Are you a seasoned Production Line seeking a new career path? Discover our professionally built Production Line Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

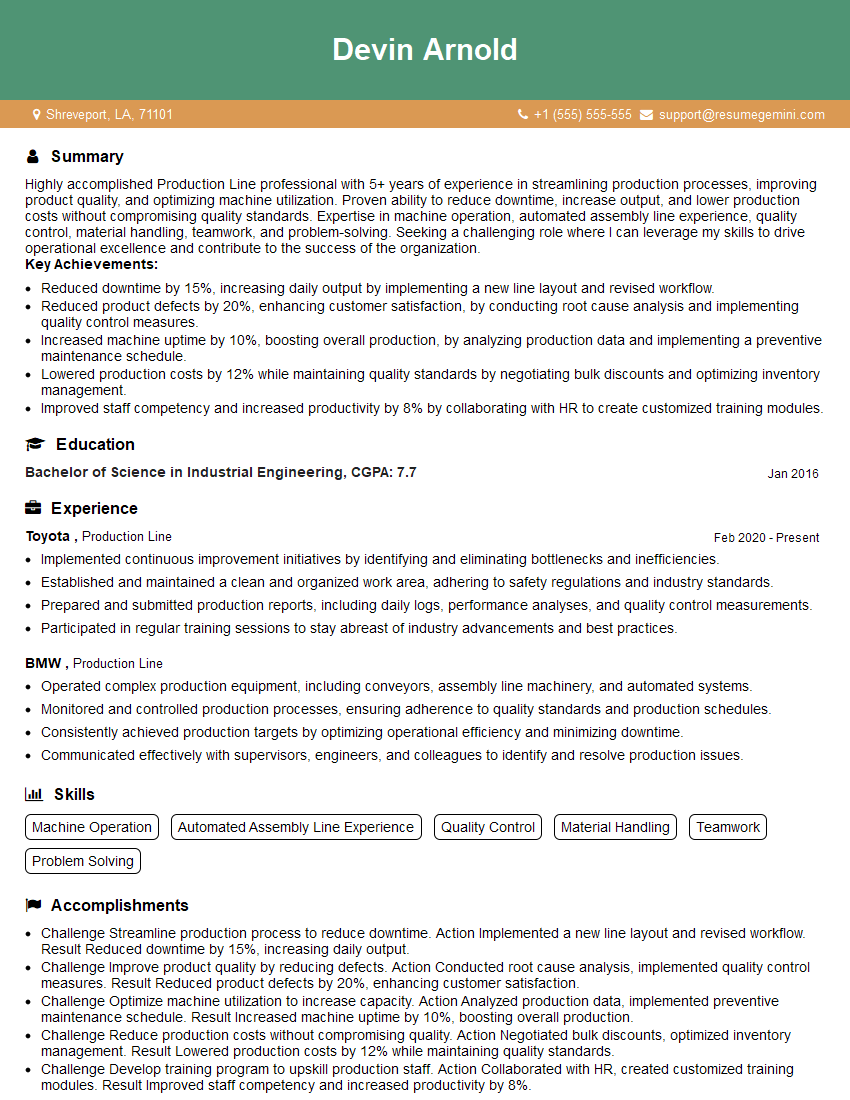

Devin Arnold

Production Line

Summary

Highly accomplished Production Line professional with 5+ years of experience in streamlining production processes, improving product quality, and optimizing machine utilization. Proven ability to reduce downtime, increase output, and lower production costs without compromising quality standards. Expertise in machine operation, automated assembly line experience, quality control, material handling, teamwork, and problem-solving. Seeking a challenging role where I can leverage my skills to drive operational excellence and contribute to the success of the organization.

Key Achievements:

- Reduced downtime by 15%, increasing daily output by implementing a new line layout and revised workflow.

- Reduced product defects by 20%, enhancing customer satisfaction, by conducting root cause analysis and implementing quality control measures.

- Increased machine uptime by 10%, boosting overall production, by analyzing production data and implementing a preventive maintenance schedule.

- Lowered production costs by 12% while maintaining quality standards by negotiating bulk discounts and optimizing inventory management.

- Improved staff competency and increased productivity by 8% by collaborating with HR to create customized training modules.

Education

Bachelor of Science in Industrial Engineering

January 2016

Skills

- Machine Operation

- Automated Assembly Line Experience

- Quality Control

- Material Handling

- Teamwork

- Problem Solving

Work Experience

Production Line

- Implemented continuous improvement initiatives by identifying and eliminating bottlenecks and inefficiencies.

- Established and maintained a clean and organized work area, adhering to safety regulations and industry standards.

