Are you a seasoned Punch Operator seeking a new career path? Discover our professionally built Punch Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

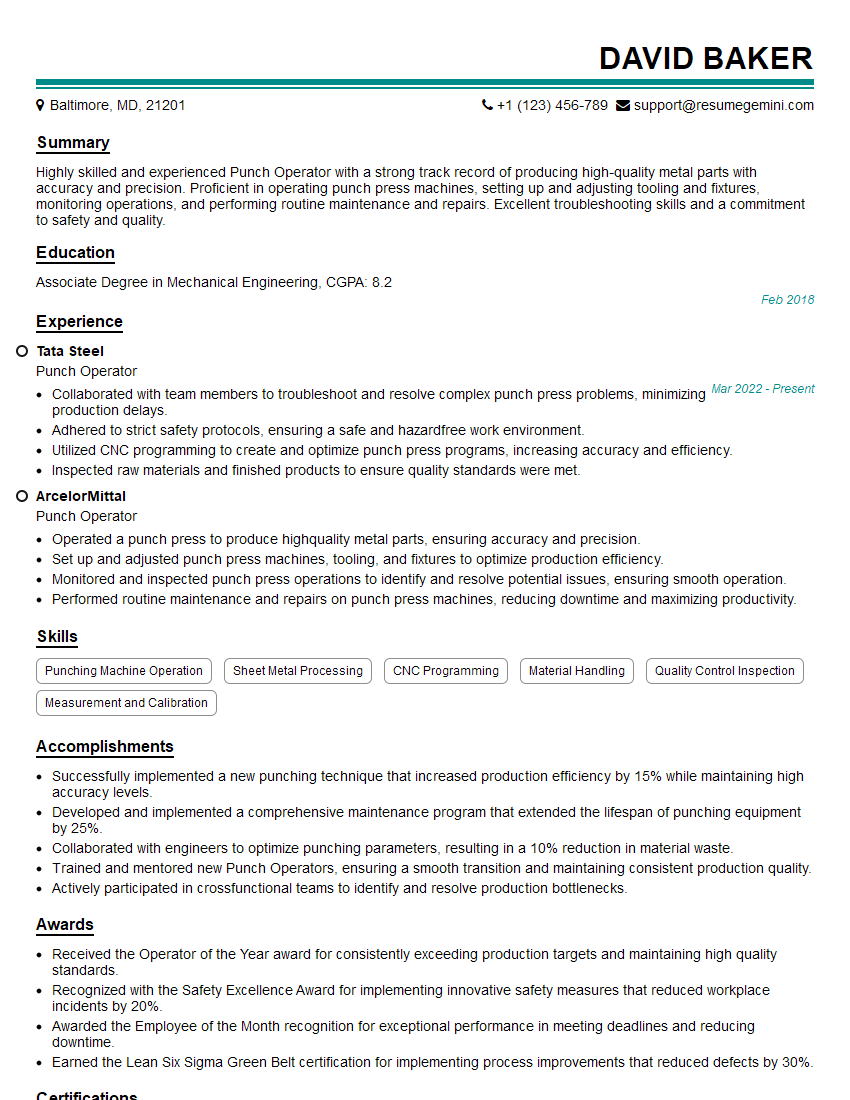

David Baker

Punch Operator

Summary

Highly skilled and experienced Punch Operator with a strong track record of producing high-quality metal parts with accuracy and precision. Proficient in operating punch press machines, setting up and adjusting tooling and fixtures, monitoring operations, and performing routine maintenance and repairs. Excellent troubleshooting skills and a commitment to safety and quality.

Education

Associate Degree in Mechanical Engineering

February 2018

Skills

- Punching Machine Operation

- Sheet Metal Processing

- CNC Programming

- Material Handling

- Quality Control Inspection

- Measurement and Calibration

Work Experience

Punch Operator

- Collaborated with team members to troubleshoot and resolve complex punch press problems, minimizing production delays.

- Adhered to strict safety protocols, ensuring a safe and hazardfree work environment.

- Utilized CNC programming to create and optimize punch press programs, increasing accuracy and efficiency.

- Inspected raw materials and finished products to ensure quality standards were met.

