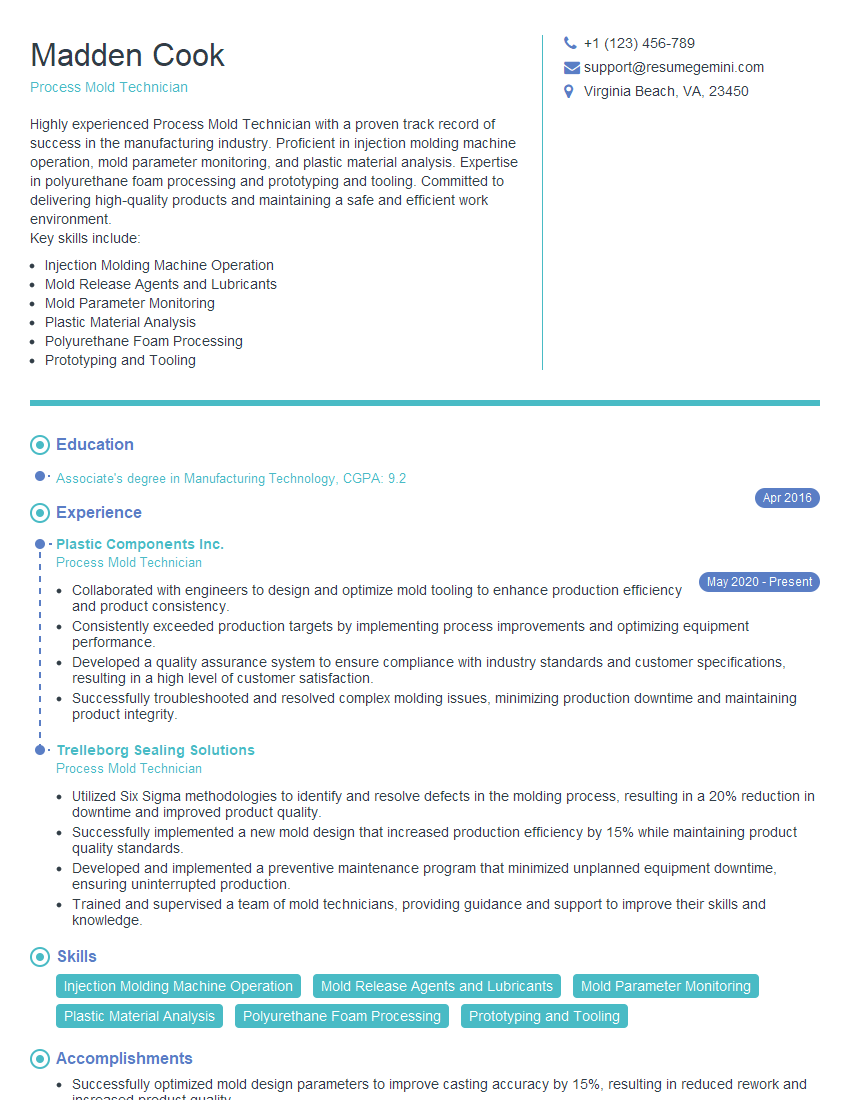

Madden Cook

Process Mold Technician

Summary

Highly experienced Process Mold Technician with a proven track record of success in the manufacturing industry. Proficient in injection molding machine operation, mold parameter monitoring, and plastic material analysis. Expertise in polyurethane foam processing and prototyping and tooling. Committed to delivering high-quality products and maintaining a safe and efficient work environment.

Key skills include:

- Injection Molding Machine Operation

- Mold Release Agents and Lubricants

- Mold Parameter Monitoring

- Plastic Material Analysis

- Polyurethane Foam Processing

- Prototyping and Tooling

Education

Associate’s degree in Manufacturing Technology

April 2016

Skills

- Injection Molding Machine Operation

- Mold Release Agents and Lubricants

- Mold Parameter Monitoring

- Plastic Material Analysis

- Polyurethane Foam Processing

- Prototyping and Tooling

Work Experience

Process Mold Technician

- Collaborated with engineers to design and optimize mold tooling to enhance production efficiency and product consistency.

- Consistently exceeded production targets by implementing process improvements and optimizing equipment performance.

