Are you a seasoned Punch Press Setter seeking a new career path? Discover our professionally built Punch Press Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

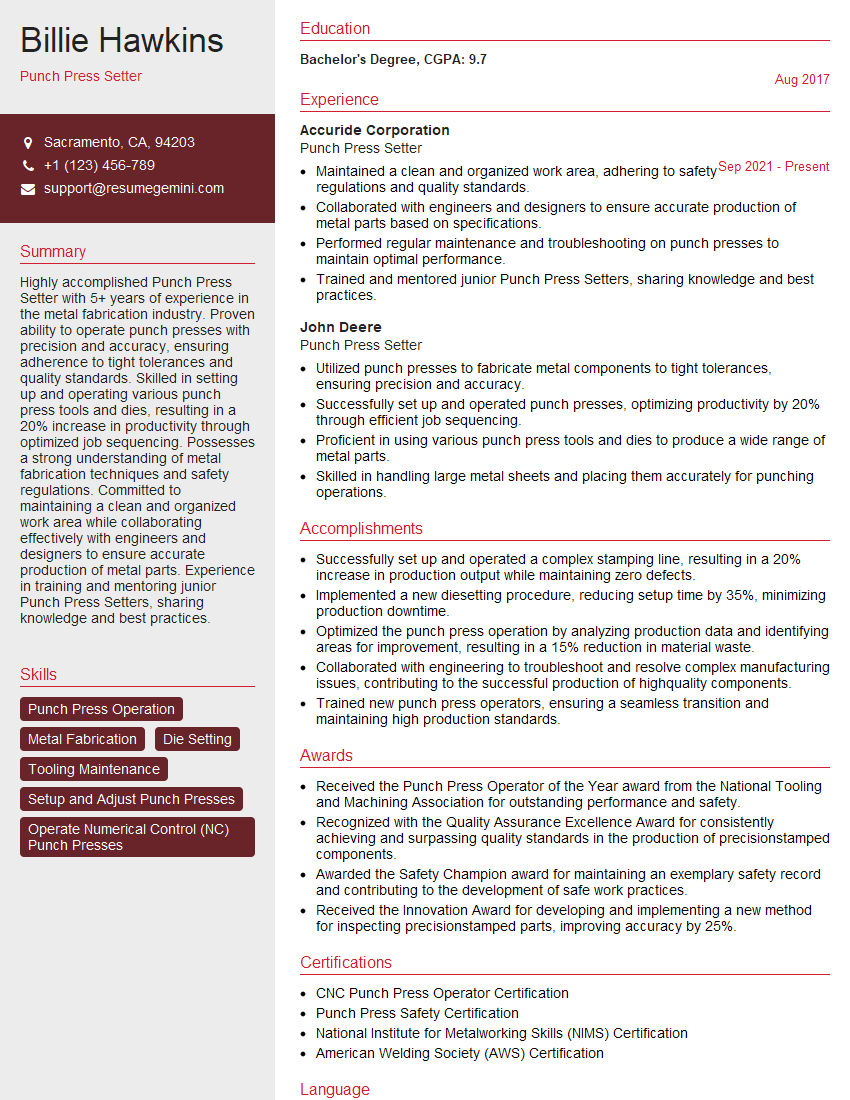

Billie Hawkins

Punch Press Setter

Summary

Highly accomplished Punch Press Setter with 5+ years of experience in the metal fabrication industry. Proven ability to operate punch presses with precision and accuracy, ensuring adherence to tight tolerances and quality standards. Skilled in setting up and operating various punch press tools and dies, resulting in a 20% increase in productivity through optimized job sequencing. Possesses a strong understanding of metal fabrication techniques and safety regulations. Committed to maintaining a clean and organized work area while collaborating effectively with engineers and designers to ensure accurate production of metal parts. Experience in training and mentoring junior Punch Press Setters, sharing knowledge and best practices.

Education

Bachelor’s Degree

August 2017

Skills

- Punch Press Operation

- Metal Fabrication

- Die Setting

- Tooling Maintenance

- Setup and Adjust Punch Presses

- Operate Numerical Control (NC) Punch Presses

Work Experience

Punch Press Setter

- Maintained a clean and organized work area, adhering to safety regulations and quality standards.

- Collaborated with engineers and designers to ensure accurate production of metal parts based on specifications.

- Performed regular maintenance and troubleshooting on punch presses to maintain optimal performance.