- Prepared and submitted production reports, including daily logs, performance analyses, and quality control measurements.

- Participated in regular training sessions to stay abreast of industry advancements and best practices.

Production Line

- Operated complex production equipment, including conveyors, assembly line machinery, and automated systems.

- Monitored and controlled production processes, ensuring adherence to quality standards and production schedules.

- Consistently achieved production targets by optimizing operational efficiency and minimizing downtime.

- Communicated effectively with supervisors, engineers, and colleagues to identify and resolve production issues.

Accomplishments

- Challenge Streamline production process to reduce downtime. Action Implemented a new line layout and revised workflow. Result Reduced downtime by 15%, increasing daily output.

- Challenge Improve product quality by reducing defects. Action Conducted root cause analysis, implemented quality control measures. Result Reduced product defects by 20%, enhancing customer satisfaction.

- Challenge Optimize machine utilization to increase capacity. Action Analyzed production data, implemented preventive maintenance schedule. Result Increased machine uptime by 10%, boosting overall production.

- Challenge Reduce production costs without compromising quality. Action Negotiated bulk discounts, optimized inventory management. Result Lowered production costs by 12% while maintaining quality standards.

- Challenge Develop training program to upskill production staff. Action Collaborated with HR, created customized training modules. Result Improved staff competency and increased productivity by 8%.

Awards

- Production Line Excellence Award for consistently exceeding productivity targets.

- Safety Excellence Award for maintaining a spotless safety record and implementing innovative safety protocols.

- Production Line Manager of the Year Award for exceptional leadership and team management skills.

- LEAN Manufacturing Certification for expertise in implementing LEAN principles in the Production Line.

Certificates

- Certified Production Technician (CPT)

- Certified Manufacturing Technologist (CMfgT)

- Certified Lean Six Sigma Green Belt

- OSHA 30Hour General Industry Safety

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Production Line

- Quantify your accomplishments: Use specific metrics and data to demonstrate the impact of your contributions. For instance, instead of saying “Reduced downtime,” say “Reduced downtime by 15%, resulting in increased daily output by 10%.”

- Highlight your problem-solving skills: Production lines often encounter challenges. Describe how you identified problems, analyzed root causes, and implemented solutions to improve efficiency. This showcases your analytical and critical thinking abilities.

- Emphasize teamwork and collaboration: Production line roles require effective teamwork. Mention how you worked with colleagues, supervisors, and other departments to achieve common goals.

- Stay up-to-date on industry trends: The manufacturing industry is constantly evolving. Show that you are knowledgeable about emerging technologies and best practices by mentioning relevant certifications or training.

- Proofread carefully: Make sure your resume is free of errors in grammar, spelling, and formatting.

Essential Experience Highlights for a Strong Production Line Resume

- Operate and maintain production lines to ensure smooth and efficient operation.

- Monitor product quality and implement quality control measures to prevent defects.

- Analyze production data to identify areas for improvement and implement process optimizations.

- Collaborate with engineering and maintenance teams to ensure proper machine maintenance and timely repairs.

- Train and supervise production staff to ensure adherence to safety protocols and quality standards.

- Participate in continuous improvement initiatives to enhance production efficiency and reduce costs.

- Maintain a clean and organized work environment to comply with safety and regulatory standards.

Frequently Asked Questions (FAQ’s) For Production Line

What are the primary responsibilities of a Production Line worker?

Production Line workers are responsible for operating and maintaining production lines, monitoring product quality, implementing process optimizations, and ensuring safety compliance.

What skills are essential for success in this role?

Essential skills include machine operation, automated assembly line experience, quality control, material handling, teamwork, and problem-solving abilities.

What industries commonly employ Production Line workers?

Production Line workers are employed in a wide range of industries, including manufacturing, automotive, pharmaceutical, and food processing.

What is the average salary range for Production Line workers?

The average salary range varies depending on experience, location, and industry, but typically falls between $15 and $25 per hour.

What are the opportunities for career advancement?

With experience and additional training, Production Line workers can advance to roles such as Production Supervisor, Quality Control Manager, or Plant Manager.

What are the challenges of working in a production line environment?

Challenges may include repetitive tasks, working in a fast-paced environment, and meeting production targets while maintaining quality standards.

How can I prepare for a Production Line job interview?

Research the company and the specific role, practice answering common interview questions, and highlight your relevant skills and experience in your resume and cover letter.

What are the safety precautions that Production Line workers should follow?

Safety precautions include wearing appropriate safety gear, following lockout/tagout procedures, and being aware of potential hazards in the work environment.