Are you a seasoned Productivity Engineer seeking a new career path? Discover our professionally built Productivity Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

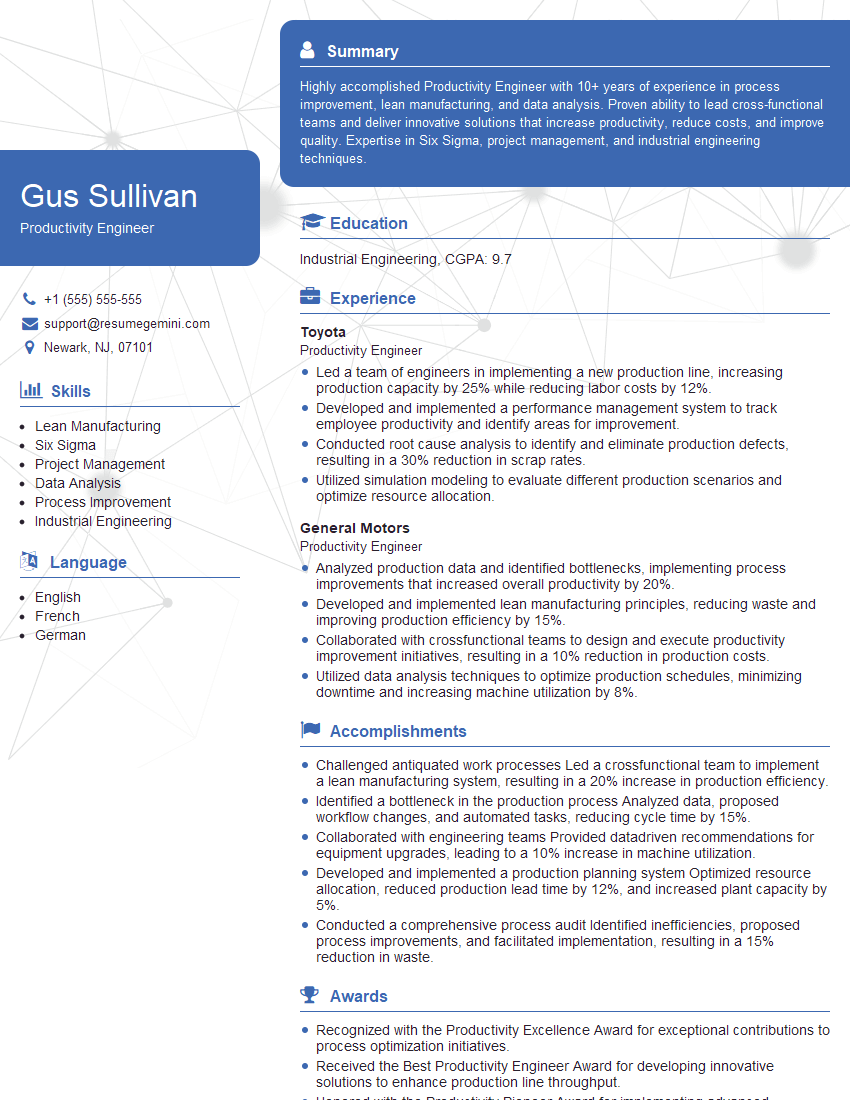

Gus Sullivan

Productivity Engineer

Summary

Highly accomplished Productivity Engineer with 10+ years of experience in process improvement, lean manufacturing, and data analysis. Proven ability to lead cross-functional teams and deliver innovative solutions that increase productivity, reduce costs, and improve quality. Expertise in Six Sigma, project management, and industrial engineering techniques.

Education

Industrial Engineering

July 2016

Skills

- Lean Manufacturing

- Six Sigma

- Project Management

- Data Analysis

- Process Improvement

- Industrial Engineering

Work Experience

Productivity Engineer

- Led a team of engineers in implementing a new production line, increasing production capacity by 25% while reducing labor costs by 12%.

- Developed and implemented a performance management system to track employee productivity and identify areas for improvement.

- Conducted root cause analysis to identify and eliminate production defects, resulting in a 30% reduction in scrap rates.

- Utilized simulation modeling to evaluate different production scenarios and optimize resource allocation.

Productivity Engineer

- Analyzed production data and identified bottlenecks, implementing process improvements that increased overall productivity by 20%.

- Developed and implemented lean manufacturing principles, reducing waste and improving production efficiency by 15%.

- Collaborated with crossfunctional teams to design and execute productivity improvement initiatives, resulting in a 10% reduction in production costs.