- Developed a quality assurance system to ensure compliance with industry standards and customer specifications, resulting in a high level of customer satisfaction.

- Successfully troubleshooted and resolved complex molding issues, minimizing production downtime and maintaining product integrity.

Process Mold Technician

- Utilized Six Sigma methodologies to identify and resolve defects in the molding process, resulting in a 20% reduction in downtime and improved product quality.

- Successfully implemented a new mold design that increased production efficiency by 15% while maintaining product quality standards.

- Developed and implemented a preventive maintenance program that minimized unplanned equipment downtime, ensuring uninterrupted production.

- Trained and supervised a team of mold technicians, providing guidance and support to improve their skills and knowledge.

Accomplishments

- Successfully optimized mold design parameters to improve casting accuracy by 15%, resulting in reduced rework and increased product quality

- Implemented a new mold cleaning and maintenance program, leading to a 20% increase in mold lifespan and reduced downtime for maintenance

- Developed and implemented training programs for new Process Mold Technicians, ensuring a seamless onboarding process and consistent adherence to best practices

- Collaborated with design engineers to optimize mold designs for increased efficiency and reduced material waste, resulting in a 10% reduction in production costs

- Introduced a new quality control system that improved product defect detection by 30%, leading to enhanced customer satisfaction and reduced warranty claims

Awards

- Recognized with the Process Mold Technician of the Year award for consistently exceeding performance targets and maintaining highquality standards

- Received the Excellence in Process Molding award for innovative contributions to the development and implementation of new molding techniques

- Awarded the Safety Champion accolade for demonstrating exceptional adherence to safety protocols and promoting a positive safety culture within the team

Certificates

- Certified Mold Technician (CMT)

- Certified Process Technician (CPT)

- ISO 9001:2015 Certified

- Six Sigma Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Process Mold Technician

- Highlight your technical skills: Emphasize your proficiency in injection molding machine operation, mold parameter monitoring, and plastic material analysis.

- Showcase your experience: Quantify your accomplishments and provide specific examples of how you have contributed to the success of previous projects.

- Demonstrate your commitment to quality: Explain how you ensure the accuracy and precision of your work, and highlight your ability to meet or exceed quality standards.

- Tailor your resume to the job description: Carefully review the job posting and tailor your resume to match the specific requirements and keywords.

Essential Experience Highlights for a Strong Process Mold Technician Resume

- Operate and monitor injection molding machines to produce plastic components and parts.

- Ensure proper mold setup and maintenance to prevent defects and optimize production efficiency.

- Analyze plastic materials and determine appropriate processing parameters to achieve desired product quality.

- Troubleshoot and resolve molding issues to minimize downtime and maintain production schedules.

- Perform quality control inspections on finished products to ensure they meet specifications.

- Maintain a clean and organized work area, adhering to safety regulations and best practices.

- Collaborate with engineers and production team to improve processes and develop new products.

Frequently Asked Questions (FAQ’s) For Process Mold Technician

What is the role of a Process Mold Technician?

A Process Mold Technician is responsible for operating and maintaining injection molding machines to produce plastic components and parts. They ensure proper mold setup, monitor machine parameters, and analyze plastic materials to optimize production efficiency and product quality.

What are the key skills required for a Process Mold Technician?

Key skills include proficiency in injection molding machine operation, mold parameter monitoring, plastic material analysis, polyurethane foam processing, prototyping, and tooling.

What is the educational background required for a Process Mold Technician?

An Associate’s degree in Manufacturing Technology or a related field is typically required.

What are the career prospects for a Process Mold Technician?

Process Mold Technicians can advance to roles such as Molding Supervisor, Production Manager, or Quality Control Manager. With experience and additional qualifications, they can also specialize in areas such as mold design or process engineering.

What is the average salary for a Process Mold Technician?

The average salary for a Process Mold Technician can vary depending on experience, location, and industry. According to Indeed, the average salary in the United States is around $25 per hour.

What are the common challenges faced by Process Mold Technicians?

Common challenges include maintaining high production volumes while ensuring product quality, troubleshooting and resolving molding issues, and adhering to safety regulations.

What are the tips for writing a standout Process Mold Technician resume?

Highlight your technical skills, showcase your experience with specific examples, demonstrate your commitment to quality, and tailor your resume to the job description.