Are you a seasoned Quality Control Associate (QC Associate) seeking a new career path? Discover our professionally built Quality Control Associate (QC Associate) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

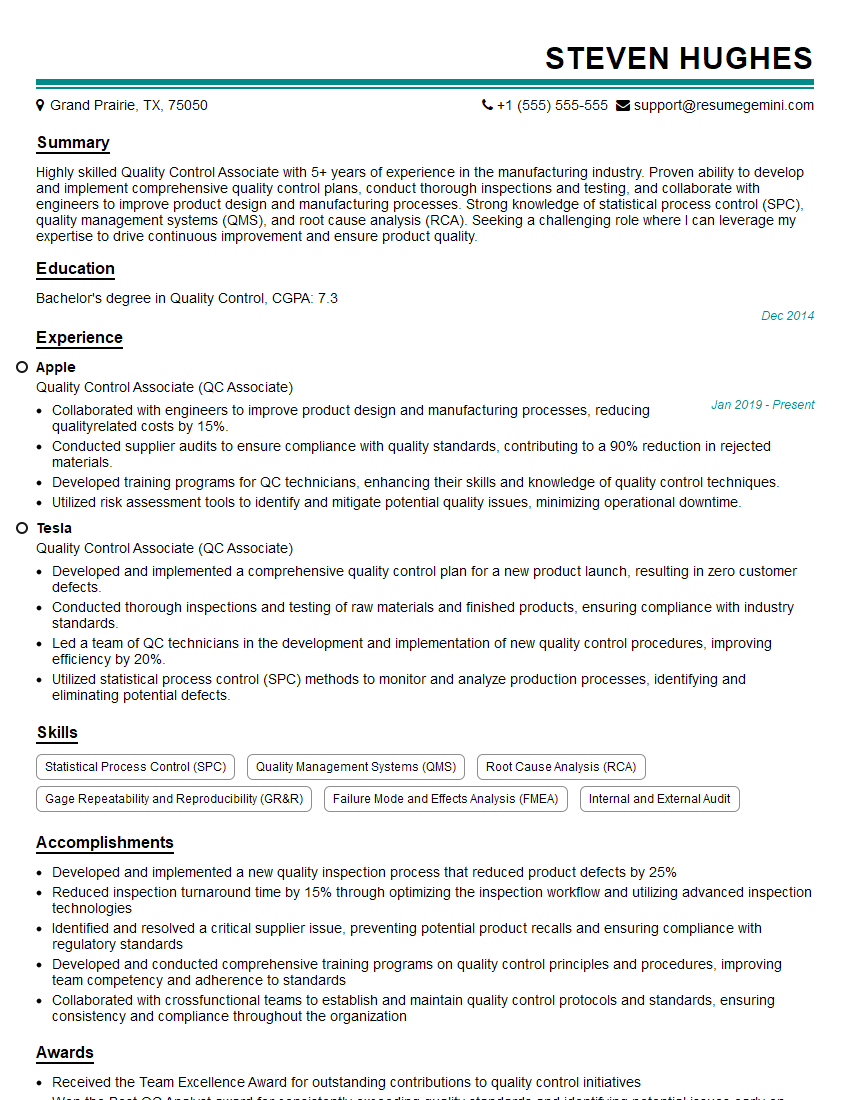

Steven Hughes

Quality Control Associate (QC Associate)

Summary

Highly skilled Quality Control Associate with 5+ years of experience in the manufacturing industry. Proven ability to develop and implement comprehensive quality control plans, conduct thorough inspections and testing, and collaborate with engineers to improve product design and manufacturing processes. Strong knowledge of statistical process control (SPC), quality management systems (QMS), and root cause analysis (RCA). Seeking a challenging role where I can leverage my expertise to drive continuous improvement and ensure product quality.

Education

Bachelor’s degree in Quality Control

December 2014

Skills

- Statistical Process Control (SPC)

- Quality Management Systems (QMS)

- Root Cause Analysis (RCA)

- Gage Repeatability and Reproducibility (GR&R)

- Failure Mode and Effects Analysis (FMEA)

- Internal and External Audit

Work Experience

Quality Control Associate (QC Associate)

- Collaborated with engineers to improve product design and manufacturing processes, reducing qualityrelated costs by 15%.