Punch Operator

- Operated a punch press to produce highquality metal parts, ensuring accuracy and precision.

- Set up and adjusted punch press machines, tooling, and fixtures to optimize production efficiency.

- Monitored and inspected punch press operations to identify and resolve potential issues, ensuring smooth operation.

- Performed routine maintenance and repairs on punch press machines, reducing downtime and maximizing productivity.

Accomplishments

- Successfully implemented a new punching technique that increased production efficiency by 15% while maintaining high accuracy levels.

- Developed and implemented a comprehensive maintenance program that extended the lifespan of punching equipment by 25%.

- Collaborated with engineers to optimize punching parameters, resulting in a 10% reduction in material waste.

- Trained and mentored new Punch Operators, ensuring a smooth transition and maintaining consistent production quality.

- Actively participated in crossfunctional teams to identify and resolve production bottlenecks.

Awards

- Received the Operator of the Year award for consistently exceeding production targets and maintaining high quality standards.

- Recognized with the Safety Excellence Award for implementing innovative safety measures that reduced workplace incidents by 20%.

- Awarded the Employee of the Month recognition for exceptional performance in meeting deadlines and reducing downtime.

- Earned the Lean Six Sigma Green Belt certification for implementing process improvements that reduced defects by 30%.

Certificates

- Certified Punch Operator (CPO)

- Occupational Safety and Health Administration (OSHA) 30Hour

- American Welding Society (AWS) Certified Welder

- National Institute for Metalworking Skills (NIMS) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Punch Operator

- Highlight your experience and skills in operating punch press machines, including your ability to produce high-quality parts with accuracy and precision.

- Showcase your knowledge of punch press setup, adjustment, and maintenance, as well as your ability to troubleshoot and resolve problems.

- Emphasize your commitment to safety and quality, and your ability to work effectively in a team environment.

- Consider including examples of your work, such as samples of high-quality parts you have produced or projects you have completed.

Essential Experience Highlights for a Strong Punch Operator Resume

- Operated punch press machines to produce high-quality metal parts, ensuring accuracy and precision.

- Set up and adjusted punch press machines, tooling, and fixtures to optimize production efficiency.

- Monitored and inspected punch press operations to identify and resolve potential issues, ensuring smooth operation.

- Performed routine maintenance and repairs on punch press machines, reducing downtime and maximizing productivity.

- Collaborated with team members to troubleshoot and resolve complex punch press problems, minimizing production delays.

- Adhered to strict safety protocols, ensuring a safe and hazard-free work environment.

- Utilized CNC programming to create and optimize punch press programs, increasing accuracy and efficiency.

Frequently Asked Questions (FAQ’s) For Punch Operator

What is a Punch Operator?

A Punch Operator is responsible for operating punch press machines to produce metal parts. They set up and adjust the machines, monitor operations, and perform maintenance and repairs. Punch Operators ensure that the parts produced meet quality standards and are produced efficiently.

What skills are required to be a Punch Operator?

Punch Operators typically need a high school diploma or equivalent. They should have strong mechanical skills and be able to read and interpret blueprints. They also need to be able to work independently and as part of a team. Additional skills may include CNC programming, quality control, and material handling.

What is the average salary for a Punch Operator?

The average salary for a Punch Operator in the United States is around $40,000 per year. However, salaries can vary depending on experience, location, and industry.

What are the career prospects for a Punch Operator?

Punch Operators can advance to positions such as Production Supervisor or Manufacturing Engineer. They may also start their own businesses. With additional training, they can also move into related fields such as welding or machining.

What is the work environment for a Punch Operator like?

Punch Operators typically work in factories or manufacturing plants. They may work in a variety of conditions, including hot, noisy, and dirty environments. They may also need to work overtime or on weekends.

What are the safety hazards associated with being a Punch Operator?

Punch Operators face a number of safety hazards, including: being struck by moving machinery, being exposed to loud noise, and working with sharp objects. They must follow safety procedures and wear appropriate safety gear to minimize the risk of injury.

What is the future outlook for Punch Operators?

The future outlook for Punch Operators is expected to be good. The demand for metal parts is expected to grow, and Punch Operators will be needed to produce these parts. However, automation and technological advancements may lead to a decrease in the number of jobs available.