- Utilized data analysis techniques to optimize production schedules, minimizing downtime and increasing machine utilization by 8%.

Accomplishments

- Challenged antiquated work processes Led a crossfunctional team to implement a lean manufacturing system, resulting in a 20% increase in production efficiency.

- Identified a bottleneck in the production process Analyzed data, proposed workflow changes, and automated tasks, reducing cycle time by 15%.

- Collaborated with engineering teams Provided datadriven recommendations for equipment upgrades, leading to a 10% increase in machine utilization.

- Developed and implemented a production planning system Optimized resource allocation, reduced production lead time by 12%, and increased plant capacity by 5%.

- Conducted a comprehensive process audit Identified inefficiencies, proposed process improvements, and facilitated implementation, resulting in a 15% reduction in waste.

Awards

- Recognized with the Productivity Excellence Award for exceptional contributions to process optimization initiatives.

- Received the Best Productivity Engineer Award for developing innovative solutions to enhance production line throughput.

- Honored with the Productivity Pioneer Award for implementing advanced technologies that revolutionized the manufacturing process.

- Consistently exceeded productivity targets Recognized with the Golden Productivity Award for exceptional performance in process improvement projects.

Certificates

- Certified Lean Six Sigma Green Belt

- Certified Lean Six Sigma Black Belt

- Certified Production Technician

- Certified Industrial Engineer

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Productivity Engineer

- Quantify your accomplishments with specific metrics and results, demonstrating the impact of your contributions.

- Highlight your expertise in lean manufacturing and Six Sigma methodologies, as these are highly sought-after skills.

- Showcase your ability to work effectively in cross-functional teams and lead projects from ideation to implementation.

- Emphasize your proficiency in data analysis and simulation modeling, as these skills are essential for optimizing production processes.

Essential Experience Highlights for a Strong Productivity Engineer Resume

- Analyze production data and identify bottlenecks and opportunities for improvement

- Develop and implement lean manufacturing principles and solutions to eliminate waste and improve efficiency

- Collaborate with cross-functional teams to design and execute productivity improvement initiatives

- Utilize data analysis and simulation modeling to optimize production schedules, minimize downtime, and increase machine utilization

- Lead and manage teams of engineers in implementing new production lines and improving existing processes

- Develop and implement performance management systems to track employee productivity and identify areas for improvement

- Conduct root cause analysis to identify and eliminate production defects and improve quality

Frequently Asked Questions (FAQ’s) For Productivity Engineer

What is the role of a Productivity Engineer?

A Productivity Engineer is responsible for analyzing and improving the efficiency of production processes. They identify bottlenecks, implement lean manufacturing principles, and utilize data analysis techniques to optimize production schedules and increase machine utilization. The ultimate goal is to enhance productivity, reduce costs, and improve the overall performance of the manufacturing operation.

What qualifications are required to become a Productivity Engineer?

Typically, a Productivity Engineer requires a bachelor’s degree in Industrial Engineering or a related field. Additionally, certifications in Six Sigma, Lean Manufacturing, and Project Management are highly desirable. Experience in manufacturing operations and a strong understanding of production processes are also essential.

What are the key skills and responsibilities of a Productivity Engineer?

Key skills include proficiency in process improvement methodologies, data analysis, and project management. Responsibilities involve analyzing production data, identifying bottlenecks, developing and implementing improvement plans, and collaborating with cross-functional teams to enhance productivity and efficiency.

What is the job outlook for Productivity Engineers?

The job outlook for Productivity Engineers is expected to be favorable in the coming years. As businesses continue to strive for operational efficiency and cost reduction, the demand for skilled professionals who can analyze and improve production processes will remain high.

What is the average salary for a Productivity Engineer?

The average salary for a Productivity Engineer can vary depending on experience, location, and industry. According to Glassdoor, the average base salary for a Productivity Engineer in the United States is around $85,000 per year.

What are the career advancement opportunities for Productivity Engineers?

With experience and proven success, Productivity Engineers can advance to leadership roles such as Production Manager, Operations Manager, or Lean Manufacturing Manager. They can also specialize in specific areas such as process optimization, data analytics, or project management.

What are the challenges faced by Productivity Engineers?

Productivity Engineers often face challenges in balancing production efficiency with quality standards. They must also stay abreast of technological advancements and best practices in manufacturing to ensure continuous improvement.

What are the key trends in Productivity Engineering?

Key trends in Productivity Engineering include the adoption of Industry 4.0 technologies such as automation, data analytics, and artificial intelligence. There is also a focus on sustainability and green manufacturing practices.