- Conducted supplier audits to ensure compliance with quality standards, contributing to a 90% reduction in rejected materials.

- Developed training programs for QC technicians, enhancing their skills and knowledge of quality control techniques.

- Utilized risk assessment tools to identify and mitigate potential quality issues, minimizing operational downtime.

Quality Control Associate (QC Associate)

- Developed and implemented a comprehensive quality control plan for a new product launch, resulting in zero customer defects.

- Conducted thorough inspections and testing of raw materials and finished products, ensuring compliance with industry standards.

- Led a team of QC technicians in the development and implementation of new quality control procedures, improving efficiency by 20%.

- Utilized statistical process control (SPC) methods to monitor and analyze production processes, identifying and eliminating potential defects.

Accomplishments

- Developed and implemented a new quality inspection process that reduced product defects by 25%

- Reduced inspection turnaround time by 15% through optimizing the inspection workflow and utilizing advanced inspection technologies

- Identified and resolved a critical supplier issue, preventing potential product recalls and ensuring compliance with regulatory standards

- Developed and conducted comprehensive training programs on quality control principles and procedures, improving team competency and adherence to standards

- Collaborated with crossfunctional teams to establish and maintain quality control protocols and standards, ensuring consistency and compliance throughout the organization

Awards

- Received the Team Excellence Award for outstanding contributions to quality control initiatives

- Won the Best QC Analyst award for consistently exceeding quality standards and identifying potential issues early on

- Recognized for Exceptional Quality Assurance by the industry association for maintaining high quality standards throughout the production process

- Received the Quality Champion Award for implementing innovative quality improvement programs that significantly enhanced overall quality performance

Certificates

- Certified Quality Auditor (CQA)

- Certified Quality Engineer (CQE)

- Certified Six Sigma Black Belt (CSSBB)

- Certified Quality Inspector (CQI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Quality Control Associate (QC Associate)

- Highlight your experience and skills in quality control, including your knowledge of SPC, QMS, and RCA.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Proofread your resume carefully for any errors in grammar or spelling.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Consider including a cover letter that introduces yourself and explains why you are interested in the position and company.

Essential Experience Highlights for a Strong Quality Control Associate (QC Associate) Resume

- Develop and implement comprehensive quality control plans to ensure product quality and compliance with industry standards.

- Conduct thorough inspections and testing of raw materials and finished products using a variety of techniques and equipment.

- Analyze quality data to identify trends, patterns, and potential defects, and recommend corrective actions.

- Collaborate with engineers to improve product design and manufacturing processes, reducing quality-related costs and improving efficiency.

- Conduct supplier audits to ensure compliance with quality standards and identify potential risks.

- Provide training to QC technicians on quality control techniques and best practices.

- Utilize risk assessment tools to identify and mitigate potential quality issues, minimizing operational downtime.

Frequently Asked Questions (FAQ’s) For Quality Control Associate (QC Associate)

What is the role of a Quality Control Associate?

Quality Control Associates are responsible for ensuring that products meet quality standards and comply with industry regulations. They conduct inspections, tests, and audits to identify and correct defects, and they work with engineers to improve product design and manufacturing processes.

What are the qualifications for becoming a Quality Control Associate?

Most Quality Control Associates have a bachelor’s degree in quality control, engineering, or a related field. They also have experience in quality control techniques, such as SPC, QMS, and RCA.

What are the job prospects for Quality Control Associates?

The job outlook for Quality Control Associates is expected to grow faster than average in the coming years. This is due to the increasing demand for quality control in the manufacturing industry.

What are the challenges of working as a Quality Control Associate?

Quality Control Associates can face challenges such as dealing with tight deadlines, working in a fast-paced environment, and making decisions that can have a significant impact on the company.

What are the rewards of working as a Quality Control Associate?

Quality Control Associates can find rewards in the satisfaction of knowing that they are helping to ensure the quality of products and protecting consumers. They can also enjoy a sense of accomplishment when they identify and correct defects, and they can have the opportunity to make a difference in the company.

What are the advancement opportunities for Quality Control Associates?

Quality Control Associates can advance to positions such as Quality Control Manager, Quality Assurance Manager, or Director of Quality.