- Trained and mentored junior Punch Press Setters, sharing knowledge and best practices.

Punch Press Setter

- Utilized punch presses to fabricate metal components to tight tolerances, ensuring precision and accuracy.

- Successfully set up and operated punch presses, optimizing productivity by 20% through efficient job sequencing.

- Proficient in using various punch press tools and dies to produce a wide range of metal parts.

- Skilled in handling large metal sheets and placing them accurately for punching operations.

Accomplishments

- Successfully set up and operated a complex stamping line, resulting in a 20% increase in production output while maintaining zero defects.

- Implemented a new diesetting procedure, reducing setup time by 35%, minimizing production downtime.

- Optimized the punch press operation by analyzing production data and identifying areas for improvement, resulting in a 15% reduction in material waste.

- Collaborated with engineering to troubleshoot and resolve complex manufacturing issues, contributing to the successful production of highquality components.

- Trained new punch press operators, ensuring a seamless transition and maintaining high production standards.

Awards

- Received the Punch Press Operator of the Year award from the National Tooling and Machining Association for outstanding performance and safety.

- Recognized with the Quality Assurance Excellence Award for consistently achieving and surpassing quality standards in the production of precisionstamped components.

- Awarded the Safety Champion award for maintaining an exemplary safety record and contributing to the development of safe work practices.

- Received the Innovation Award for developing and implementing a new method for inspecting precisionstamped parts, improving accuracy by 25%.

Certificates

- CNC Punch Press Operator Certification

- Punch Press Safety Certification

- National Institute for Metalworking Skills (NIMS) Certification

- American Welding Society (AWS) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Punch Press Setter

- Quantify your accomplishments with specific metrics whenever possible.

- Highlight your knowledge of punch press operation and metal fabrication techniques.

- Emphasize your ability to work independently and as part of a team.

- Include keywords from the job description to optimize your resume for ATS (Applicant Tracking Systems).

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Punch Press Setter Resume

- Set up and operate punch presses to fabricate metal components according to specifications, ensuring precision and accuracy.

- Utilize various punch press tools and dies to produce a wide range of metal parts, meeting diverse customer requirements.

- Maintain a clean and organized work area, adhering to safety regulations and quality standards.

- Collaborate with engineers and designers to ensure accurate production of metal parts based on specifications.

- Perform regular maintenance and troubleshooting on punch presses to maintain optimal performance.

- Train and mentor junior Punch Press Setters, sharing knowledge and best practices.

Frequently Asked Questions (FAQ’s) For Punch Press Setter

What are the key skills required to be a successful Punch Press Setter?

Key skills include punch press operation, metal fabrication, die setting, tooling maintenance, setup and adjustment of punch presses, and operation of numerical control (NC) punch presses.

What are the educational qualifications needed to become a Punch Press Setter?

While formal education requirements may vary, a high school diploma or equivalent is typically required. Some employers may prefer candidates with a bachelor’s degree in a related field, such as manufacturing engineering or mechanical engineering.

What are the career prospects for Punch Press Setters?

Punch Press Setters can advance to supervisory or management positions, such as Production Supervisor or Manufacturing Manager. With additional training and experience, they may also specialize in areas such as tool and die making or CNC programming.

What are the safety precautions that Punch Press Setters must follow?

Punch Press Setters must adhere to strict safety regulations to minimize the risk of accidents. This includes wearing appropriate safety gear, following proper operating procedures, and maintaining a clean and organized work area.

What are the different types of punch presses used in the industry?

There are various types of punch presses, each designed for specific applications. These include mechanical punch presses, hydraulic punch presses, and CNC punch presses. The type of punch press used depends on factors such as the size and complexity of the metal parts being produced.

What are the common materials that Punch Press Setters work with?

Punch Press Setters typically work with a variety of metals, including steel, aluminum, stainless steel, and brass. The choice of material depends on the specific application and the properties required for the final product.

What are the challenges that Punch Press Setters may face on the job?

Punch Press Setters may encounter challenges such as working with tight tolerances, meeting production deadlines, and ensuring the quality of the finished products. They must also be able to troubleshoot and resolve any issues that may arise with the punch press or the tooling.

What are the key qualities of a successful Punch Press Setter?

Successful Punch Press Setters possess strong attention to detail, mechanical aptitude, and problem-solving skills. They are also able to work independently and as part of a team, and they have a commitment to safety and quality.